SUSPENSION

27

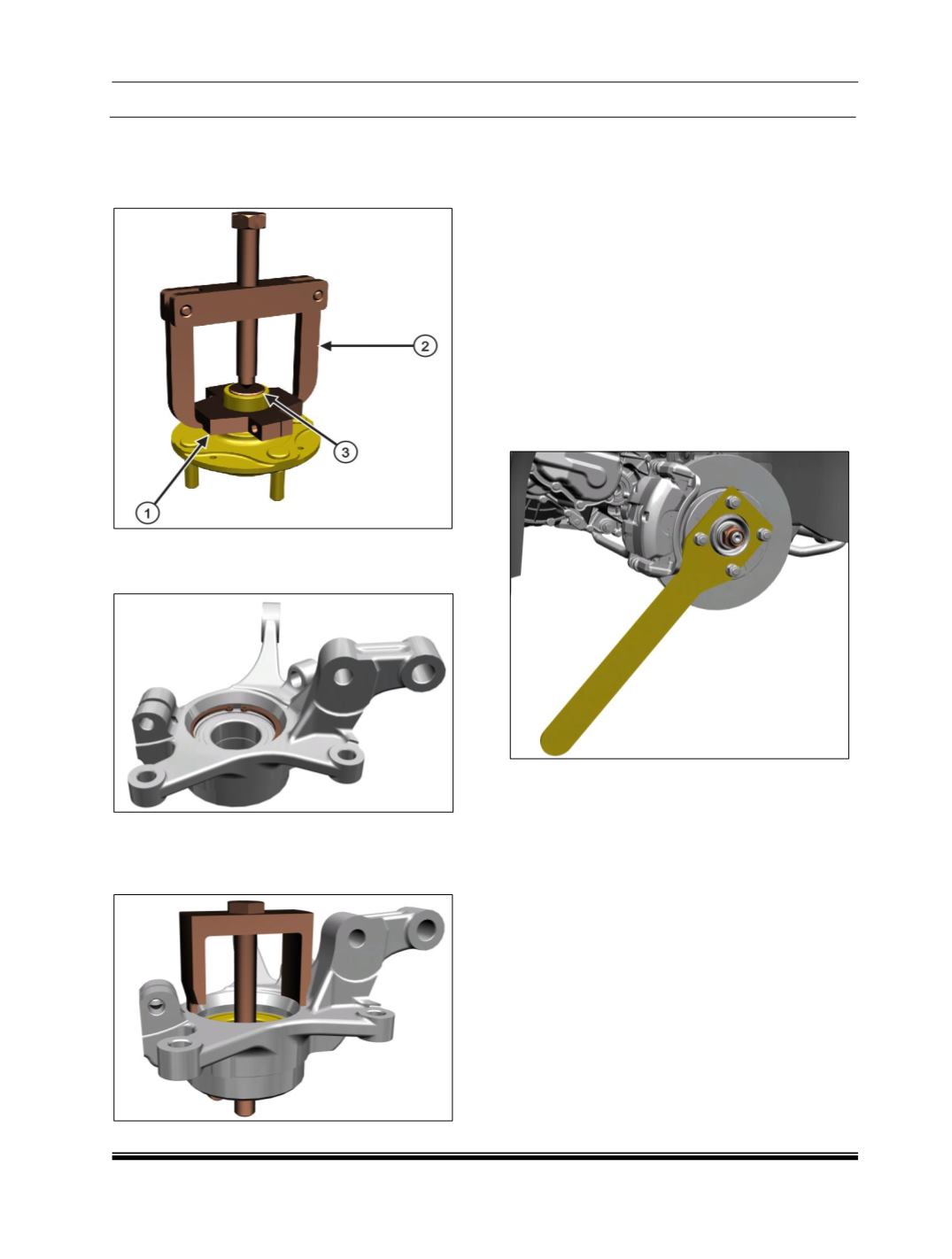

19. Using clamp (1) part No. 2779 5890 3303

puller (2) part No. 2654 5890 3508 and rest

pad (3) part No. 2702 5890 2612 remove inner

race of bearing from the hub.

FIG. 30

20. Remove circlip from knuckle.

FIG. 31

21. Pull out knuckle bearing using puller part No.

2779 5890 3302.

FIG. 32

INSTALLATION:

1. Follow the above steps in reverse order in ap-

propriate sequence for its assembly.

NOTE:

If the disc surface is uneven showing rough

marks, grooves - machine it to the specified limit;

measure the run out on dia 220 w.r.t. hub and

disc resting face.

Punch mark around bolt hole where run out on

dia 220 is at low point.

Align low point on disc and high point on hub

while assembly. Assemble with countersunk

screws.

2. Tighten drive shaft nut 23 to 26 kg.m torque

and lock by staking.

FIG. 33

3. Ensure that oil seal in transaxle is not damaged

while fitting drive shaft.

PRECAUTION:

Use a new hub bearing and new circlip, oil the

bearing housing in knuckle carrier and hub itself.

Old bearing, even if serviceable cannot be reused.