1.05L REVOTORQ ENGINE

56

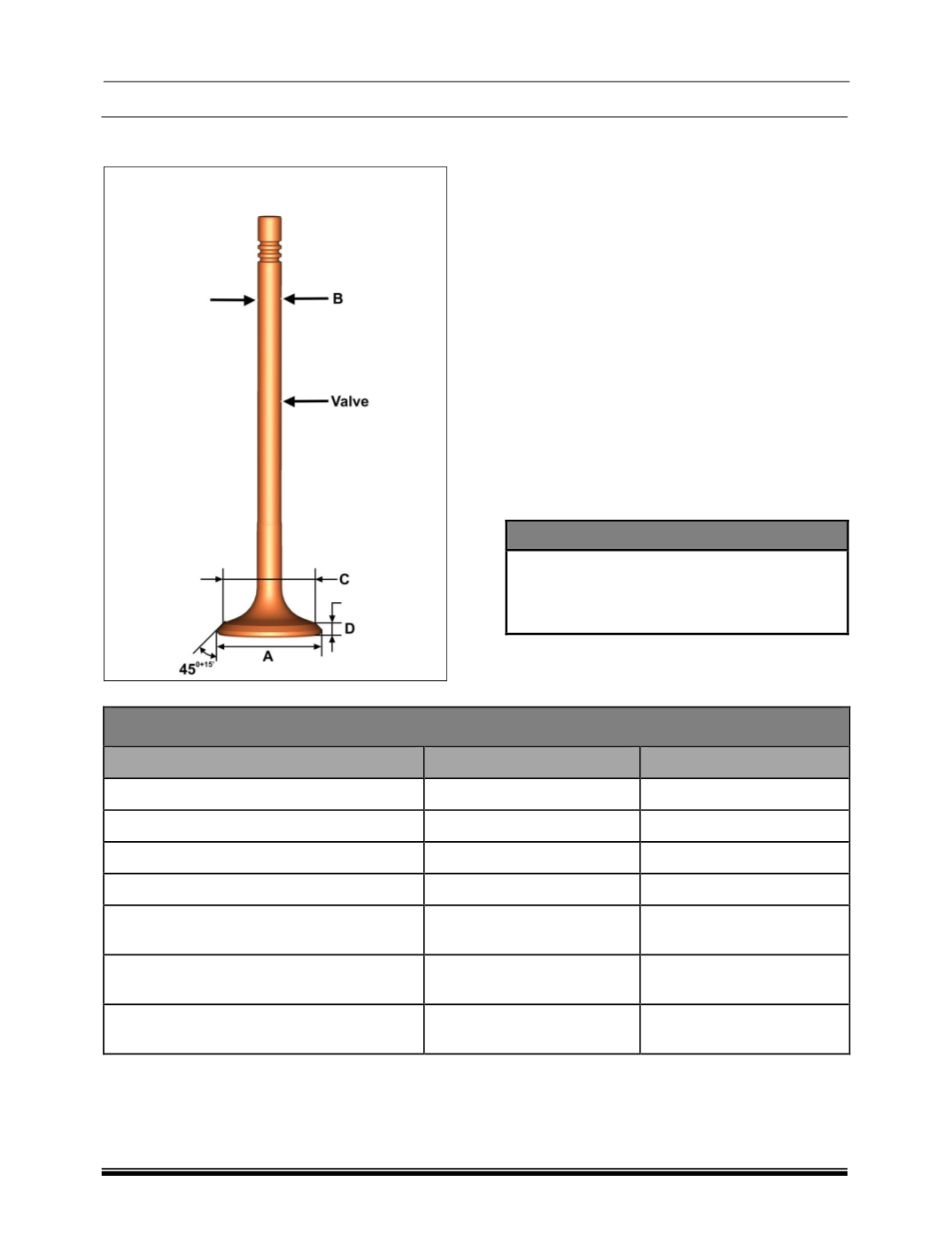

D. VALVES :

1. Check valve leakages by pouring gasoline on

valve head. Gasoline must not seep past valve

seat.

2. Valves with burnt heads, excessive scoring

and wear on stem should be replaced.

3. Check valve seat run out with respect to valve

stem. If it exceeds specified limit replace valve.

No attempt should be made to straighten bent

valves.

4. If valve is free from any other defects except

worn out seat, then only it can be rematched

on valve grinding machine as follows:

Clamp valve on grinding machine jaws as

close as possible to valve head.

Adjust grinding angle on graduated scale to

achieve correct valve seat angle.

Feed valve slowly towards grinding wheel

until wheel just touches valve head.

Grind at low feed until valve seat is just

clean all around.

NOTE

After machining the valve seat, remove the

valve from the grinding machine and check

valve head thickness. The minimum valve

head thickness of the valve is 0.85 mm.

Valve Dimensions

Dimensions (Callout)

Intake Valve

Exhaust Valve

Valve Head Diameter (A)

Ø25.8 ± 0.1 mm

Ø22.6 ± 0.1 mm

Valve Seat Angle

45° + 15’

45° + 15’

Valve Stem Diameter (B)

Ø5.973 ± 0.007 mm

Ø5.953 ± 0.007 mm

Valve Seat Diameter (C)

24.5 mm

20.7 mm

Valve Seat End Distance From Valve

Face (D)

2.00 ± 0.08 mm

2.25 ± 0.08 mm

Maximum Run out of Valve Face with

Respect to Valve Stem

0.1 mm

0.1mm

Maximum Run out of Valve Face with

Respect to Valve Stem (C-B)

0.003 mm

0.003 mm