1.05L REVOTORQ ENGINE

93

B. ENGINE INSTALLATION :

1. Engine installation is generally reverse of

removal. Make certain all hardware is

tightened to appropriate torque specification.

2. Prior to installing the engine, inspect the

condition of the rubber on the engine mounts.

Replace the engine mounts if the rubber is

damaged.

3. Install the starter motor, AC Compressor,

alternator along with its mounting brackets.

4. Mount the transaxle back onto the engine.

Tighten the bolts with specified torque.

5. With the vehicle raised on the vehicle lift

hoist, place the engine underneath the

vehicle,

aligned

with

the

engine

compartment.

CAUTION

Use care when lowering the vehicle body to

the engine and transaxle assembly. Verify

all the engine and other components will

not make direct contact or vehicle damage

will occur.

6. Slowly and carefully lower the vehicle body

over the engine.

7. Connect the lifting crane to the engine with a

chain / belt. Raise the hoist slightly to apply

lifting tension to the engine.

8. With the engine attached to the crane,

remove the support stand.

9. Secure the engine in the vehicle by attaching

the "C", "A" and "B" mounting brackets.

Tighten the mounting bracket hardware at

specified torque.

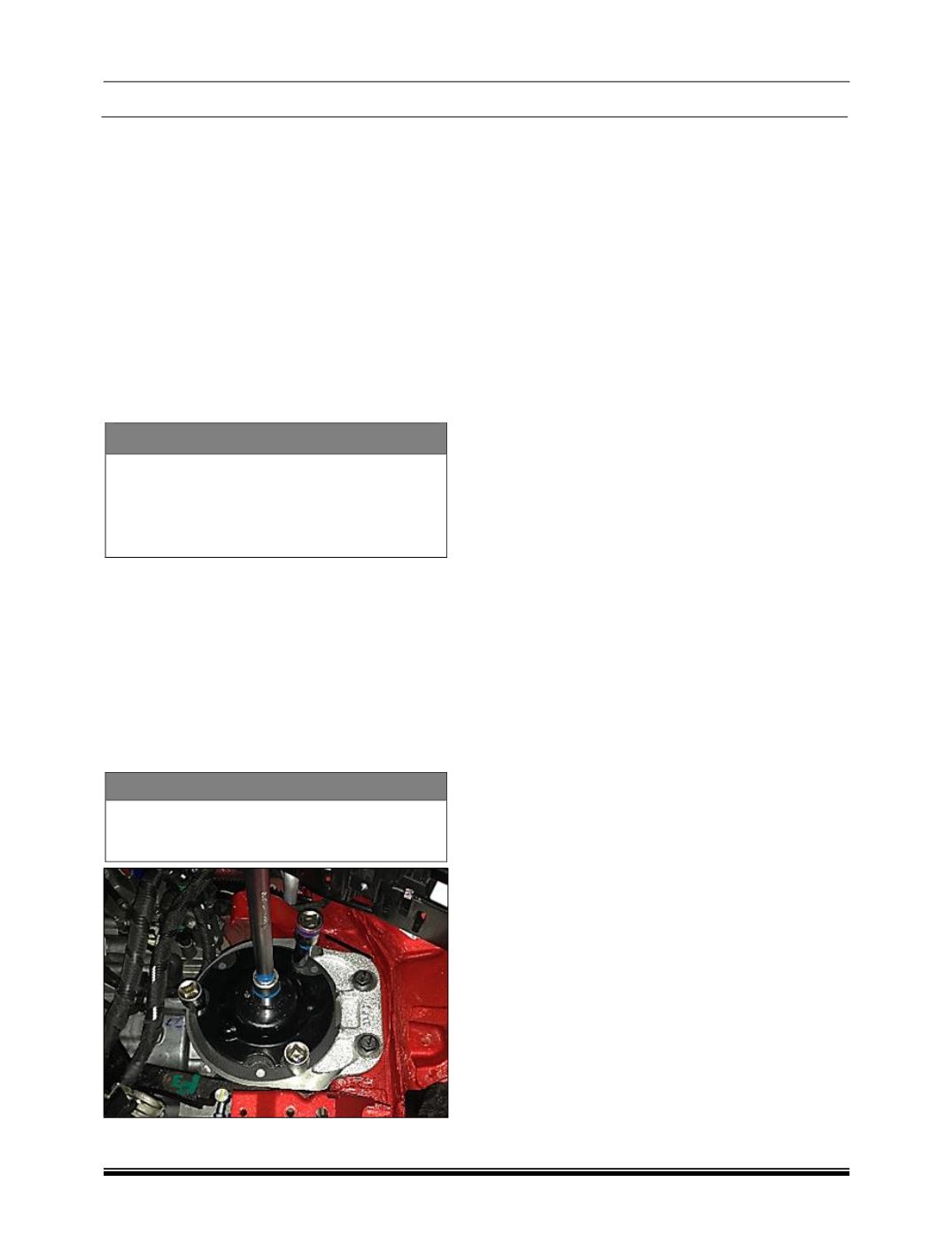

NOTE

While tightening of B mount, use 12 mm 3

no’s of sockets on consecutive 3 mounting

bolts as shown in fig.

10. Remove the chain / belt after engine mounts

are secure.

11. Install the left and right driveshaft assemblies.

12. Connect the gearshift linkage, clutch cable to

the engine and transaxle.

13. Connect the engine wiring harness.

14. Connect the cooling system reservoir hoses.

Verify the cooling system drain is closed on

the radiator. Install the cooling system hoses

to the engine, radiator and heater core.

15. To connect the exhaust front pipe tighten the

flange near Catcon and connect at rear end.

16. Install the air filter assembly and intake

system hoses to the engine.

17. Connect the vacuum hose connected

between brake booster to vacuum pump.

18. Connect all the hoses connected between

radiator and engine.

19. Connect the fuel lines to the engine.

20. Install the Battery Plate, Battery and ECU.

21. Connect the engine wiring harness

connection with ECU.

22. Add the appropriate quantity of Engine oil,

Transaxle oil and coolant with respective

systems.

23. Connect the battery positive cable and then

the battery negative cable.

24. Crank the engine several times without

allowing the vehicle to start. This allows the

oil and coolant to flow through engine.

25. Start the engine and verify the oil pressure

light on the instrument cluster goes out. Stop

the engine immediately if the light fails to

extinguish.

26. Allow the engine to run for several minutes,

checking for fluid levels and leakage.