1.2L REVOTRON ENGINE

63

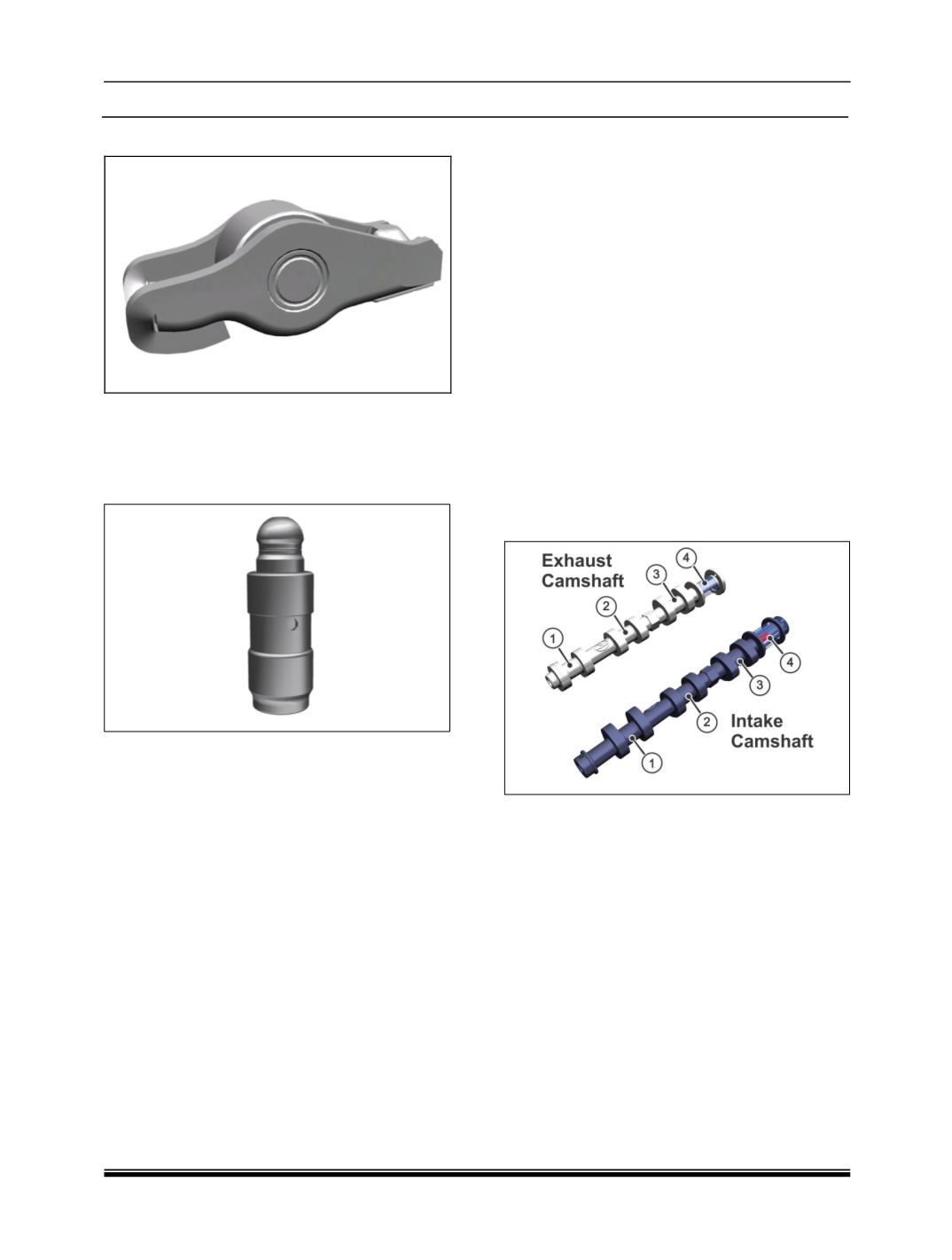

F. Roller Finger Follower :

1. Measure the diameter along several points of

both rocker arm roller. The rocker arm roller

diameter should be Ø17.0 -0.016/-0.027 mm.

Replace the rocker arm if deformed.

G. Hydraulic Lash Adjuster (HLA)

Hydraulic lash adjuster uses Engine oil pressure

for its operation. In case of a freshly assembled

Engine, do not run for a long time; there are

chances of valve train noise / tappet noise

appearing when the engine is started.

HLA noise can be heard as repeated tappet like

noise when engine is running at low idle speed.

Following procedure is recommended to eliminate

the noise.

Raise the Engine speed to 500rpm without

load

(Vehicle stationary)

to bleed the

hydraulic chamber of HLA. The noise should

disappear in15-30seconds.

If the noise still persists, run the engine

further under same condition (no load at 500

RPM) for several minutes. The noise should

disappear in 3 to 30 mins, in few cases.

In a very rare case if the noise is still heard,

the HLA is stuck in compressed position and

has to be replaced

Oil pressure in HLA gallery to be 0.7 bar for

normal functioning.

H. Camshafts (Intake & Exhuast) :

1. Visually inspect the camshaft journals for

signs of overheating and score marks.

2. Visually inspect the camshaft lobes for signs

of excessive wear or score marks.

3. Place camshaft journal 1 and 4 in 'vee blocks'

and check camshaft journal runout on

journals 2, and 3 using a dial indicator. The

maximum journal runout is 0.020 mm

4. Measure the diameter of each of the camshaft

journals. Refer the table for acceptable

journals diameters.

5. Use a bore gauge to measure each of the I.D.

of camshaft bearings. Refer the table for

acceptable bearing diameters.

6. Use a magnetic crack detector to check the

camshaft for cracks.

7. Check the camshaft lobes for proper

hardness. The Rockwell Hardness should be

a minimum of 40 HRC at 3mm (chill) on the

'C' scale.