ENGINE 1.3L QUADRAJET (90PS)

48

31. Connect the fuel return pipe to the single fuel

manifold and tighten the band.

32. Fit new pipes from the fuel manifold to the injectors

and secure with connectors without tightening.

33. Tighten the connectors for the pipes from the fuel

manifold to the injector side injectors to a torque

of 2.3 ~ 2.5 Kg-m using an appropriate

commercial wrench.

34. Tighten the connectors for the pipes from the fuel

manifold to the fuel manifold side injectors to a

torque of 2.6 ~ 2.9 Kg-m using an appropriate

commercial wrench.

NOTE

Q

Clean the threaded pipe seats on the manifold

and injectors with heptane.

35. Place a new pipe from the pressure pump to the

single fuel manifold in its housing and secure it

using the connectors without tightening them.

36. Tighten the M12 connector for the pipe from the

pressure pump to the single fuel manifold, pump

side, to a torque of 2.3 ~ 2.5 Kg-m using a

spanner.

37. Tighten the M14 connector for the pipe from the

pressure pump to the single fuel manifold, fuel

manifold side, to a torque of 2.6 ~ 2.9 Kg-m using

a spanner.

38. Connect the fuel outlet pipe from the injectors,

injector side and push in until the clips click into

place.

39. Place the camshaft cover gasket back in its

housing.

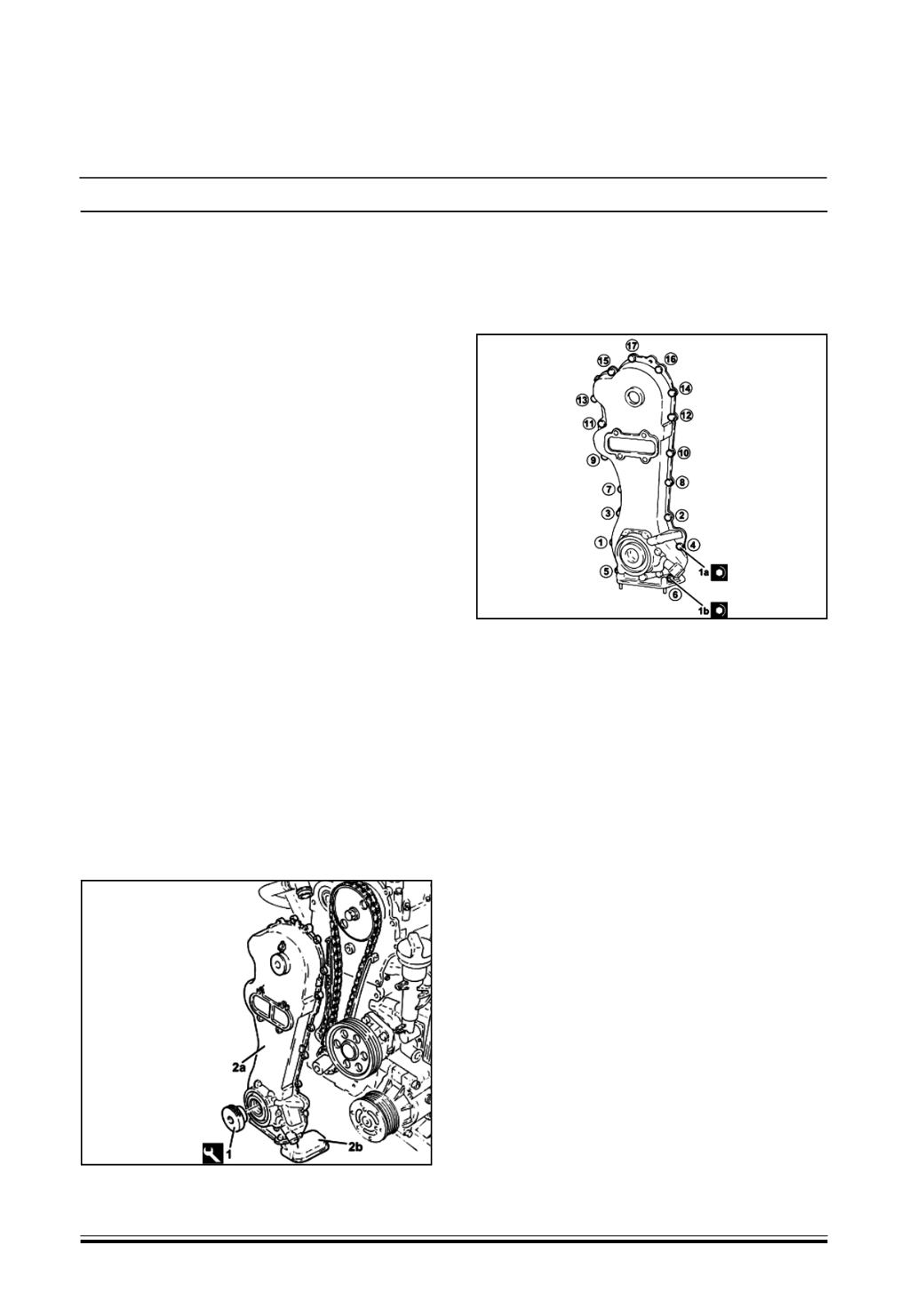

40. Fit the tool (1) 287158900651 (Hose) to the

timing cover.

41. Refit the timing cover (2a) complete with engine

oil suction device (2b) and engine oil pump.

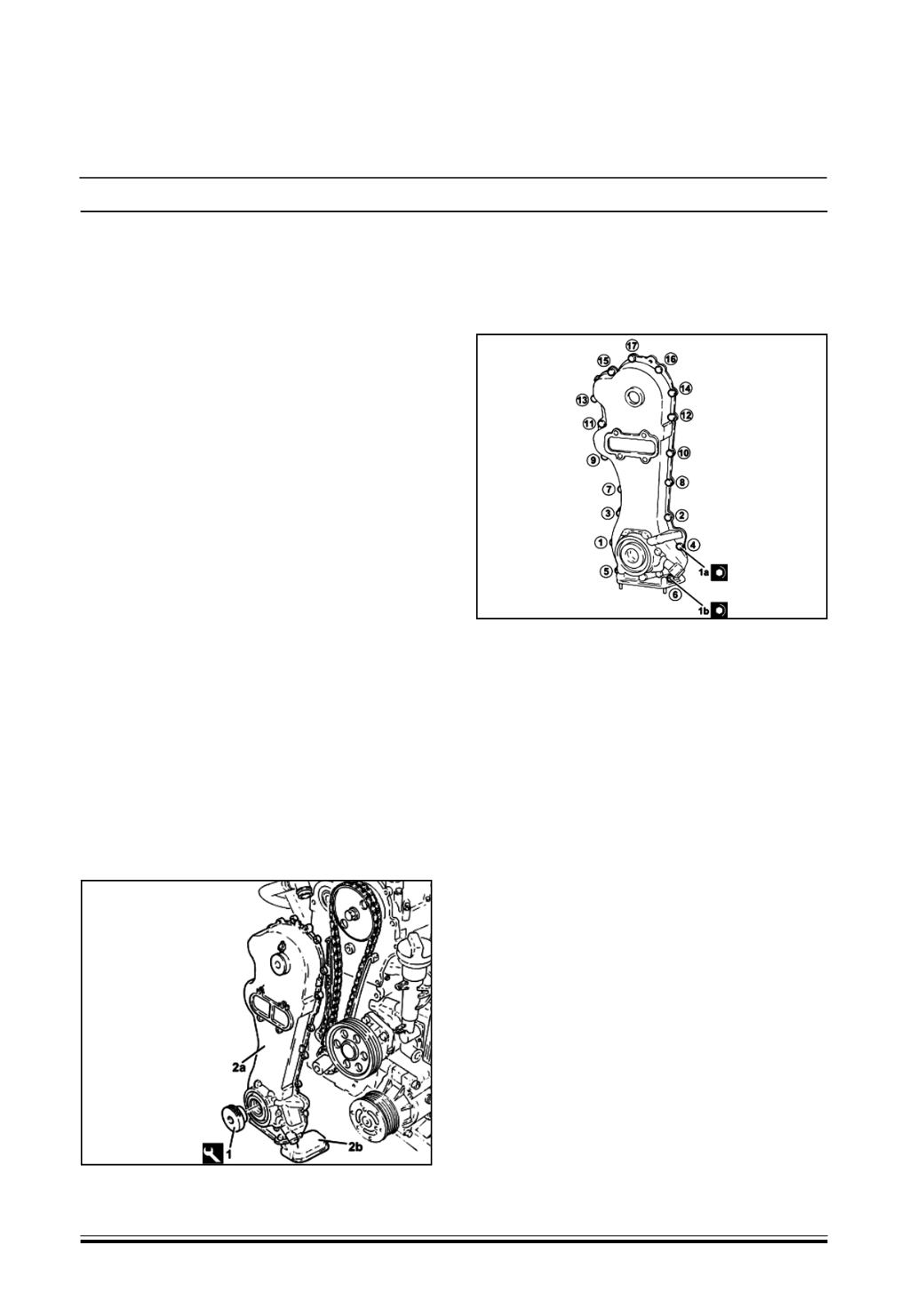

42. Tighten the M6 bolts (1a) to a torque of 0.8 ~ 1.0

Kg-m and the M6 nuts (1b) to a torque of 0.8 ~

1.0 Kg-msecuring the timing cover to the specified

torque.

NOTE :

Follow the order shown in the diagram for each

tightening sequence. The tightening to 0.8 - 1.0 Kg-m

is performed in two stages: a tightening stage to 0.4

Kg-m followed by an additional tightening of 0.8 - 1.0

Kg-m .

43.Connect the engine oil vapour recirculation pipe

fitting to the timing cover and tighten the bolts.

NOTE :

Ensure the O-ring is present and correctly positioned.

44.Rotate the engine through 180° on the overhaul

stand.

45.Place the crankcase oil sump partition back in its

housing and secure it using the bolts.