ENGINE 1.3L QUADRAJET (90PS)

61

32.After checking all the main journals, apply a strip

of specified silicon sealant to the contact surfaces

between the lower crankcase and the upper

crankcase as shown in the figure above.

NOTE :

The sealant strip must be unbroken. The sealant strip

diameter must be 2.5 - 3.5 mm.

33.After applying the sealant clean the crankshaft

lower oil seal seat.

34.Fit the lower crankcase to the upper crankcase

permanently by tightening the bolts as shown

previously.

35.Check that the small end bush bore (inner

diameter) diameter is within the recommended

limits of 23.006 mm ~ 23.012 mm; if not, replace

the connecting rod assemblies.

36.Check that the diameter of the gudgeon pin

housing in the piston is within the recommended

values of 22.990 mm ~ 22.996 mm.

37.If the piston pin bore diameter is not within

specified values, replace the piston complete with

its piston pin and rings.

38.Check that the outer diameter of the piston pins is

within the recommended limits of 22.982 mm ~

22.987 mm; if not, replace the worn piston pins.

39.Fit the piston rings in the cylinder bore and check

that the opening between the ends is within the

recommended values; if this is not the case,

replace the retaining rings.

40.Check that the thickness of the piston rings is

within the recommended limits.

41.Check that the piston ring seats are within the

following recommended values.

Sealing ring seat in piston - 1st groove (mm) 2.08 ~ 2.10

Sealing ring seat in piston - 2nd groove (mm) 1.54 ~ 1.56

Sealing ring seat in piston - 3rd groove (mm) 2.02 ~ 2.04

42 Check that the outer diameter of the pistons

corresponds to the recommended figures; if not,

replace the piston complete with piston rings and

gudgeon pin.

Piston outer diameter - Grade A (mm)

69.520 ~ 69.530

Piston outer diameter - Grade B (mm)

69.530 ~ 69.540

Piston outer diameter - Grade C (mm)

69.540 ~ 69.550

NOTE :

Measure perpendicular to the gudgeon pin axis, 12

mm from the lower edge of the skirt.

43.Check that the axial clearance between the first

ring and the housing in the piston corresponds to

the recommended figures of 0.09 mm ~ 0.13mm.

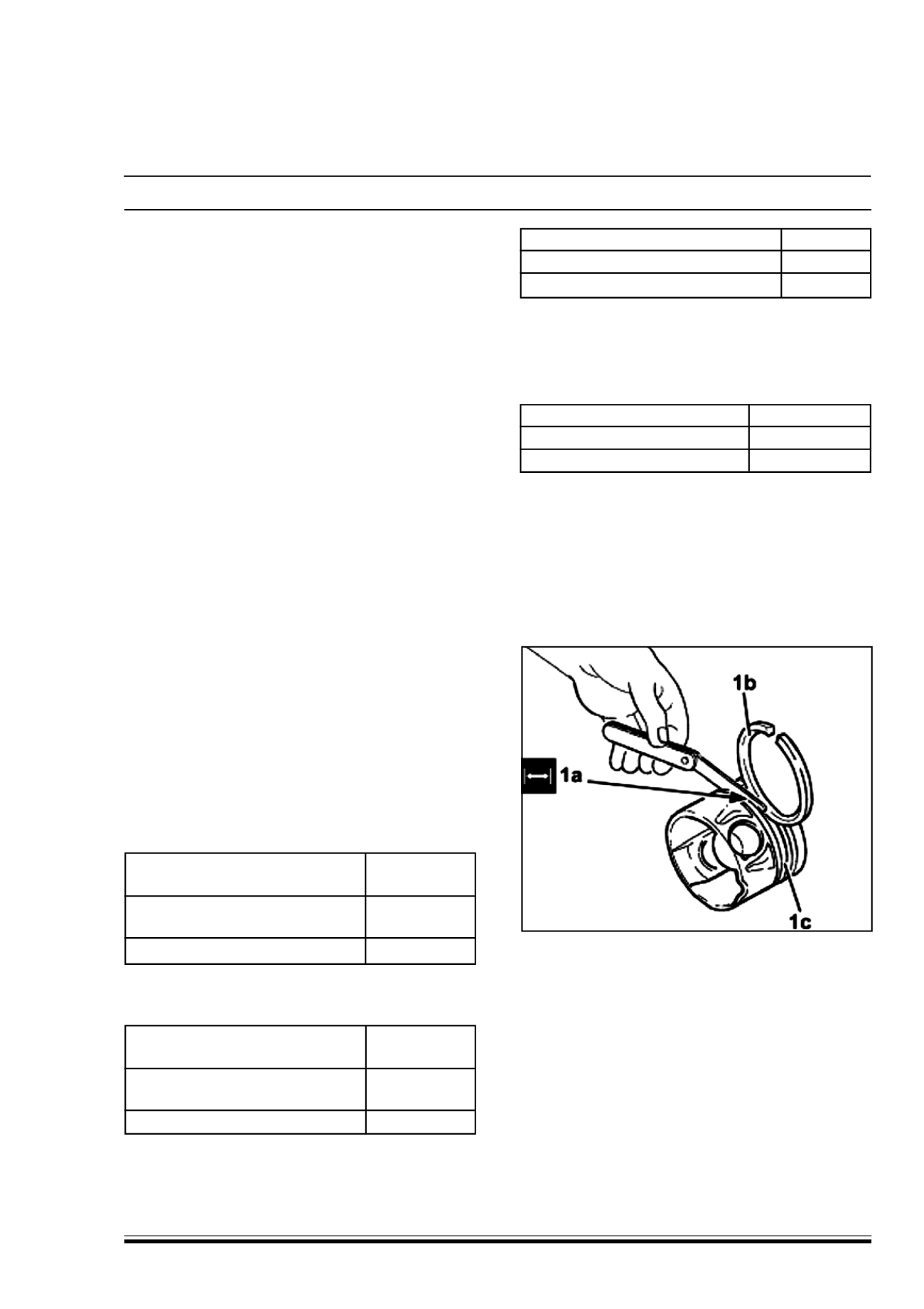

44.Check that the backlash (1a) between the second

ring (1b) and the housing in the piston (1c)

corresponds to the recommended figure of 0.04

mm ~ 0.08 mm.

45 Check that the backlash between the oil scraper

ring and the housing in the piston corresponds to

the recommended figures of 0.030mm ~

0.070mm.

Cylinder compression 1st sealing 1.970 ~ 1.995

ring thickness (mm)

Cylinder compression 2nd sealing 1.470 ~ 1.490

ring thickness (mm)

Piston oil scraper ring size (mm) 1.970 ~ 1.990

Cylinder compression 1st sealing 0.20 ~ 0.30

ring gap (mm)

Cylinder compression 2nd sealing 1.0 ~ 1.5

ring gap (mm)

Piston oil scraper ring gap (mm) 0.25 ~ 0.50