1.05L REVOTORQ ENGINE

128

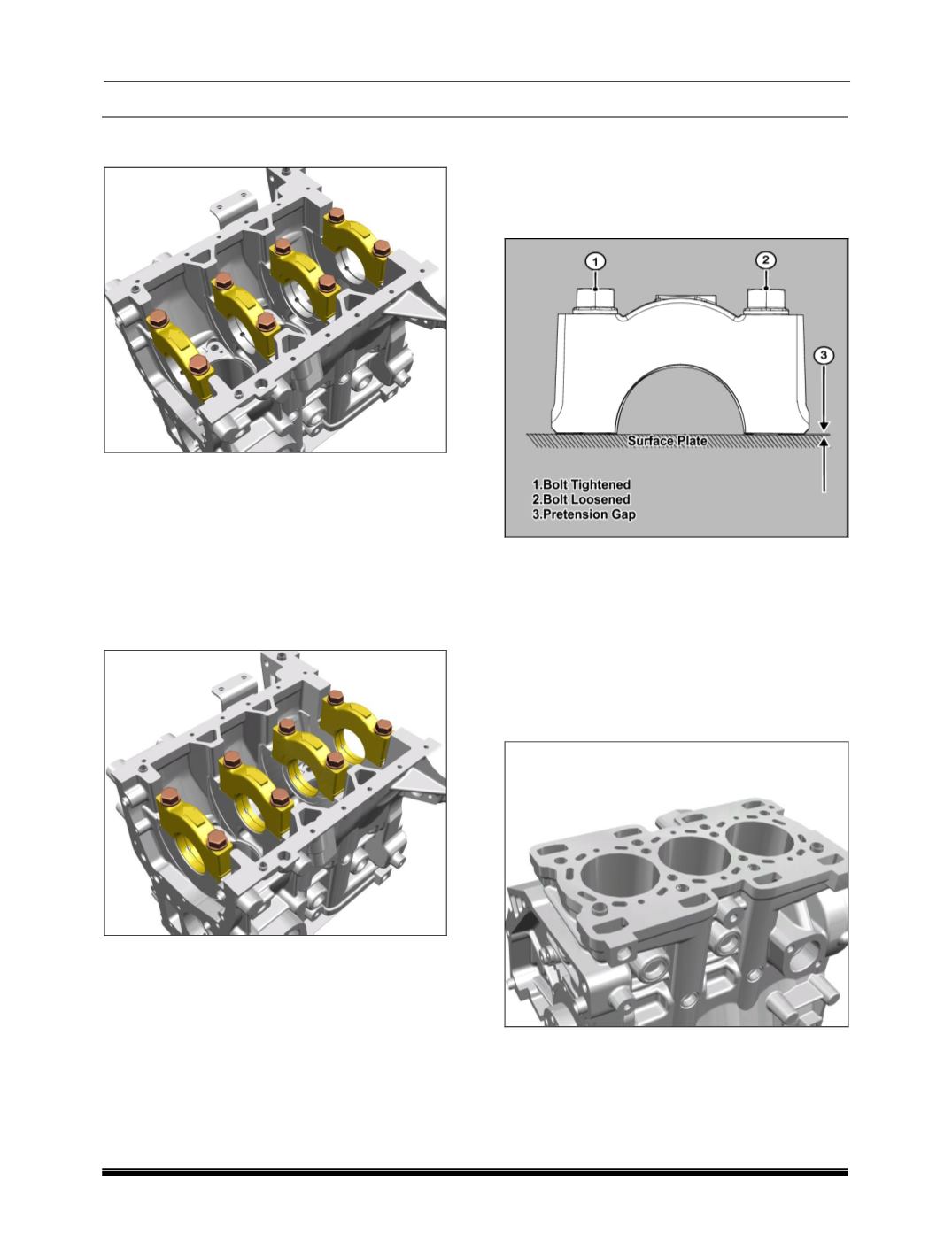

5. Check crank case main bearing parent bore

dimensions.

6. Install new pairs of main bearing shells

according to size of crank shaft main bearing

journal diameter, making sure that securing

lugs of bearing shells are properly seated in

grooves of crank case and main bearing caps.

7.

Install main bearing caps with bearing shells in

their respective position on crank case.

Tighten main bearing cap mounting bolts in

specified sequence to specified torque.

Measure main bearing bore.

8. If main bearing parent bore dimensions are

within specified limits, proper main bearing

bore dimension is automatically achieved.

9. Loosen one of the main bearing cap mounting

bolts. Now using a feeler gauge measure the

pretension gap of main bearing shell. As the

main bearing caps are guided, the

measurement has to be done on a flat surface

and not on cylinder block.

10.Main bearing shells are precision finished and

should not be bored or scrapped.

11.Select new pair of thrust washer according to

crank shaft 4th main journal width.

12.Pretension Gap: 0.06 to 0.09mm.

Cylinder Bores :

1. Clean cylinder bores thoroughly

2. Check cylinder bore dimension, taper and

ovality.

3. If taper and ovality is found to exceed specified

limit or bore is excessively worn out then

replace the block.

4. Record the readings in Engine inspection

sheet given in this manual.