1.05L REVOTORQ ENGINE

127

Note :

It is essential to recheck crank shaft for cracks

and balance after grinding.

18.Apply grease to all machined surfaces, if crank

shaft is to be stored. Crank shaft must always

be stored in vertical position.

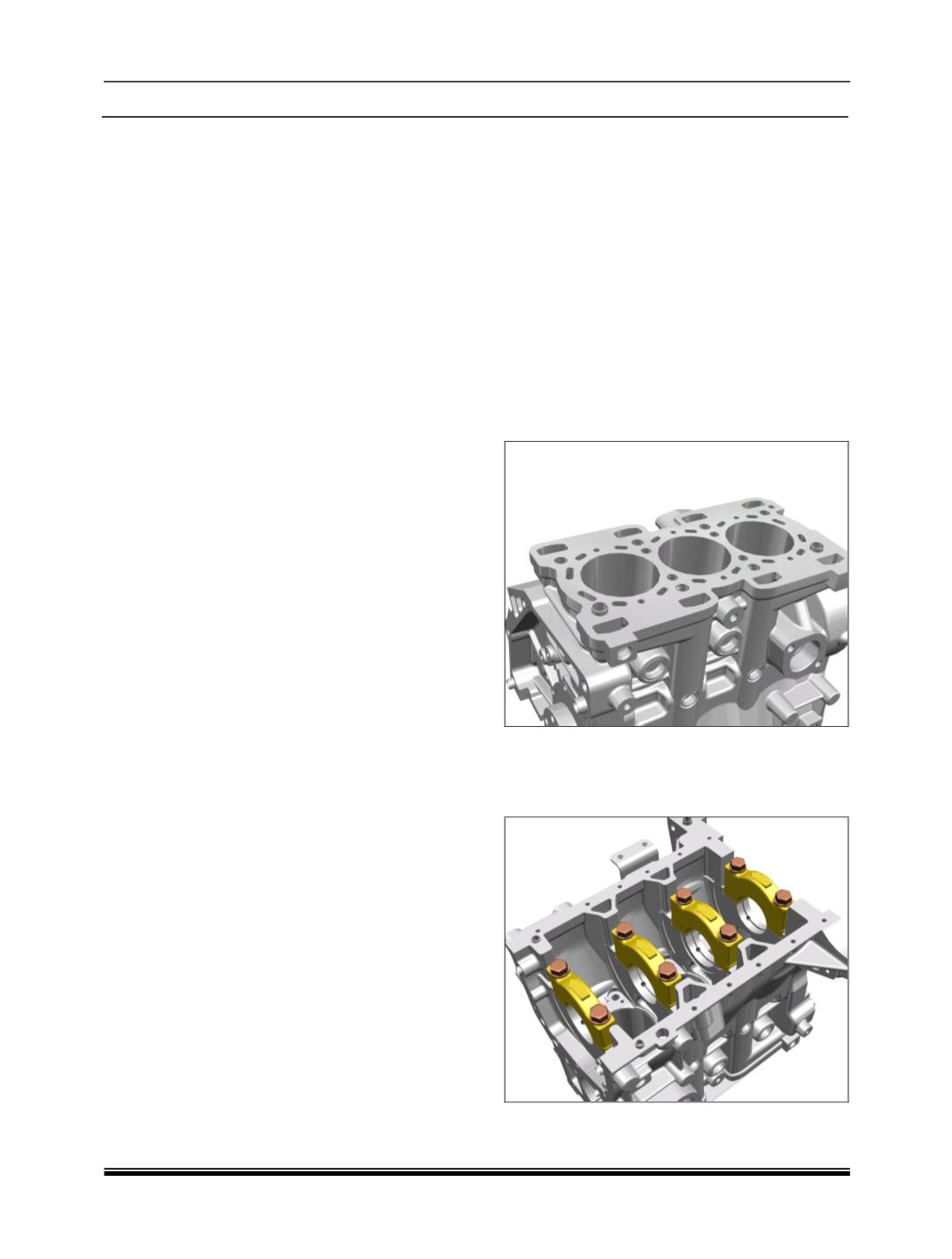

19.Thoroughly clean main bearing caps and

corresponding

machined

surfaces

of

crankcase.

20.Install main bearing caps without bearing

shells in their respective positions on

crankcase.

Note :

Ensure that the serial numbers on crank case and

main bearing caps are matching. Also caps are in

order and notches forbearing shells are on same

side.

Cylinder Block :

1. Check cylinder block for cracks by pressure

testing method. Clean cylinder bores, bearing

surfaces, oil passages in crank case

thoroughly. Check water jackets for leakages

by blowing air at a pressure of 5 bar & then

dipping the cylinder block in the hot water

(Temp of water 70° to 80°C)

Note :

The block with any leakages / cracks should be

discarded.

2. Check crankcase mating surface with cylinder

head for unevenness with the help of straight

edge and feeler gauge. If necessary grind this

surface just too clear unevenness. Measure

across the length and also across the breath.

3. Ensure that the minimum height of crank case

is not less than the specified minimum height.

4. Tighten main bearing cap mounting bolts to

specified torque