1.2L REVOTRON ENGINE

60

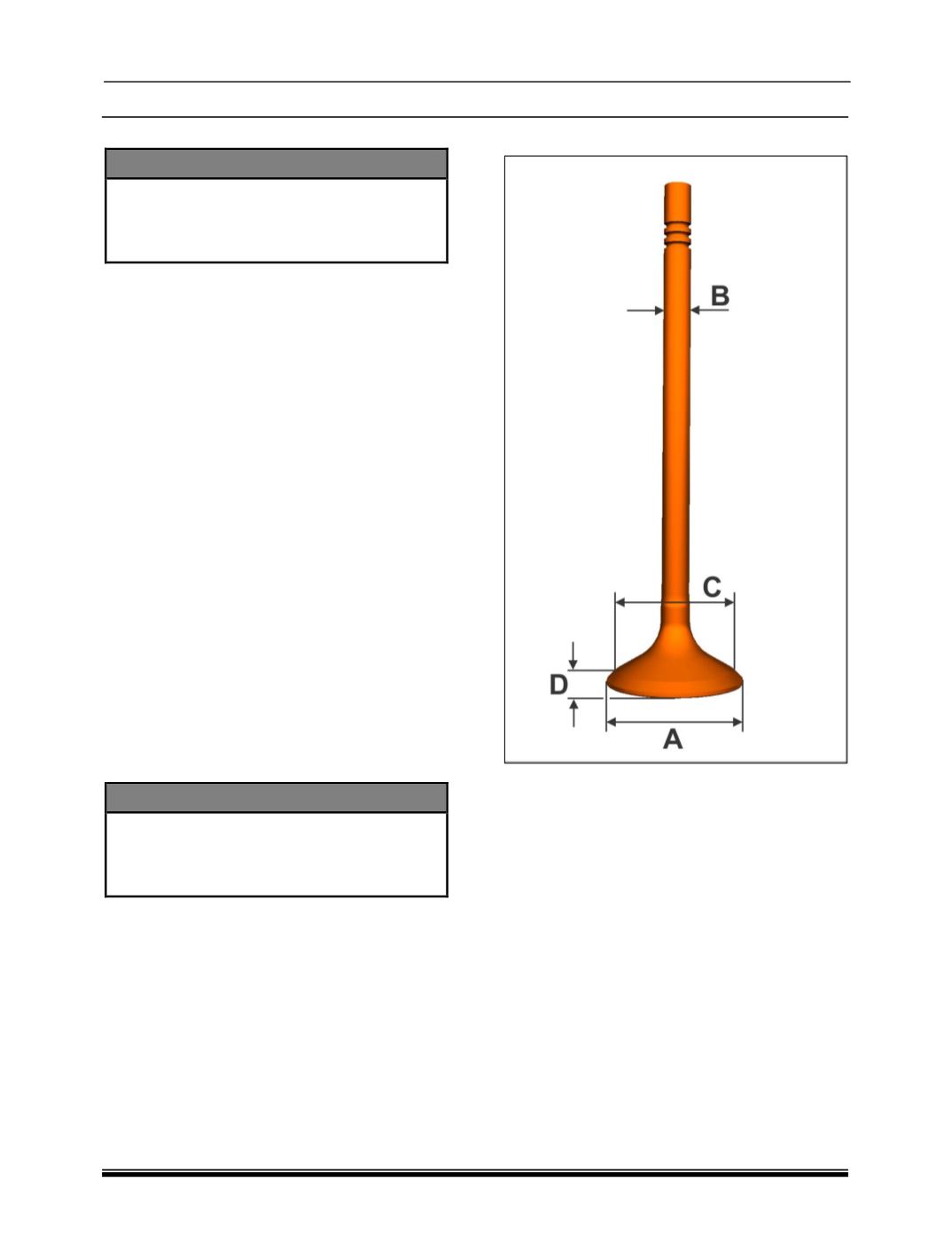

D. Valves :

DANGER

Petrol and Petrol fumes are extremely

explosive!! Use caution when working with

gasoline, otherwise explosion or fire may

occur, causing severe burns or death.

1. Check for leakage past the valves and valve

seats by placing the intake and exhaust

valves in the cylinder head and pouring

gasoline or isopropyl alcohol in the valve

chamber. Leakage indicates damaged valve

seats and/or valves. Note the location of each

valve so the valve can be matched to the

same location during reassembly.

2. Inspect each valve for damage. Do not

attempt to repair damaged valves. Replace

valves exhibiting the conditions in the

following list.

Burnt head or excessive carbon deposits.

Scoring or scratches on the valve surface

Excessive wear

Bend

3. Check for bent valves and excessive runout

between valve seat and stem by placing the

valve in a measuring fixture.

4. Place a dial indicator on the valve head and

valve stem and rotate the valve, observing

movement on both dial indicators.

5. The maximum permissible runout for both

exhaust and intake valve is 0.030 mm.

6. Measure the other valve dimensions listed in

table.

NOTE

Remove the valve from the grinding

machine and check valve head thickness.

The minimum valve head thickness of the

valve is 0.85 mm.

7. Rotate the valve under axial pressure several

times and remove from the cylinder head.

8. Inspect the area of contact created by the

axial rotation of the valve.

The contact pattern should be equal and

unbroken around the circumference of the

seat.

The distance from the narrow diameter of

the valve seat face to the contact line

should be 0.5 mm.