1.2L REVOTRON ENGINE

123

2.8 ENGINE OVERHAULING:

(ON OVERHAUL STAND)

A. Engine Assembly :

I. Assembly of Cylinder Block Sub-

Assemblies

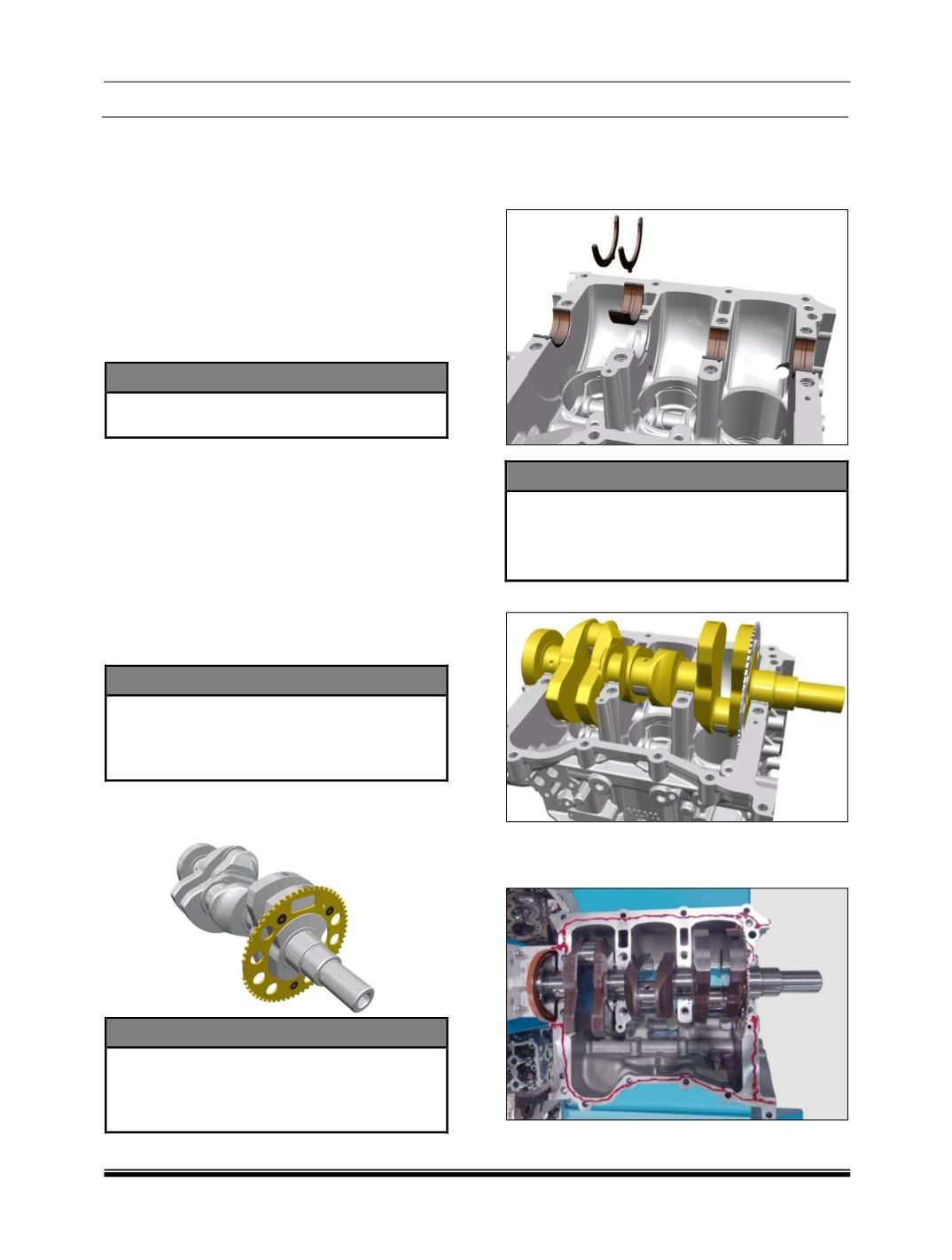

1. Check cylinder block for cracks by pressure

testing method. Clean cylinder bores, bearing

surfaces, oil passages in crank case

thoroughly. Check water jackets for leakages

by blowing air at a pressure of 5 bar & then

dipping the cylinder block in the hot water.

(Temp of water 70

0

to 80

0

C)

NOTE

The block with any leakages / cracks

should be discarded.

2. Check crankcase mating surfaces with

cylinder head for unevenness with the help of

straight edge and feeler gauge. If necessary

grind this surfaces just to clear unevenness.

Measure across the length and breadth to

specific mention value in table.

3. Ensure main bearing parent bore dimensions

are within specified limits. (For specified limit

and procedure refer cylinder block inspection

chapter.)

4. Ensure that the minimum height of crank case

is not less than the specified minimum height.

NOTE

Apply light coat of grease to the fourth

main bearing cap.

Ensure the slot on thrust washers are

facing on outer side.

5. Tighten the hex socket counter sunk screw to

join the crank sensor target wheel to

crankshaft.

NOTE

Ensure the dowel pin.

While replacing target wheel or ECU we

have to do flywheel learning (for procedure

refer page no 147 of petrol Engine.)

6. Match the lug of thrust washer with block.

7. Insert the thrust washers from 3

rd

bearing

from cylinder block and place the upper

bearing shell. (Apply the coat of engine oil.)

NOTE

Apply light coat of engine oil to all main

bearing shells and crankshaft journals.

Ensure crankshaft holes are properly

cleaned and free from any blockages.

8. Place the crankshaft.

9. Spread the liquid red sealant on crankcase

without spilling the sealant in oil paths / inside

the block.