ENGINE 1.3L QUADRAJET (90PS)

65

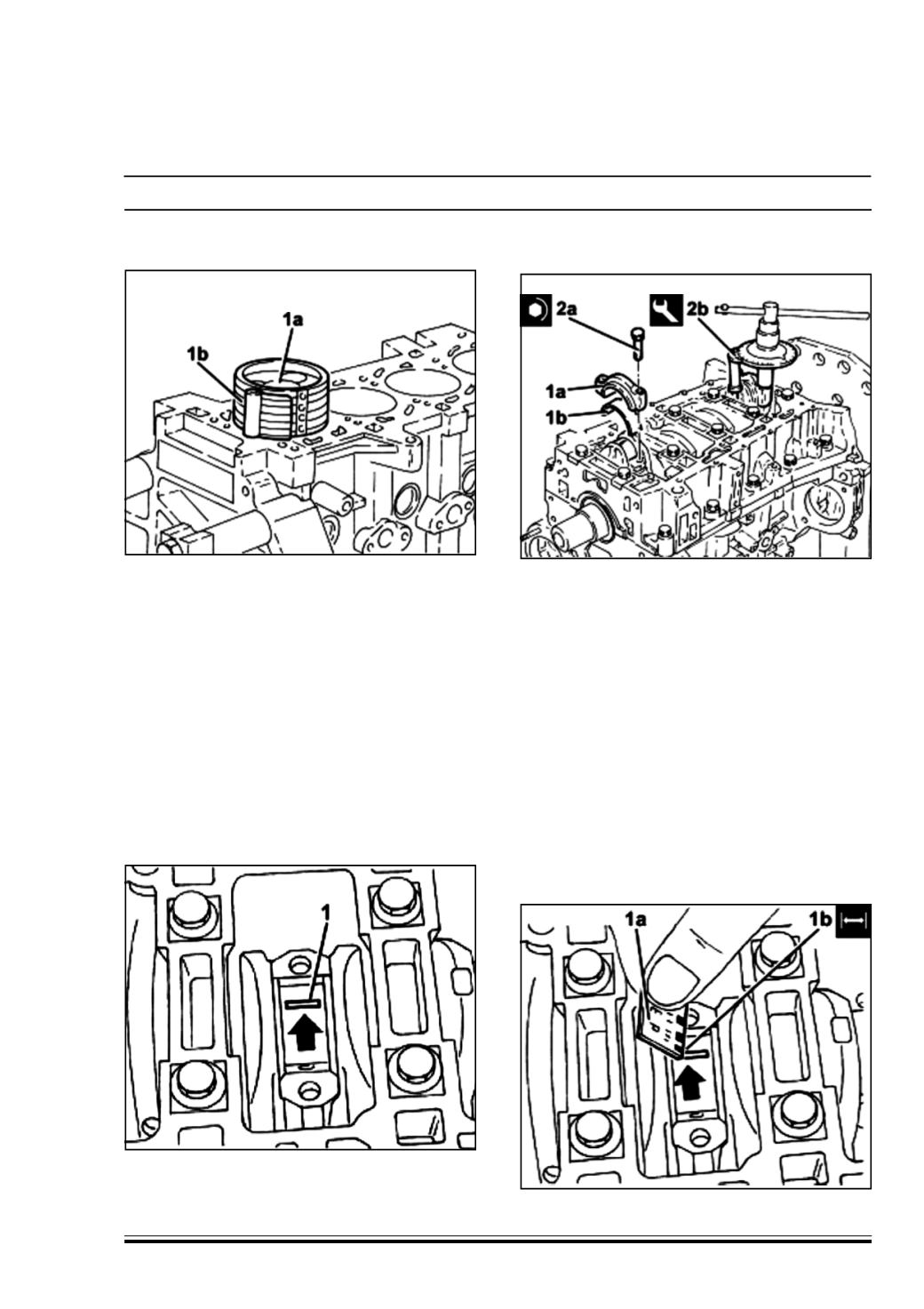

Exhaust (4a) on the piston skirt which should be

aligned with the oil jet (4b).

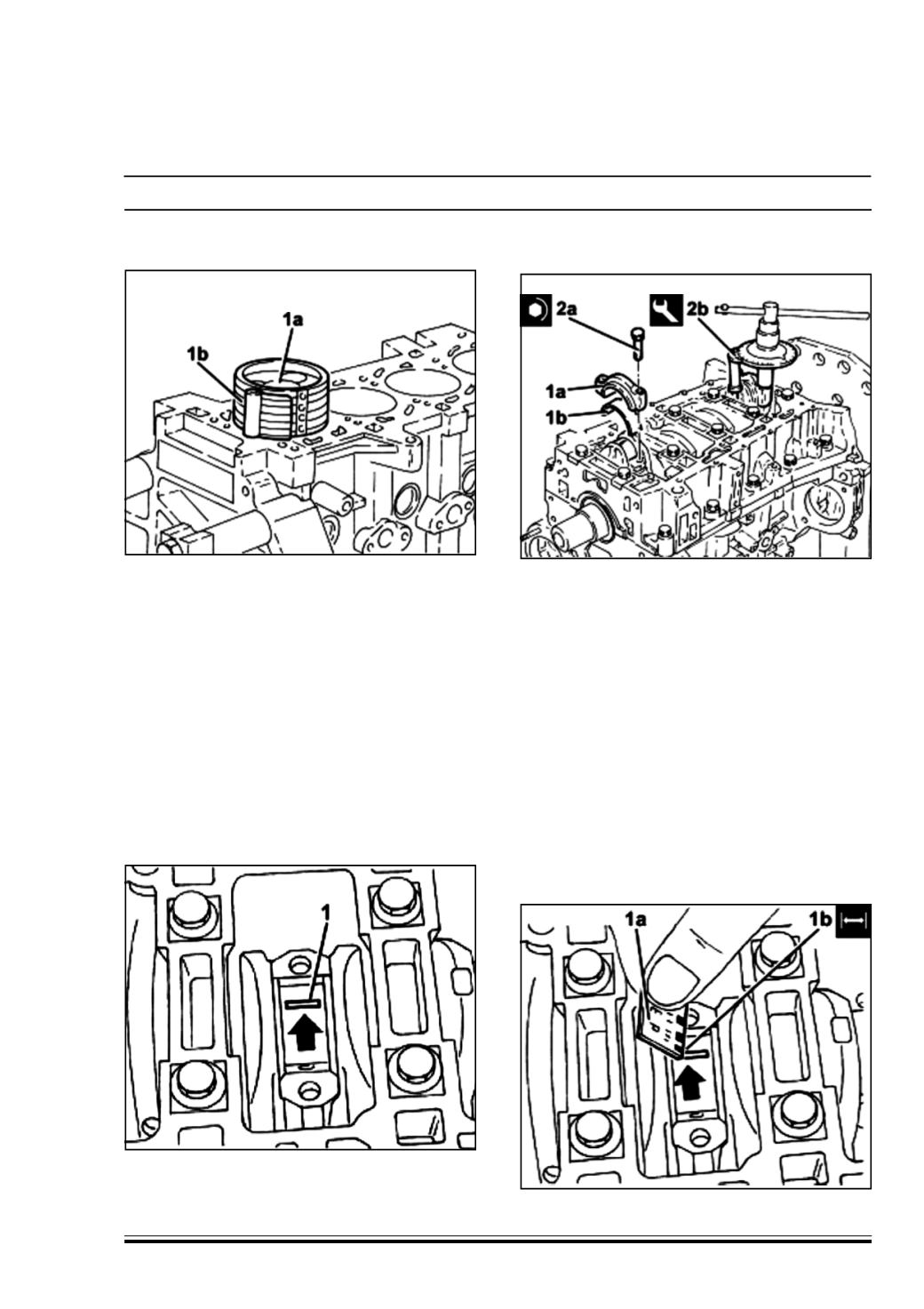

6. Fit the calibrated wire (plastic gage) (1) for

measuring the bearing clearance.

7. Refit the connecting rod cap assemblies (1a) in

their seats with upper connecting rod bearing halves

using tool (1b).

Check one journal at a time, without rotating the

crankshaft. upper connecting rod bearing half,

connecting rod side trimetallic and dark in colour- lower

connecting rod bearing half, cap side bimetallic, light

coloured with a hole Never reverse the positioning of

the connecting rod bearing halves under any

circumstances.

8. Tighten the connecting rod cap M8 bolts (2a) to

the recommended torque of 1.9 ~ 2.1 kg-m and a

tighten using the angular tightening tool (2b) to 40°

+/- 2°.

9. Remove the bolts and remove the connecting rod

caps with the half-bearings fitted previously.

4. Refit the piston-connecting rod assemblies (1a) in

their seats with upper connecting rod bearing halves

using tool (1b).

NOTE :

Q

The connecting rod bearing halvesmay be identified

as follows:

Q

upper connecting rod bearing half, connecting rod

side, trimetallic and dark in colour;

Q

lower connecting rod bearing half, cap side

bimetallic, light coloured with a hole.

Q

Never reverse the positioning of the connecting rod

bearing halves under any circumstances.

5. Rotate the engine through 180º on the overhauled

stand.