1.05L REVOTORQ ENGINE

103

5. Loosen and remove the 6 mounting nuts.

6. Lift the in-tank pump carefully out

NOTE

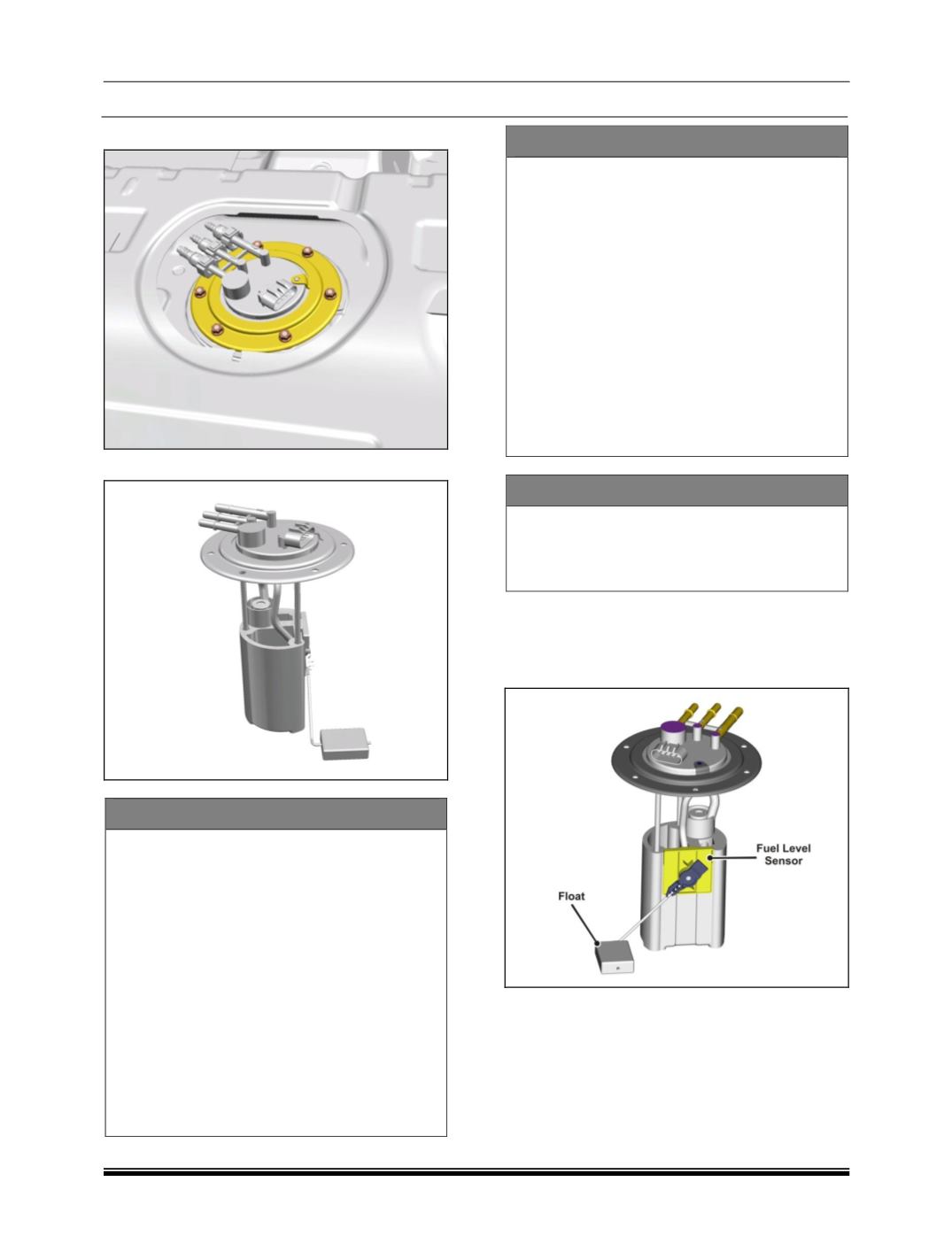

The fuel module shall consist of level

sensor, sealing ring and locking ring.

The material of the FSU seal shall be

HNBR as per SS:5565

Pump should have a flexibility in orientation

atleast for two positions.

Electrical cables and hoses connecting

pumps and flange should not be protrude

outside the diameter.

The float orientation to be decided by party

for better performance.

Be free from flash, Flaw, Rust and Concave

on joining and sealing surface.

Be free from foreign body in fuel passage.

ASSEMBLY

Don't hold the fuel pump unit by tubes,

wires, fuel level sensor unit.

Remove the protection cap only before

assembly of the hydraulic connector.

The fuel pump unit only has to be fixed at

the outer diameter of the tank flange during

assembly into fuel tank.

During transport of the tank with assembled

fuel pump unit. It is absolutely necessary to

protect the tubes with protective caps

against dirt, particles etc.

Return line of vehicle has to be clean.

Hydraulic protection cap : Protection only

against dust and splash water

CONDITION OF USE

Minimum tank filling height for start of the

engine after first filling equal to 25 mm from

bottom of reservoir. (Only valid for

horizontal tank bottom)

E. Fuel Level Sensor :

Removal :

1. Remove the tank unit.

2. Disconnect the connector.

3. Remove the fuel level sensor by releasing the

snaps.

Fuel Level Sensor Specification :

Vehicle operating voltage : 12V DC with -ve

ground

Operating voltage : 8V to 16V