1.05L REVOTORQ ENGINE

62

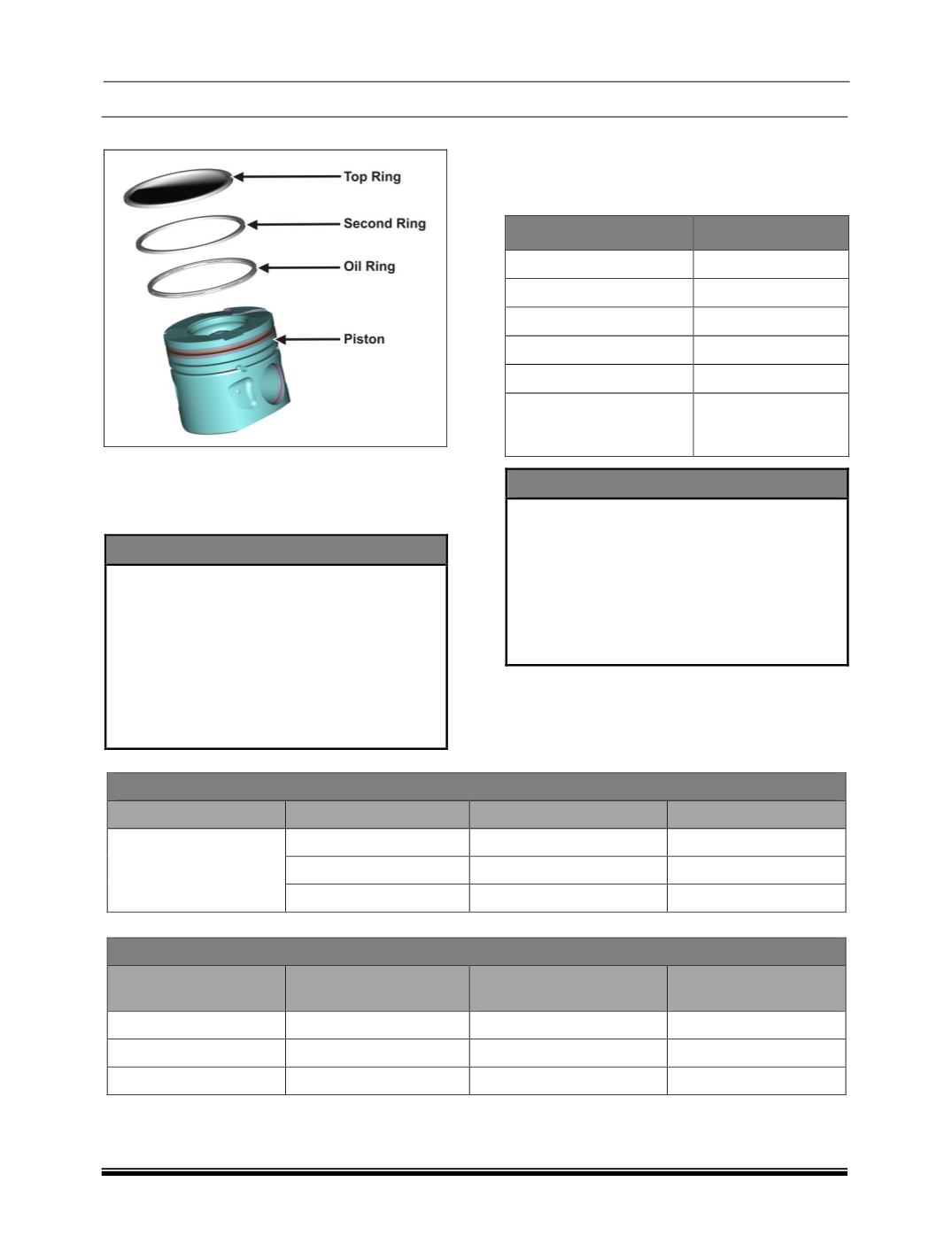

K. PISTON AND PISTON RINGS :

1. Remove carbon deposits, if any, from the

piston.

2. Clean piston and piston rings using

appropriate cleansing agent.

NOTE

The piston and piston rings can be reused

if the bore taper and sphericity is within the

specified limits.

Carefully examine the piston rings for

cracks, scoring, ring groove/ clip groove

wear, piston pin bore wear.

In case anyone piston is found to have any

one of the above defects, replace the

complete piston set.

3. Check for lateral clearance in piston ring

groove.

4. Check for butt clearance in cylinder bore.

5. Check for piston pin dimensions.

Details

Specification (mm)

Piston pin diameter

27

-0.005

Piston pin length

62

-0.3

Piston pin bore in piston

27

-0.013/-0.007

Height of piston

67

Piston to bore clearance

0.06 - 0.08

Maximum permissible

difference in weights of

piston with pin and rings

1.5 gms

NOTE

Butt clearance of piston ring is measured in

unworn portion of the cylinder bore.

Piston and piston rings of appropriate size

should be used, if cylinder bores are re-

bored.

If piston ring is found to be defective as

started above, then complete ring set

should be replaced.

Piston and Cylinder Bore Sizes

Type

Grade

Cylinder Bore Dia. (mm)

Piston Dia. (mm)

Standard

A

75.00 / 75.009

74.93 / 74.939

B

75.01 / 75.019

74.94 / 74.949

C

75.02 / 75.03

74.95 / 74.96

Piston Rings

Type of ring

Ring Thickness (mm)

Axial Clearance in

Piston Groove (mm)

Butt Clearance in

Cylinder Bore (mm)

1

st

Compression Ring

2.5 (Nominal)

----------

0.25 / 0.45

2

nd

Compression Ring

1.99 / 1.97

0.08 / 0.04

0.4 / 0.6

3

rd

Oil Control Ring

2.99 / 2.97

0.03 / 0.07

0.25 / 0.45