1.05L REVOTORQ ENGINE

59

G. VALVE SEAT INSERT :

1. For removing valve seat inserts from cylinder

head use suitable boring machine. Bore old

insert thin (About 0.5 mm thickness) and then

pry it out.

2. Alternatively use a suitable turning tool to cut

an annular groove into valve seat insert and

then pull it out with a suitable puller. In order

to avoid damaging machined cylinder head

mating surface with crank case, place any soft

protective sheet metal under supports of

puller.

3. Measure valve seat insert bore diameter in

cylinder head.

4. If boring and prying is done carefully without

damaging valve seat insert bore in cylinder

head, fitment of an over size valve seat insert

will not be necessary.

5. Re-machined valve seat insert bore in

cylinder head must be exactly at right angle to

cylinder head mating surface with crank case.

6. All specified dimensions should be strictly

maintained to ensure proper interference of

valve seat insert in its bore.

7. Clean valve seat insert and its bore in cylinder

head thoroughly.

JUST BEFORE INSTALLATION

1. Place valve seat insert in mixture of Methanol

and dry ice for about 20-30 minutes to bring

temperature down to -150ºC.

2. Heat cylinder head to approximately 80ºC in

hot water bath.

3. Install valve seat insert in cylinder head bore

quickly by light hammering.

4. Machine valve seat in cylinder head.

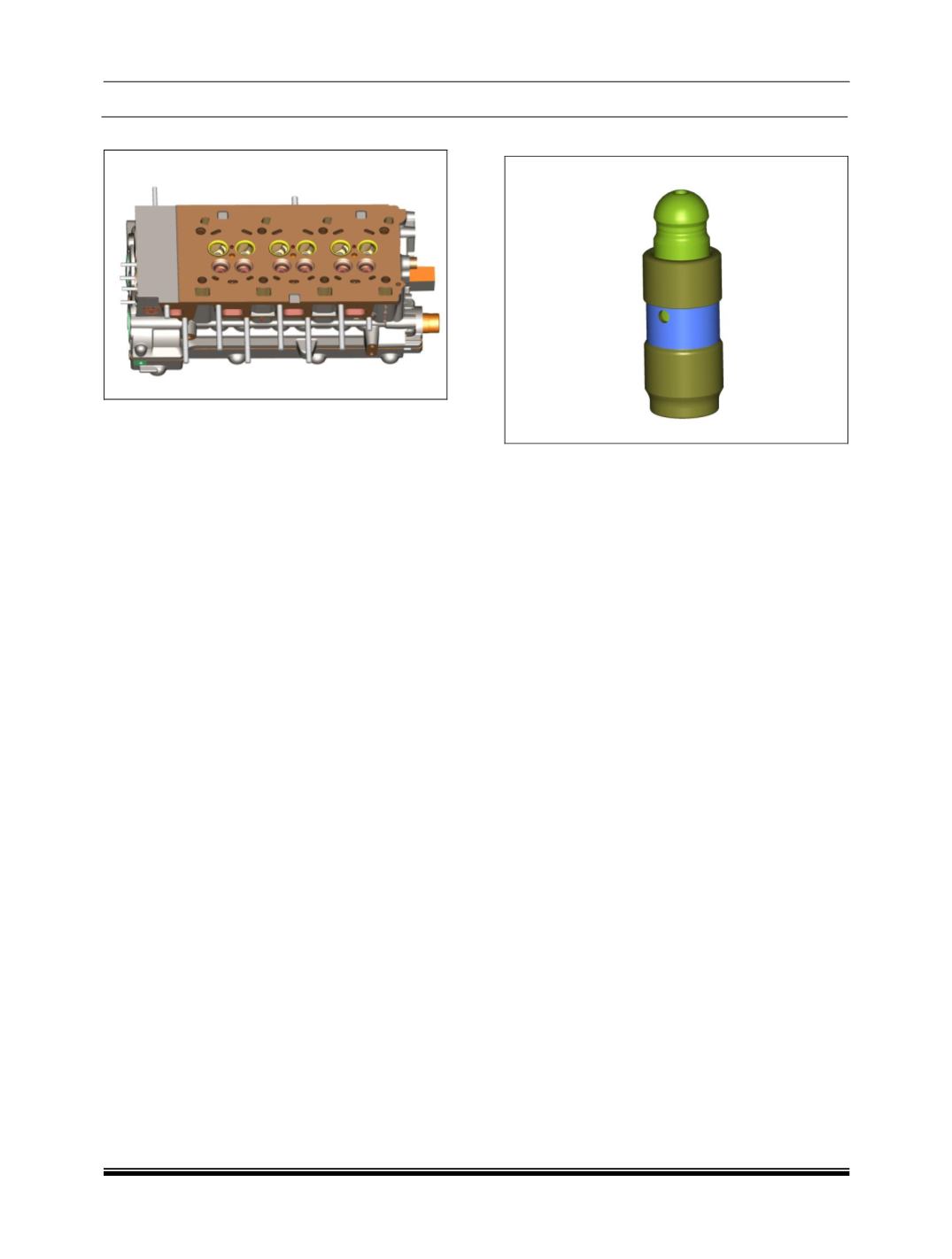

H. HYDRAULIC LASH ADJUSTER :

1. Hydraulic Lash Adjuster supports the pivot

end of the rocker arm while automatically

controlling the rocker arm position to keep it in

contact with the camshafts and valve.

2. The range of the hydraulic lash adjuster

accommodates engine build tolerances;

hence no adjustment is required during

engine assembly. It also compensates for

variation that occurs during the life of the

engine.

For information on HLA and inspection refer

Lubrication section.