3 CYL DIESEL ENGINE

57

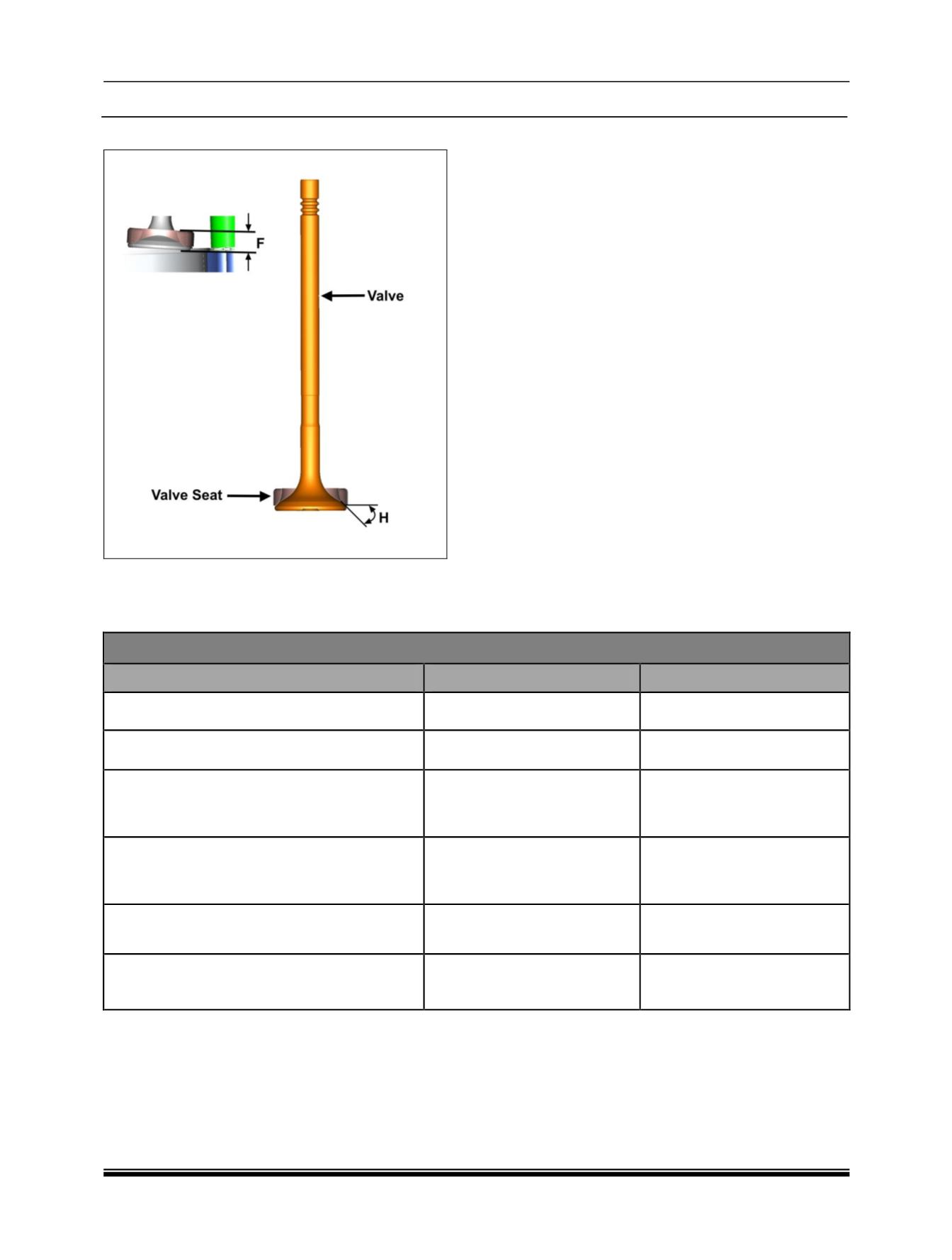

E. VALVE SEATS :

1.

Check valve seat height with respect to

cylinder head mating surface. Replace valve

seat inserts if they are worn out beyond

specified limit.

2.

Cut exhaust and inlet valve seats with a

general 45 deg. cutter.

NOTE

Valve seat must be absolutely faultless and

without any chatter marks

3.

If necessary lap the valve seats to a smooth

and even finish by using suitable hand pump

grinder or a lapping paste and valve itself.

4.

Smear valve seat with carbon blue. Install

valve in guide and turn it slowly under axial

pressure.

5.

Contact line on valve seat must be around

entire circumference at equal width.

6.

Distance between narrow diameters of valve

face to contact line should be minimum 0.5

mm.

7.

Check for leakages through valve seat by

pouring gasoline on valve head. Gasoline

must not seep past valve seat.

Valve seat Specifications

Dimensions

Intake Valve

Exhaust Valve

Valve Seat Angle 'H'

45°/5°

45°

Valve seat Diameter in Cylinder head

27.5

0.021/0.000

mm

23.4

0.021/0.000

mm

Distance ‘F’ between Cylinder head

mating Surface with crank Case to

Valve Seat in Cylinder head

7 ± 0.1 mm

7 ± 0.1 mm

Maximum run out of Valve Seat in

Cylinder Head with Respect to Valve

guide axis

0.035 mm

0.035 mm

Valve Seat Inner Bore Dia. in Cylinder

Head (mm)

Normal : 27.5

0.021/0.000

Normal : 23.4

0.021/0.000

Valve Seat Insert Outside Bore Dia. in

Cylinder Head (mm)

Normal : 27.6

+.0.000/-0.013

Normal 1 : 27.8

+.0.000/-0.013

Normal : 23.5

+.0.000/-0.013

Normal 1 : 23.7

+.0.000/-0.013