1.05L REVOTORQ ENGINE

121

7.

Clean valve seat insert and its bore in cylinder

head thoroughly.

F. Just Before Installation :

1.

Place valve seat insert in mixture of Methanol

and dry ice for about 20-30 minutes to bring

temperature down to -150ºC.

2.

Heat cylinder head to approximately 80ºC in

hot water bath.

3.

Install valve seat insert in cylinder head bore

quickly by light hammering.

4.

Machine valve seat in cylinder head.

G. Cam Shaft :

1.

Check cam shaft run out at 2nd journal by

supporting it on V-block at 1st and 3rd journal.

2.

Check cam shaft journal dimensions. Record

the readings.

3.

Carry out visual inspection of cam shaft for:

•

Overheating of journals, this is indicated by

bluish/ brown colour.

•

Deep scoring marks on journals and cam

lobes

•

Cracks, which should be checked on a

magnetic crack detector.

4.

Check hardness of cam shaft journals and cam

lobes, it should be 47 HRC.

H. Hydraulic Lash Adjuster :

Hydraulic Lash Adjuster supports the pivot end of

the rocker arm while automatically controlling the

rocker arm position to keep it in contact with the

camshafts and valve.

The range of the hydraulic lash adjuster

accommodates engine build tolerances; hence no

adjustment is required during engine assembly. It

also compensates for variation that occurs during

the life of the engine.

For information on HLA and inspection refer

Lubrication section.

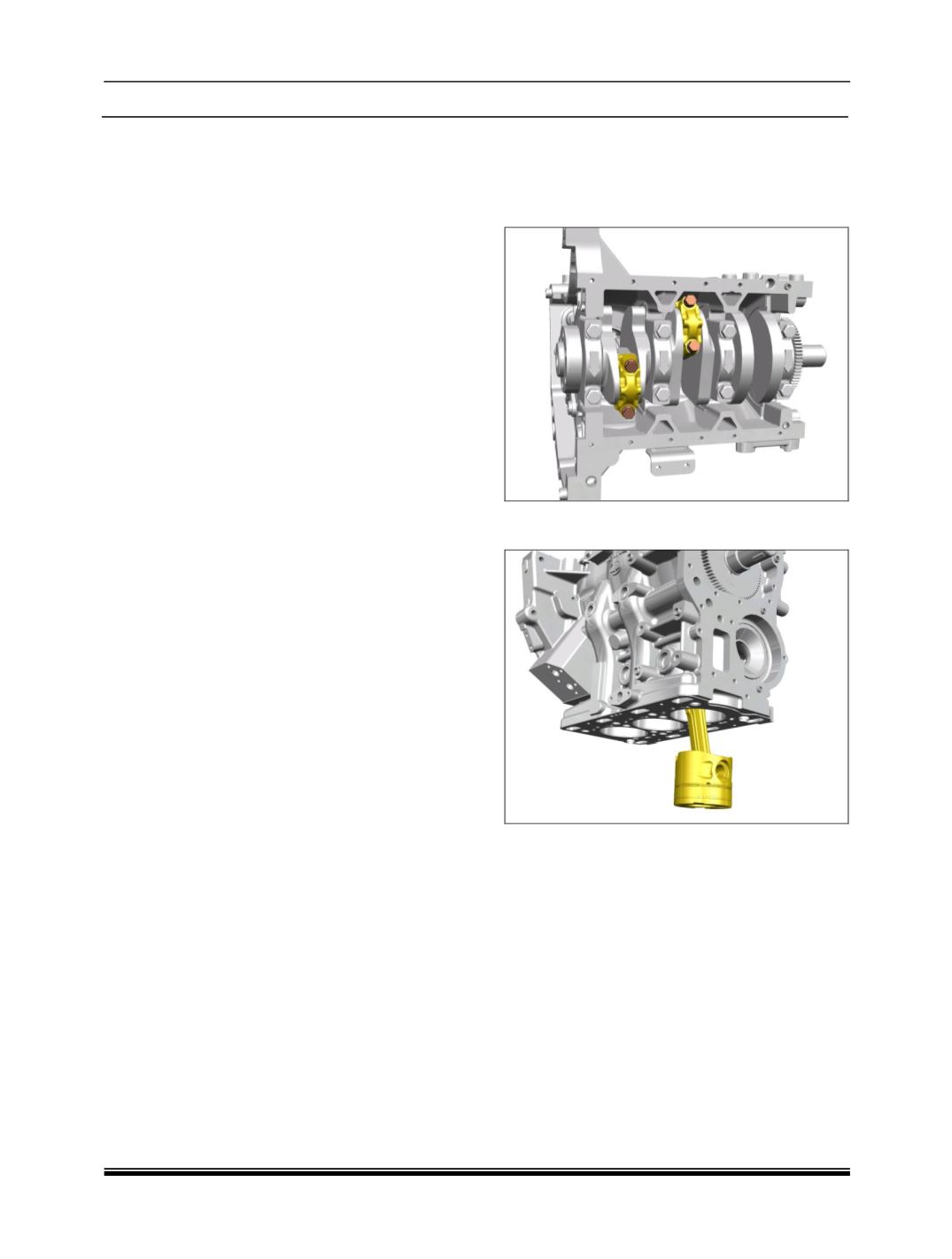

viii. REMOVAL OF CYLINDER BLOCK SUB-

ASSEMBLIES :

1.

Turn the Crankshaft and bring a pair of pistons

near BDC position. Unscrew connecting rod

bearing cap mounting nuts.

2.

Push the piston assemblies out of cylinders

using wooden handle of mallet.

3.

Remove connecting rod bearing shells and

duly mark them with paint on their back in case

these are to be reused.

4.

Verify serial numbers on connecting rod

bearing caps and connecting rods.

5.

Remove remaining pistons in a similar manner

Note:

It is essential to assemble connecting rod bearing

caps to their respective connecting rods only.