SUSPENSION

39

ASSEMBLY:

Note:

Check the condition of the components

before assembly and replace if found

damage.

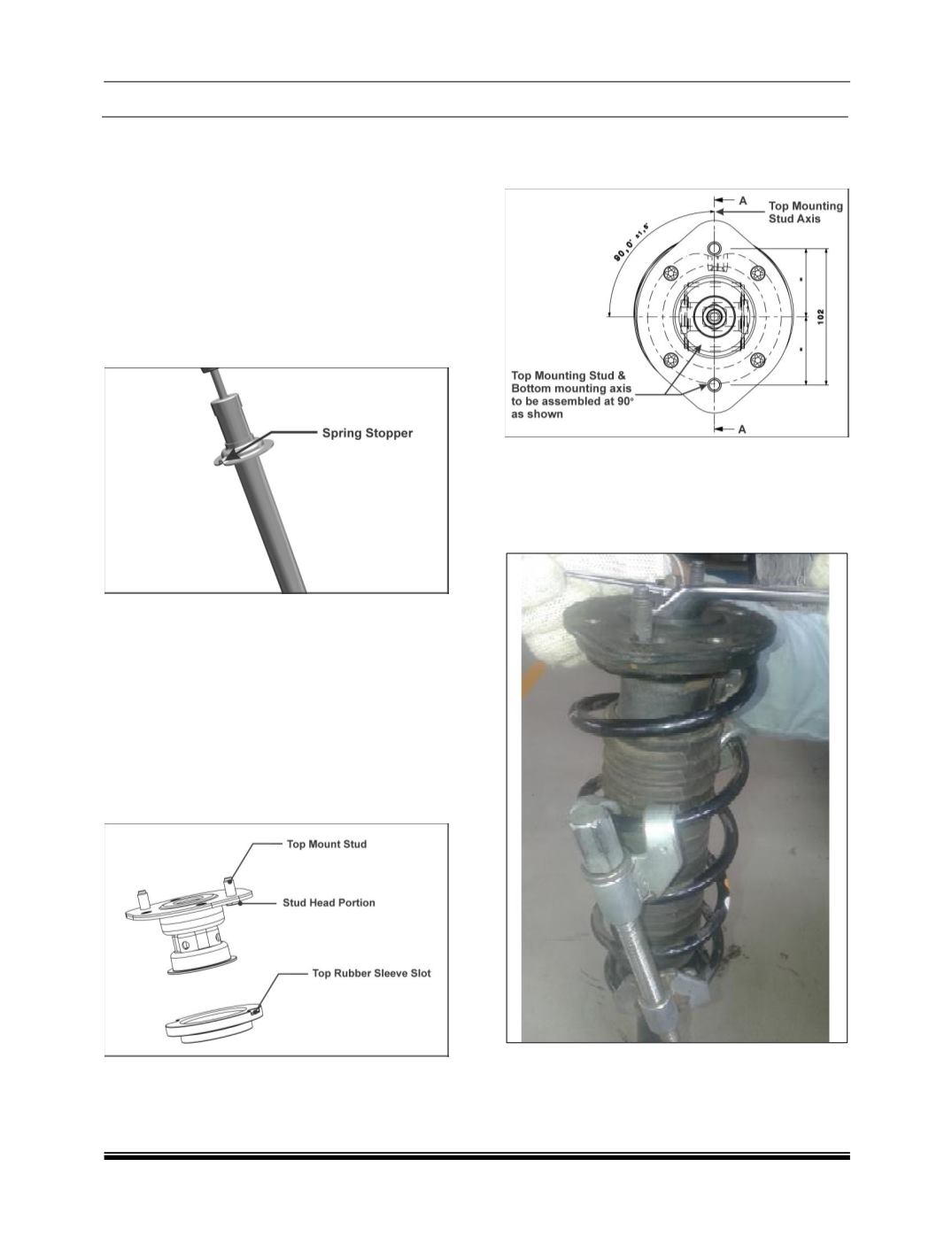

1. Compress the spring with spring compression

tool part No.2702 5890 3202 to reduce length

as done during disassembly as shown in Fig.

61.

2. Insert the compressed spring on the damper

(Ensure that the spring end is resting with

stopper provided on spring seat lower).

FIG. 62

3. Insert Bump stopper on piston rod.

4. Assemble dust cover in the spring. (Ensure dust

cover is properly located in spring).

5. Insert special fastener on piston rod and tighten

it to 2 kg.m torque to ensure the location.

6. Assemble top mount with rubber sleeve

separately before placing on special fastener.

(Ensure top mount M10 bolt heads should be

placed in the rubber sleeve slots).

FIG. 63

7. Ensure the orientation of bottom eye axis with

top mount stud axis to 90 deg as shown in

Fig.64.

FIG. 64

8. Fit Nyloc Flange nut and tighten to 6-7 Kg.m

torque. Hold the piston rod by spanner/tool

(A/F: 6 mm) to stop piston rod rotation during

tightening of nut. Fig.65.

FIG. 65

9. Remove spring compression tool carefully.