ENGINE 1.3L QUADRAJET (90PS)

49

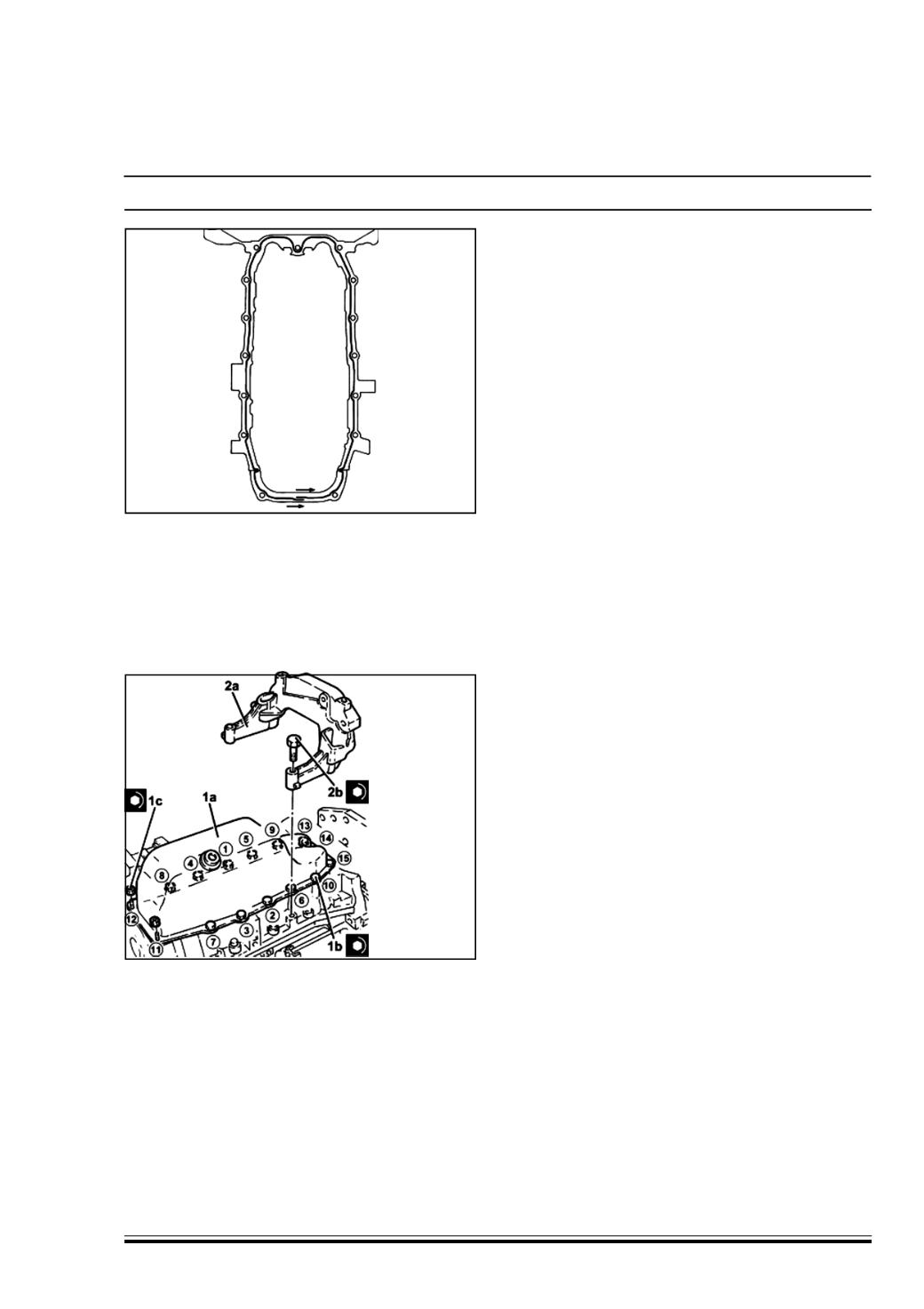

46.Apply a strip of grey silicone sealant to the contact

surfaces between the crankcase sump and lower

engine block as shown in the diagram in the figure.

NOTE :

The sealant strip must be continuous and unbroken.

The sealant strip diameter must be 3.0 - 4.0 mm.

48.Place the bracket (2a) in its housing and secure it

by tightening the M8 bolts (2b) to a torque of 2.7 ~

3.3 Kg-m.

49.Rotate the engine through 180° on the overhaul

stand.

50.Place the engine oil dipstick pipe back in its

housing and fasten it with the bolt.

51.Close the oil vapour pipe retaining clip.

52.Place the intermediate driveshaft mount in position

and secure it tightening the M8 bolts to a torque

of 2.0 ~ 2.4 Kg-m.

53.Remove the

tool 287158900651 (Hose).

54.Position the crankcase pulley support flange in its

housing & secure it with the left threaded bolt

without tightening it to the recommended torque.

55.Place the water pump, complete with gasket in

position, and then tighten the M10 bolts to a 0.8 ~

1.0 Kg-m torque.

56.Position the crankshaft pulley in its housing and

secure it without tightening the bolts

57.Position the engine components single belt moving

tensioner in its housing and secure it tightening

the M10 bolt to a torque of 4.5 ~ 5.5 Kg-m .

58.Position the engine components single belt moving

tensioner in its housing and secure it tightening

the M10 bolt to torque of 4.5 ~ 5.5 kg-m.

59.Position the auxiliary drive belt fixed tensioner in

its housing and secure it tightening the M8 bolt to

a torque of 2.2 ~ 2.7 Kg-m .

60.Adjust the mobile tensioner with a wrench and fit

the auxiliary drive belt.

61.Place the timing side rigid engine support in its

housing with the engine lift bracket and secure it

tightening the M10 bolts to a torque of 5.7 ~ 6.3

kg-m.

62.Place the turbocharger unit complete with catalytic

converter back in its housing and secure it by

tightening the M8 nuts to a torque of 2.2 ~ 2.7 Kg-

m .

63.Refit the exhaust manifold heat shield with the

engine lift bracket and secure with the nut and bolts.

64.Position the pipe carrying engine oil to the

turbocharger in its housing and secure it tightening

M10 connectors to a torque of 1.3 ~ 1.6 Kg-m.

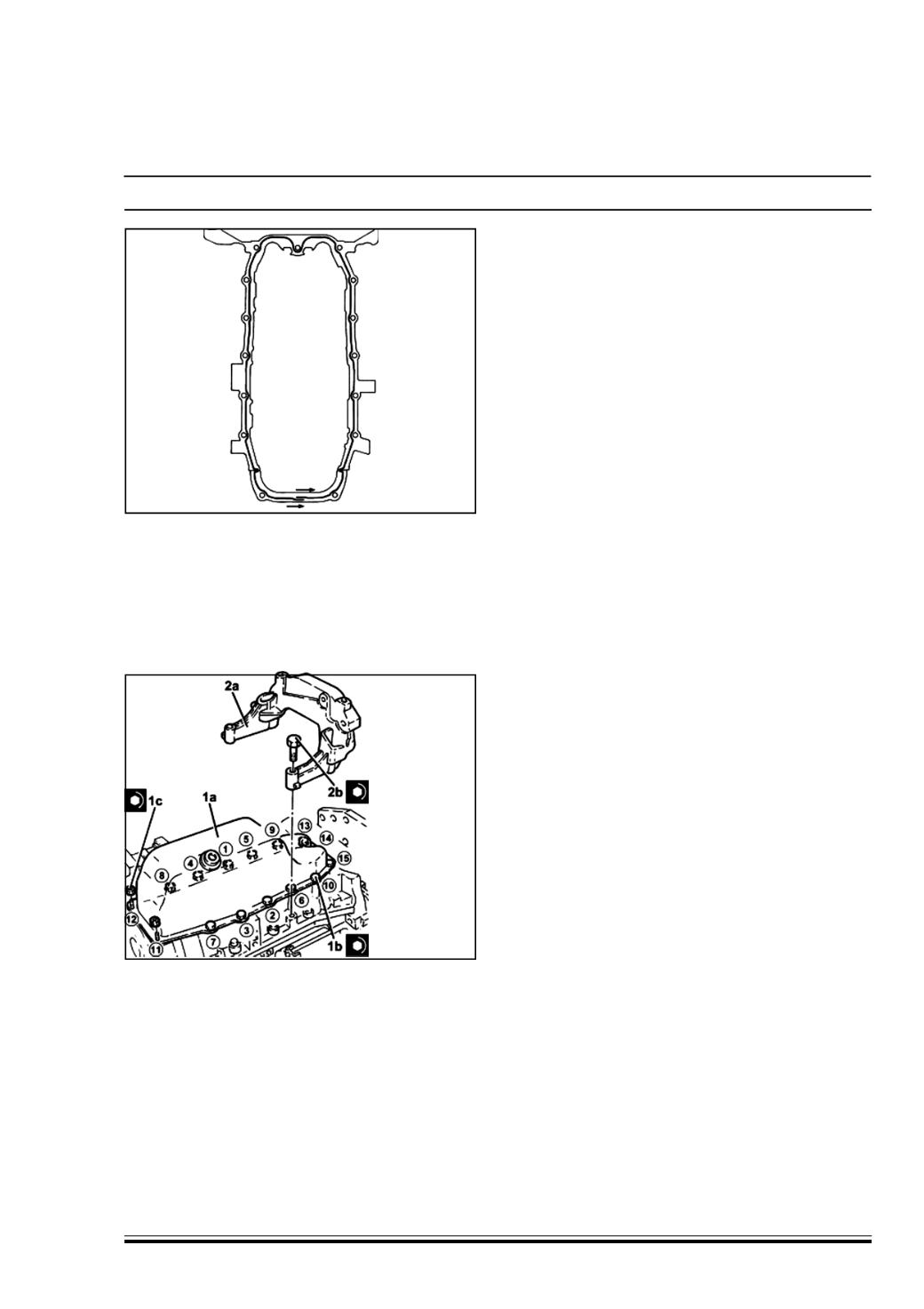

47.Position the crankcase sump (1a) in its housing

and secure it tightening theM6 bolts (1b) to a torque

of 0.8 ~ 1.0 Kg-m and the M6 nuts (1c) to a torque

of 0.8 ~ 1.0 Kg-m.

NOTE :

Follow the order shown in the figure for each tightening

sequence. The tightening to 0.8 - 1.0 Kg-m is

performed in two stages: pre tightening to 0.4 Kg-m

followed by an additional tightening of 0.8 - 1.0 Kg-m.