DRIVETRAIN-TA65 Star

63

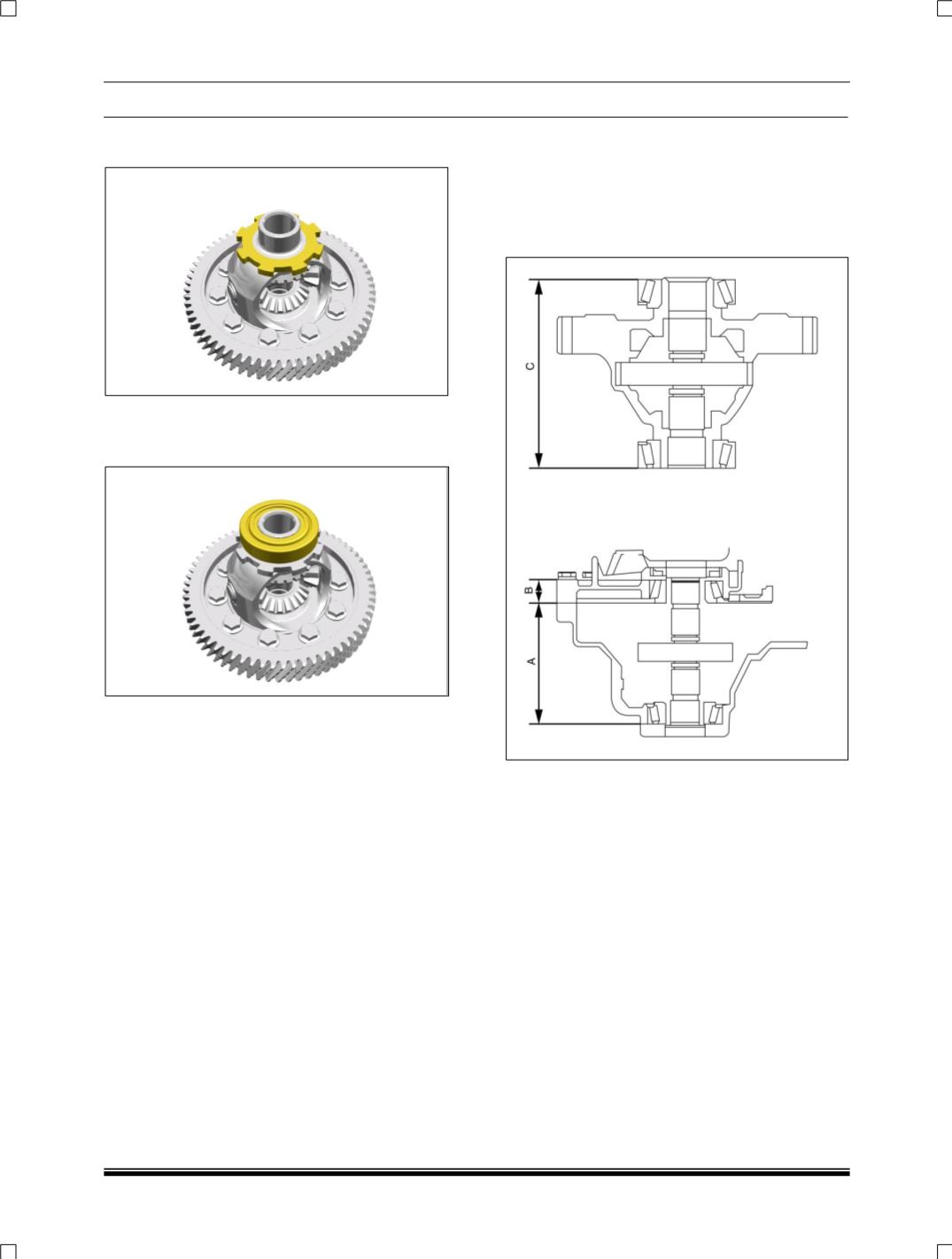

10. Fix sensing wheel with recess inside using

drift part No. 2654 5890 3507.

11. Press taper roller bearings using drift part

no. 2702 5890 2608 on either side of

differential housing.

4.7. R. ASSEMBLIES OF TRANSAXLE:

1. Fit clutch release fork shaft. Fit plastic

bushes. Fit lever on clutch release shaft and

lock it by grooved pin.

2. Differential bearing preload adjustment

procedure.

Measure dimension ‘A’ (Distance between top

mating surface of transaxle front half and the

outer differential bearing seat) say 103.7mm

in housing and dimension ‘B’ (Distance

between mating surface of transaxle rear half

and the inner differential bearing seat) say

19mm in housing for bore 65.088 mm dia.

Place outer races on both differential side

bearings and measure distance between

outer surfaces of these outer races

(dimension ‘C’).

Select shim thickness = (A+B) - C to (A+B) -

C+ 0.05 and install the shims against front

half taper roller bearing outer race.