1.05L REVOTORQ ENGINE

63

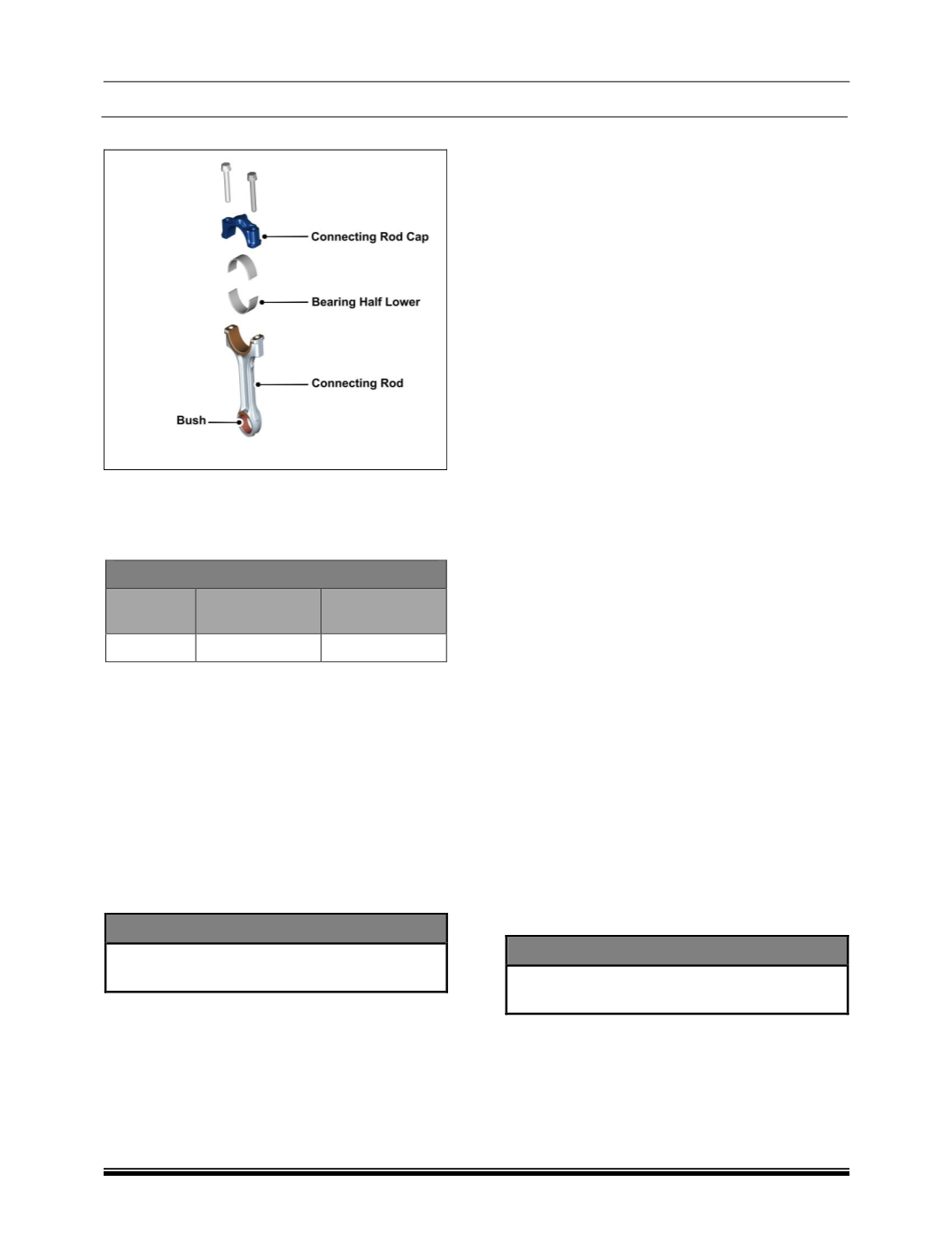

L. CONNECTING ROD :

1. Inspect connecting rod small end bush and if

necessary, replace it.

2. Check connecting rod small end parent bore

dimension.

Connecting Rod – Small end Dimensions

Stage

Parent Bore

Diameter (mm)

Bush – outer

Diameter (mm)

Standard 30±0.025/0.000

30.112

3. If necessary machine connecting rod small

end parent bore to next over size.

4. Ensure that connecting rod big end and small

end axis are parallel to each other and are

within specified limits.

5. Ensure that the centre distance between

small end to big end is maintained within

specified limit.

6. Smear oil on parent bore of connecting rod.

7. Install new bush in such a way that slits are

symmetrically positioned approximately in the

vertical axis.

NOTE

If required Machine the side faces of bush

to match the taper faces of connecting rod.

8. Finish connecting rod small end bush bore on

a connecting rod boring machine.

9. Alternately connecting rod small end bush

may be reamed. The end edges to be

chamfered / deburred manually.

10. Install connecting rod bearing caps without

bearing shells on connecting rod.

11. Tighten connecting rod bearing cap mounting

nuts to specified torque.

12. Ensure that identification numbers for

connecting rod and connecting rod bearing

cap are matched and notches for bearing

shells are on the same side.

13. Check twist and bend of connecting rod by

using new piston pin in connecting rod small

end bush.

14. Measure twist and bend of connecting rod

with feeler gauge with respect to vertical face

of the connecting rod alignment gauge in

vertical and horizontal plane at a distance of

50 mm from line joining centers of connecting

rod small end and big end bosses.

15. Check connecting rod big end parent bore

dimension.

16. If connecting rod big end parent bore is

slightly more than maximum permissible

limits, it is possible to reclaim the connecting

rod provided the wear is confined only to

connecting rod bearing cap. In such cases the

connecting rod bearing cap mating surface

can be slightly faced. The parent bore should

then be finished on a connecting rod boring

machine.

17. Ensure that the connecting rod big end and

small end axis are parallel to each other

within the specified limits. Centre to centre

distance between connecting rod small end

and big end is maintained within specified

limits.

18. If one or more connecting rods are to be

replaced, ensure that difference in weight of

connecting rod in one engine is within

permissible limits.

19. Install new pair of connecting rod bearing

shell according to size of crank pin journal

diameter, making sure that securing lugs of

bearing shells are properly seated in grooves

of connecting rod and its bearing cap.

NOTE

Lower and Upper bearings are not

interchangeable.

20. Install connecting rod bearing cap with

bearing shell on connecting rod. Tighten

connecting rod bearing cap mtg. nuts to

specified torque.

21. Measure connecting rod bearing bore. Record

the readings in the format given in this

manual.