1.2L REVOTRON ENGINE

66

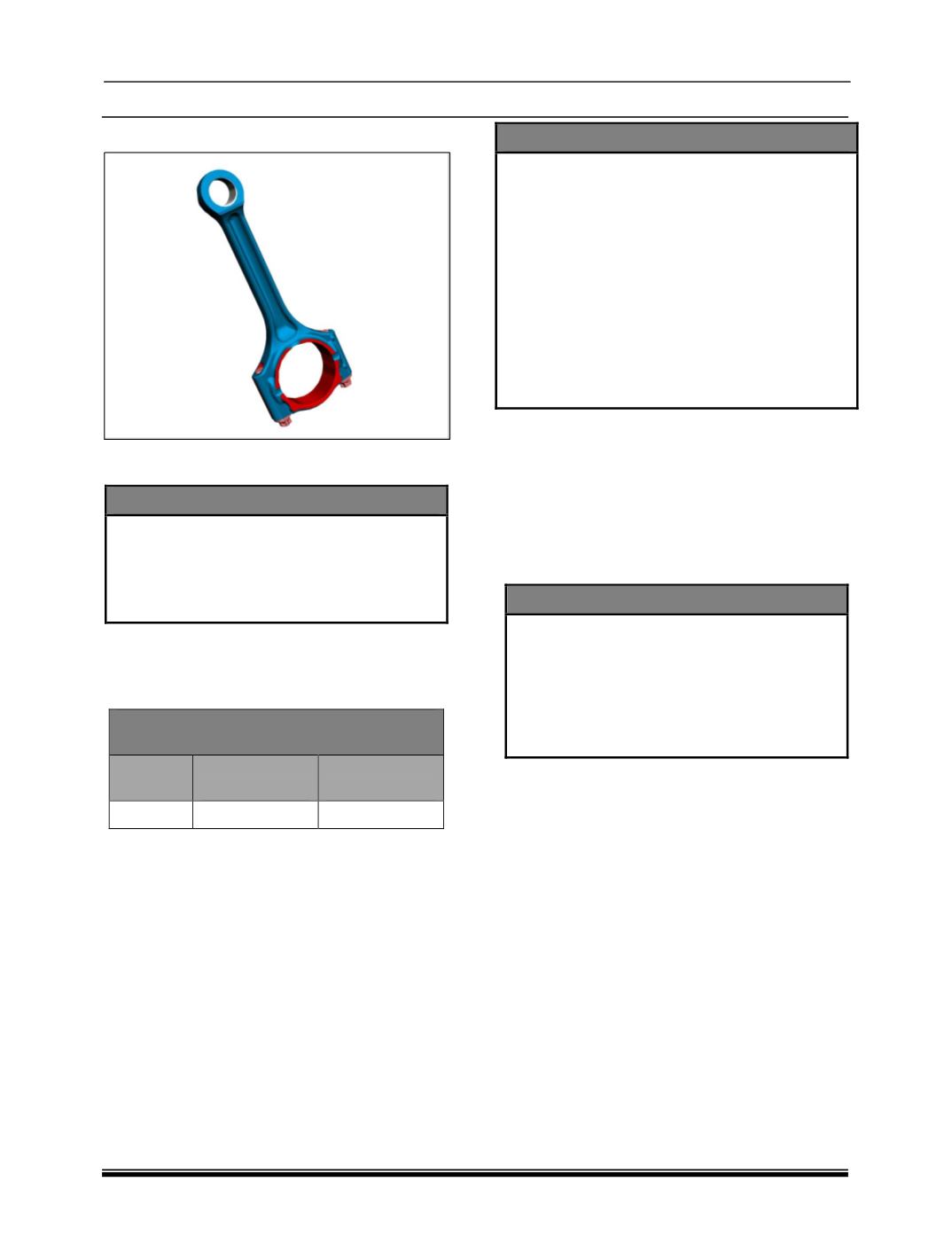

J. Connecting Rods :

1. Inspect the small end bush of connecting rod,

and measure piston-pin bore.

NOTE

Ensure that the connecting rod big end and

small end axes are parallel to each other.

Ensure that the Centre distance between

big end and small end is maintained within

the specified limits.

2. Install connecting rod bearing caps without

bearing shells.

3. Tighten connecting rod bearing caps

mounting bolts to the specified torque.

Connecting Rod – Small end Dimensions

(Revotron 1.2T)

Stage

Parent Bore

Diameter (mm)

Bush – outer

Diameter (mm)

Normal 21.000 - 21.021 21.055 – 21.095

4. Check for twist and bend of connecting rod by

using new piston pin at connecting rod small

end.

5. Using feeler gauge, measure twist and bend

of connecting rod with respect to vertical face

of connecting rod alignment gauge in both

vertical and horizontal plane at distance of

50mm, from the line joining centers of

connecting rod big and small end bushes.

6. Install new pair of connecting rod bearing

shell, depending on the size of crank pin

journal diameter. Make sure the securing lugs

are in the grooves of connecting rod and its

bearing cap.

7. Install connecting rod bearing cap with

bearing shell on connecting rod. Tighten

connecting rod bearing cap mounting nuts to

specified torque.

NOTE

Correct bearing bore dimensions can be

achieved if connecting rod big end parent

bore dimension is maintained.

Measure pre-tension of connecting rod

bearing shell with a feeler gauge after

loosening connecting rod bearing cap

mounting nuts.

8. Measure connecting rod big end parent bore

dimension. If connecting rod big end parent

bore is slightly more than maximum

permissible limits, then the connecting rod

can be reclaimed provided the wear is

confined to connecting rod bearing cap. If the

mating surface of the connecting rod bearing

cap is slightly faced, then the parent bore

should be given a finishing on a connecting

rod boring machine.

9. If one or more connecting rods are to be

replaced, the difference in weight of

connecting rod should be within the

permissible limit.

NOTE

Straighten the connecting rod in cold

condition, if necessary.

As there is a slight clearance between

connecting rod bolts and corresponding

connecting rod bearing cap holes, it is

possible while installing the connecting rod

bearing cap will be off center, by which

dimension of connecting rod big end parent

bore will be different in different conditions.

If difference exists, connecting rod bearing

cap can be centralized by lightly tapping with

mallet, in the required direction after loosening

connecting rod bearing cap mounting nuts.