1.05L REVOTORQ ENGINE

86

The following components must not, under any

circumstances, be removed from the pump inlet

hydraulic connector; Hp outlet hydraulic con-

nector and fuel return connector.

Do not carry the pump using drive shaft.

Injector electronics are polarized. In case of in-

tervention or wiring harness, do not invert wires.

It is destructive for the piezo components.

Don’t drive the injectors if their body is not con-

nected to the battery ground. Injector body has

to be in contact with cylinder head.

Do not try to drive the injectors with anything but

the ECU.

Do not make a short circuit between grounds of

injectors. Injectors will remain open: broken en-

gine.

Do’s

Monitor battery voltage continuously – recharge

battery if voltage drops below 10 Volts

Drain water from Sedimenter / filter at regular

intervals

Fix the rubber cover to the ECU to prevent dust /

moisture entry inside ECU.

EMS W/H to be properly routed as specified us-

ing clamps / clips and brackets.

Do check for any faults /malfunctioning in the

system using diagnostics tool before cranking

the engine

(after any repair).

Do fix ECU connector branch properly while

transporting engine.

If engine does not start check the respective

fuses related to 1.05 CRAIL components.

When Injectors are replaced/Changed Injector IC

values must be loaded correctly as per cylinder

order.

Plug the port of Common rail system compo-

nents whenever any pipe connections are

removed.

If the fuel tank is dry

(no diesel)

fill diesel and

use priming pump to suck the diesel till fuel filter.

Tighten the mounting nuts / cap nuts etc. only to

the specified torque values.

Always remove the Injectors before dismantling

the cylinder head. This is to avoid damage to the

injector nozzle tips which protrude out of cylinder

head. In case of HP pump removal handle the

pump with proper care to avoid any damage to

inlet pipe, venturi and connectors.

Always use specified tightening torques, during

assembling of 1.05 CRAIL components.

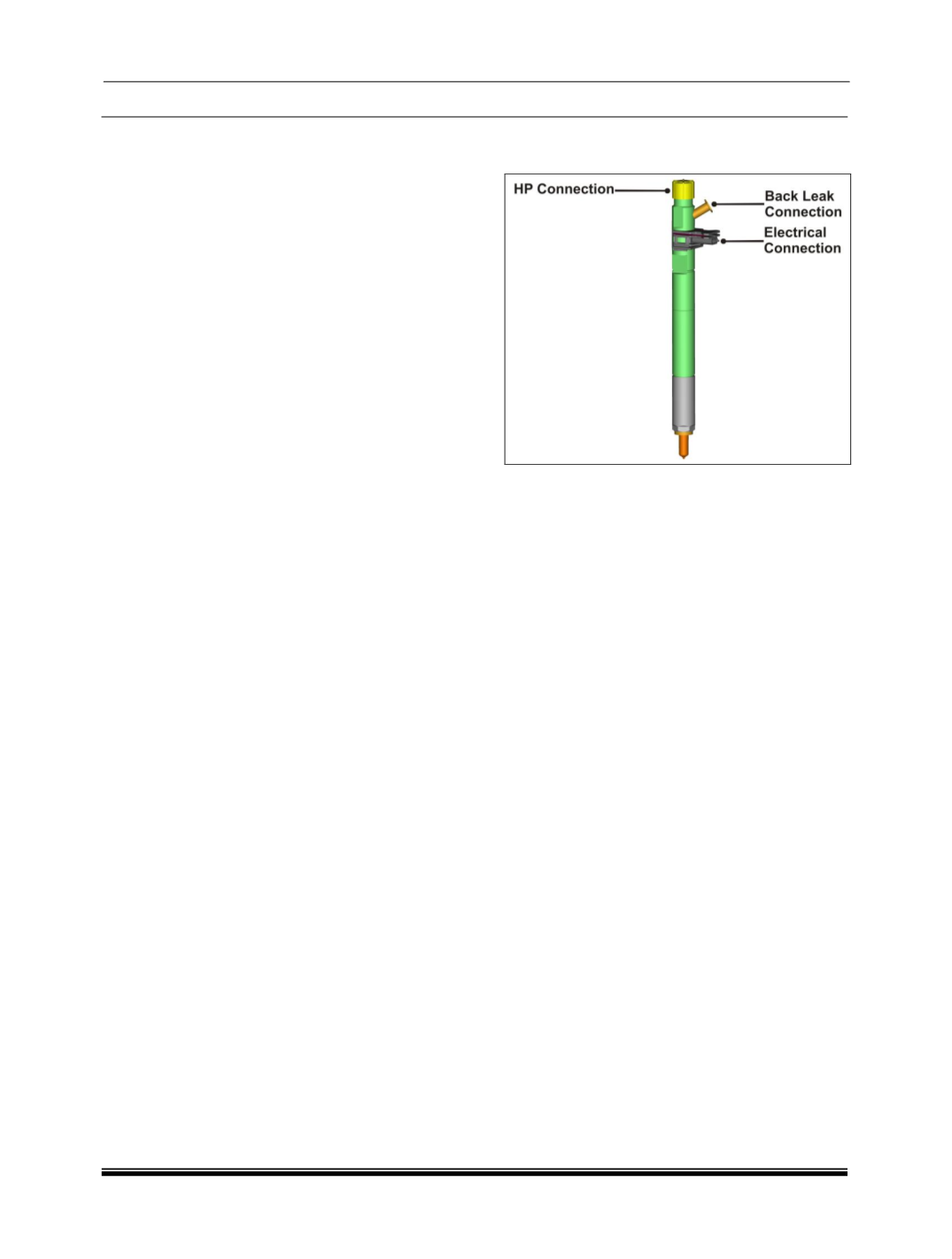

Components :

A. Injector :

The injector used in this engine is a piezo

injector. This is controlled by the EMS ECU. The

timing of injection and quantity is controlled by the

EMS ECU. It operates at a pressure of 1800 bar. It

makes multiple injections.

The piezo actuator is an electrically ener-

gized device that acts similar to a solenoid but is

much more precise. A piezo actuator is a composi-

tion of piezo discs, that when electrically energized,

cause the discs to deform resulting in an expansion.

This expansion results in a longitudinal motion thus

controlling the injector. When energized, the piezo

actuator pushes downward against the valve piston.

The piezo actuator is returned to its non energized

state via the ECU switching the polarity of the elec-

trical feed to the injector.