ENGINE 1.3L QUADRAJET (90PS)

43

C. CYLIDER HEAD BLOCK ASSEMBLY -

REFITTING

1. Refit the air chamber complete with gasket and

pressure relief sensor back in its housing and

secure it tightening the M8 bolts to the

recommended torque of 2.3 ~ 2.8 Kg-m .

2. Replace the engine oil vapour separator with engine

oil vapour recirculation pipe in its seat and secure

with bolts.

3. Fasten the engine oil vapour recirculation pipe to

the retaining collars on the air capacity chamber.

4. Place the exhaust gas/water heat exchanger for

the E.G.R. system complete with gasket back in

its housing and secure it by tightening the M8 bolts

to the specified torque of 2.3 ~ 2.8 Kg-m .

5. Replace the engine oil pressurewarning light switch

(M14) in its housing and tighten it to the

recommended torque of 2.9 ~ 3.5 kg-m.

6. Place the thermostat in its housing with the O-ring

and secure it by tightening the M8 bolts to the

recommended torque of 2.2 ~ 2.7 Kg-m .

7. Replace the coolant delivery sleeve from the

thermostat to the coolant/exhaust gas heat

exchanger for the EGR system and secure with

the relevant collars.

NOTE :

Before fitting the locating bushes, check

that the height is 13 mm.

8. Refit the camshaft housing locating bushes in their

seats in the cylinder head.

9. Place the hydraulic tappets in their housings.

NOTE

Q

Position the hydraulic tappets with the oil channel

hole turned toward the outside of the cylinder head:

this position brings the hole into communication with

the oil duct on the lower cylinder head.

10. Place the valve rockers in their housings.

11. Remove the cylinder head from the support tool

287158900624 (Mount).

12. Refit the glow plugs (M8) and tighten them to the

recommended torque of 0.9 ~ 1.1 Kg-m .

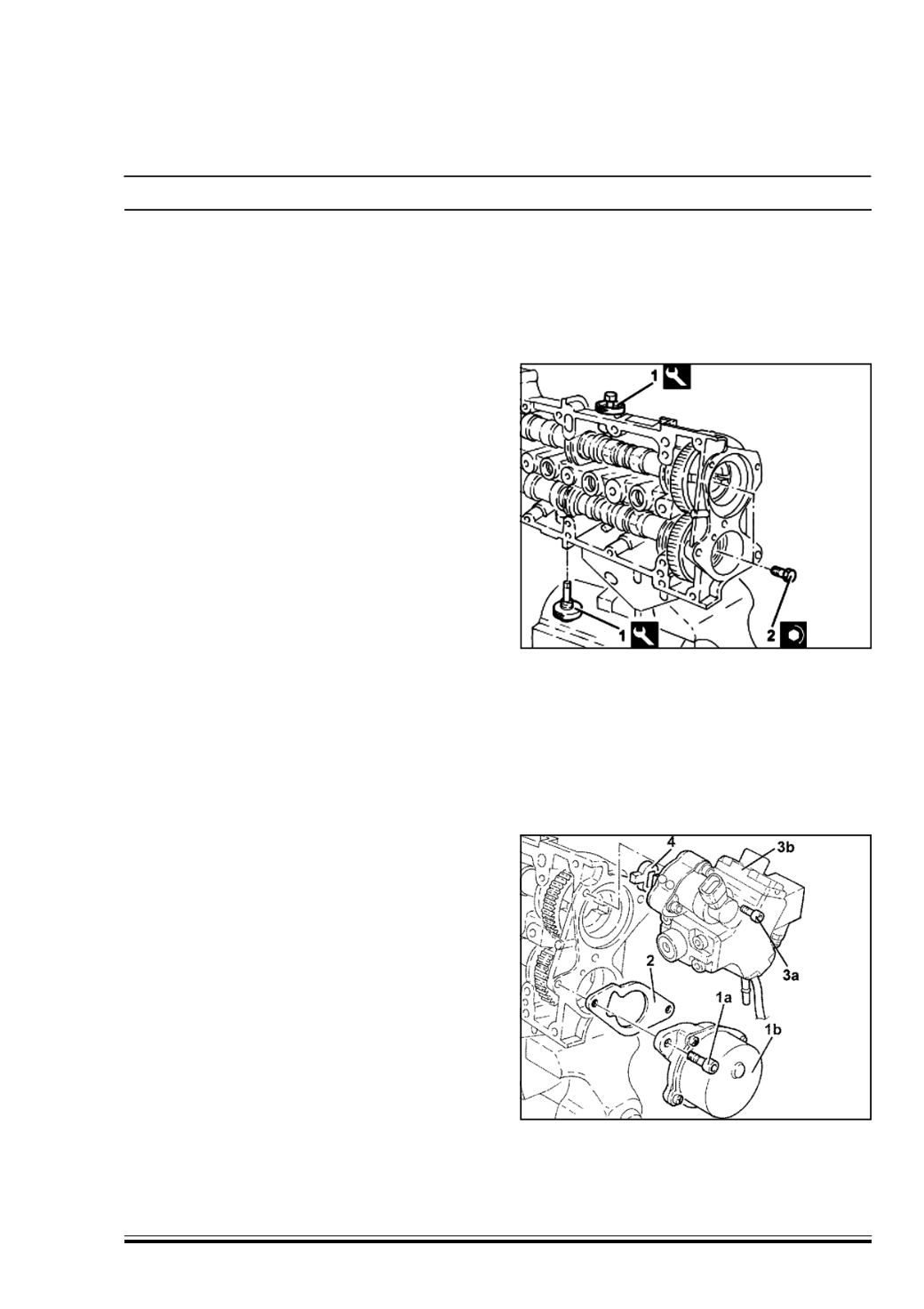

13. Place the exhaust manifold gasket in its housing.

14. Place the air conditioning compressor mounting

in its housing and secure it by tightening the M8

nuts (do not reuse the nuts) to the recommended

torque of 1.4 ~ 1.6 Kg-m+ 30° +/- 3°.

15. Position the cylinder head extension in the vice

using the tool 287158900624 (Mount).

16. Place the camshafts in their housings.

17. Place the camshaft caps in their housings and

secure them without tightening the bolts.

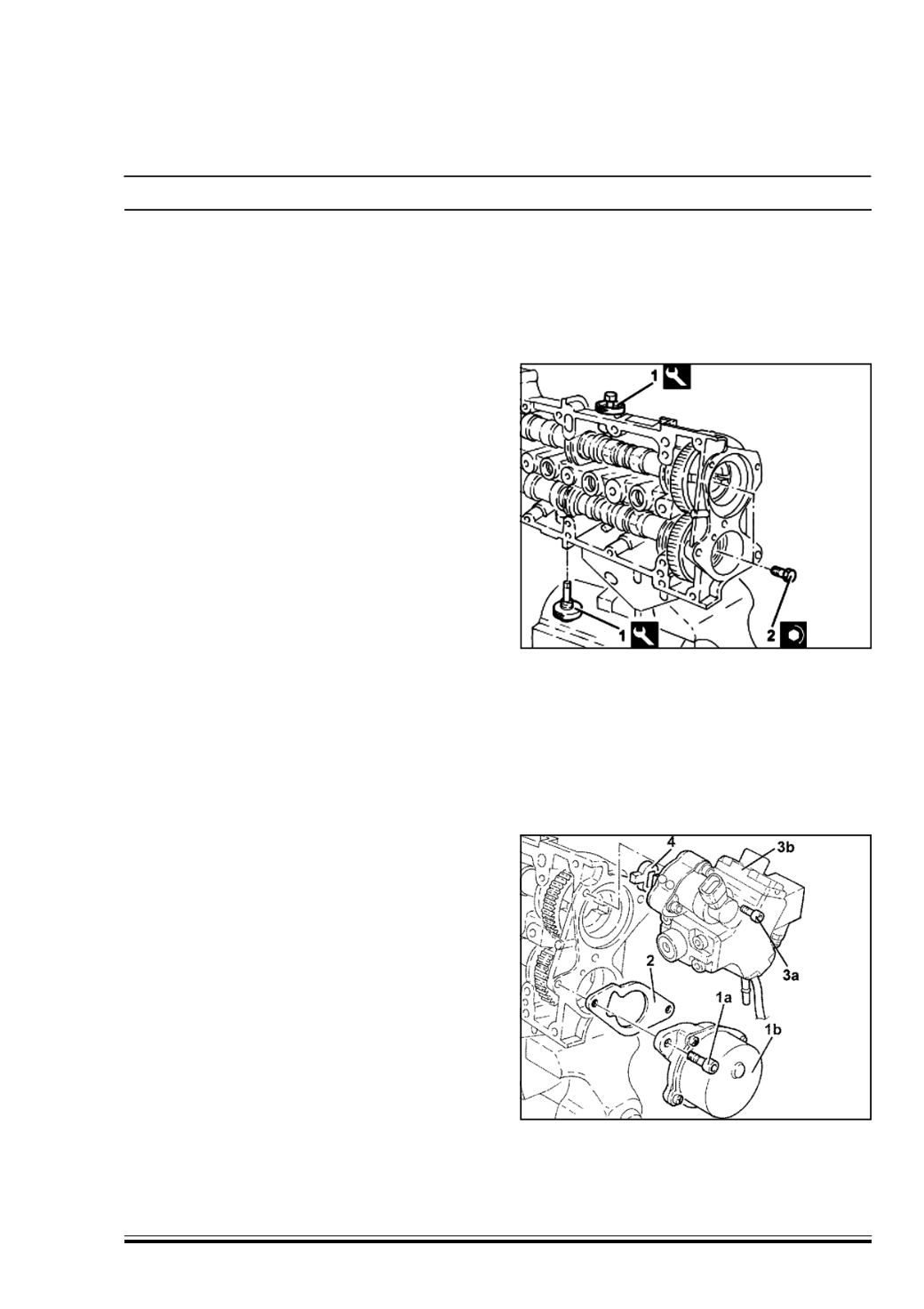

18. Fit the camshaft timing tools 287158900655

(Template)

19. Tighten the camshaft gear fixing M12 bolts to the

recommended torque of 13.5 ~ 16.5Kg-m .

20. Place the cam angle sensor back in its housing

and secure it tightening the M6 bolt to the

recommended torque of 0.64 ~ 0.96 Kg-m .