ENGINE 1.3L QUADRAJET (90PS)

59

3

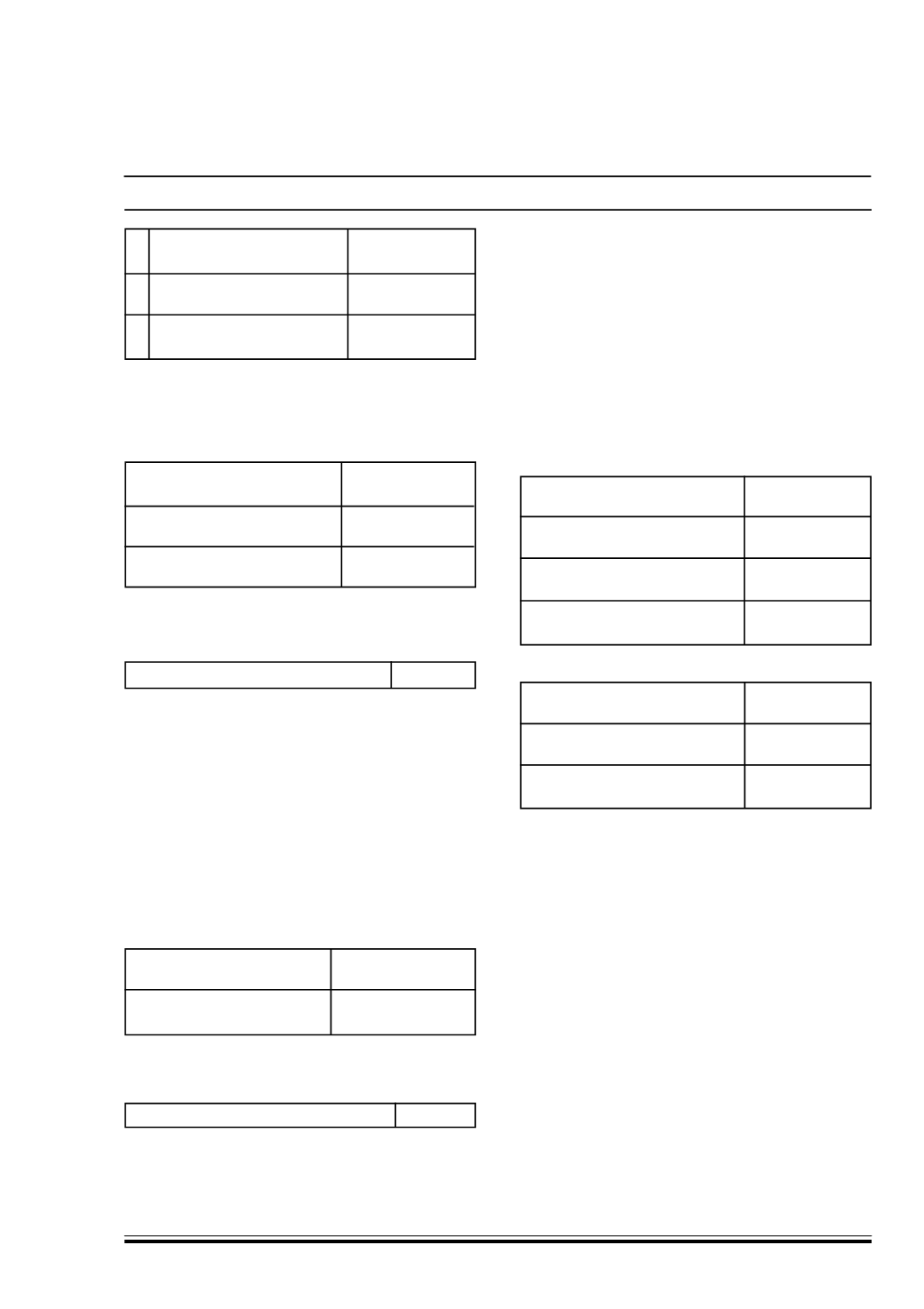

Main journal seat diameter - 54.710 ~ 54.714

Category A (mm)

3 Main journal seat diameter - 54.714 ~ 54.718

Category B (mm)

3 Main journal seat diameter - 54.718 ~ 54.722

Category C (mm)

16.Check that there are no deposits or blockages in

the crankshaft lubrication ducts.

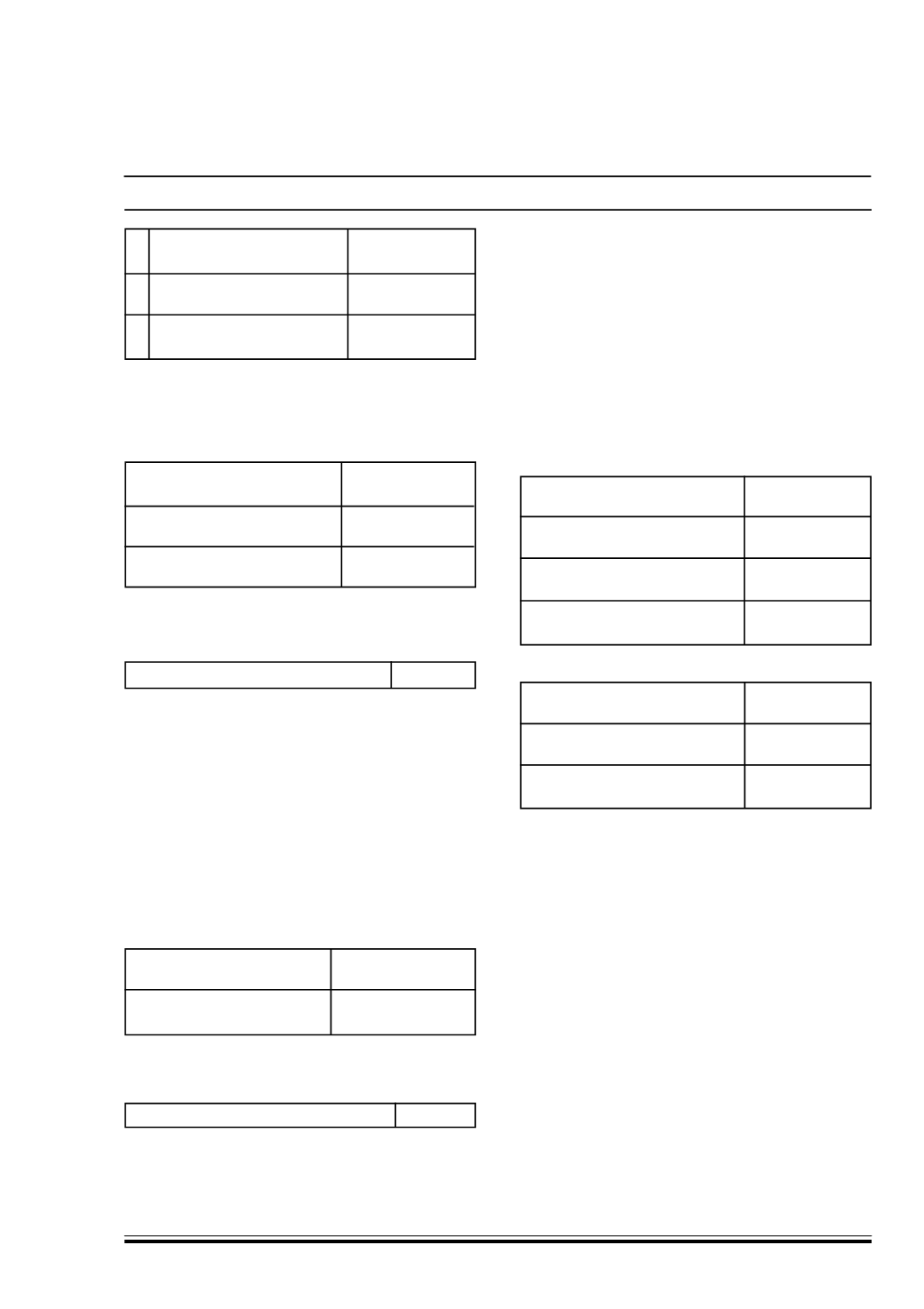

17 Check that the diameter of the main journals

corresponds to the recommended figures.

Main journal diameter -

50.994 ~ 51.000

CategoryA (mm)

Main journal diameter -

50.988 ~ 50.994

Category B (mm)

Main journal diameter -

50.982 ~ 50.988

Category C (mm)

18.If the diameter of the main journals is not within

the specified limits, they should be reground to

the recommended undersize of 0.127mm.

Main journal diameter undersize (mm) 0.127

NOTE :

The crankpin undersize should not be higher than the

specified values as it will adversely affect the struc-

tural resistance of the crankshaft (following contact

between the tool and rolled connectors). As far as the

above is concerned, if the regrinding requires an un-

dersize greater than 0.127 mm, then the crankshaft

must be replaced with a new one. For an undersize of

more than 0.127mm, only the half bearings should

never be replaced, even if it is available for purchase.

19 Check that the diameter of the crankpins

corresponds to the recommended figures.

Crankpin diameter -

42.591 ~ 42.600

CategoryA (mm)

Crankpin diameter -

42.582 ~ 42.591

Category B (mm)

20.If the diameter of the crankpins is not correct, they

should be reground to the recommended undersize

of 0.127 mm.

Crankpin diameter undersize (mm)

0.127

NOTE

Crankpin undersizes higher than the value men-

tioned will adversely affect the structural resistance

of the crankshaft (following contact between the tool

and rolled connectors). As ar as the above is con-

cerned, if the regrinding requires undersizes greater

than 0.127 mm, then the crankshaft must be replaced

and a new one ordered from the Parts Dept. The half-

bearings used for undersizes of more than 0.127 mm

should not be ordered from the Parts Dept. (even if

the number is still quoted)

21.Check the crankshaft and connecting rod bearings,

having inmind that no adjustment operations should

be carried out on the half-bearings. Replace them

if scoring or signs of binding are noted.

22.The size of the main journal half-bearings is given.

Main journal half-bearings -

1.836 ~ 1.841

CategoryA (red) (mm)

Main journal half-bearings -

1.841 ~ 1.846

Category B (blue) (mm)

Main journal half-bearings -

1.846 ~ 1.851

Category C (yellow) (mm)

Main journal half-bearings

0.127

thickness oversize (mm)

Crankpin half-bearings -

1.546 ~ 1.552

CategoryA (red) (mm)

Crankpin half-bearings -

1.550 ~ 1.556

Category B (blue) (mm)

Connecting rod half-bearing

0.127

thickness oversize (mm)

23.The size of the connecting rod half-bearings is given.

24.Place the upper main bearing halves in their seats

taking great care over cleanliness.

NOTE :

Half-bearings of different categories may be fitted to

the same journal to reduce the clearance. In the above

case, observe the following installation requirements:

Fit the thickest half-bearing to the main bearing cap

and the thinnest to the crankcase.

If the crankshaft has been ground, fit new oversize

half-bearings to restore the initial tolerance conditions.

The thrust half-rings are built into the central main

bearing half.

25.The thrust half-ring thickness should be within the

specified limits of 2.310 mm ~ 2.360 mm.

NOTE :

The thrust half-washer undersize is 0.127 mm.

26 Fit the crankshaft into its seat on the upper

crankcase.