ENGINE 1.3L QUADRAJET (90PS)

66

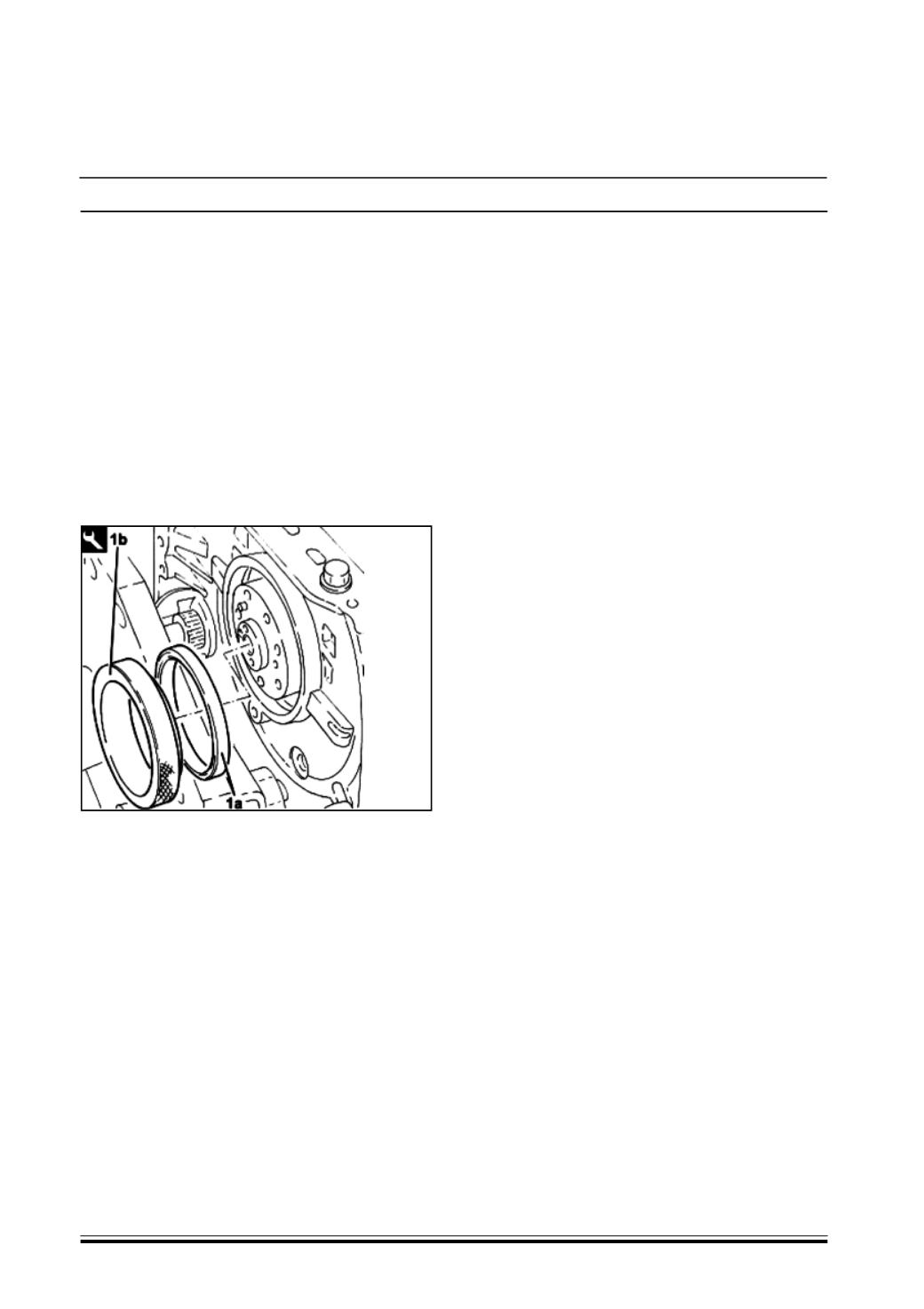

10. Use an appropriate graduated measuring tool (1a)

to measure the clearance indicated by the plastic

gage (1b). The clearance should bewithin the limits

of 0.030 mm ~ 0.062 mm.

NOTE :

Q

Check one journal at a time, without rotating the

crankshaft.

Q

If the clearance is outside of the tolerance, replace

the connecting rod half-bearings with ones of the

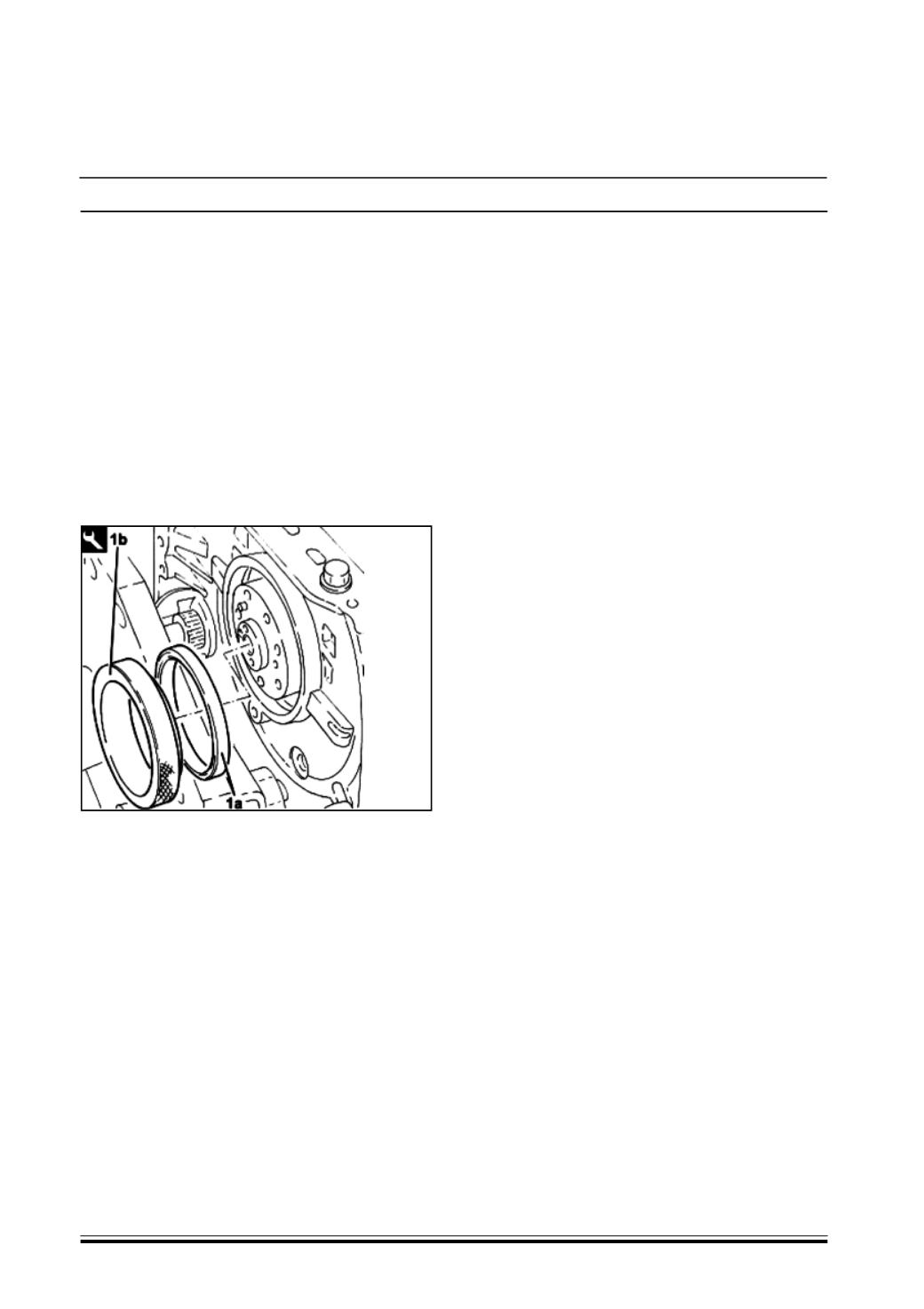

correct size and category.

11. Fit the connecting rod caps permanently by

tightening the bolts as shown previously.

12. Remove the

tool 287158900628 (Flange).

13. Fit the crankshaft rear oil seal (1a) using the

tool

(1b) 287158900670 (Fitting Tool).

14. Rotate the engine through 180° on the overhaul

stand.

15. Place the starter motor in its housing and secure

it tightening the M8 bolts to the recommended

torque of 2.25 ~ 2.75 Kg-m

16. Place the separator condensed oil manifold in its

housing and secure it by tightening the M6 bolts

to the recommended torque of 0.8 ~ 1.0 Kg-m .

17. Place the vacuum reservoir back in it using the

bolt.

18. Place the alternator mounting in its housing and

secure it tightening the (M8 x 1.25 x 45) bolts to

the recommended torque of 2.0 ~ 2.2 kg-m

19. Place the alternator in position and secure it

tightening the (M8x1,25x85) bolts to the

recommended torque of 2.0 ~ 2.2 Kg-m.

20. Place the power steering pump in its housing and

tighten the bolts.

21. Refit the engine oil pipe in its seat on the

crankcase and secure with the connectors.

22. Place the air conditioner compressor mounting in

its housing and secure it tightening the

(M8x1,25x35) bolts to the recommended torque

of 2.0 ~ 2.4 Kg-m.

23. Place the air conditioning compressor in its

housing and secure it tightening the (M8x1, 25x80)

bolts to the recommended torque of 2.0 ~ 2.4 Kg-

m.

24. Replace the engine oil filter mounting complete

with the engine oil filter and engine oil filler fitting

and secure by tightening the M6 bolts to the

specified torque of 0.8 ~ 1.0 Kg-m.

NOTE :

Q

Ensure the gasket is present, undamaged and

correctly positioned.

25. Place the water pump rigid inlet pipe, complete

with O-ring in position and secure it using the bolts.

NOTE :

Q

Fit the rigid pipe in the crankcase very carefully to

ensure the O-ring is correctly positioned.

26. Place the rpm sensor in its housing and secure it

by tightening the M6 bolt to the recommended

torque of 0.8 ~ 1.0 Kg-m .

27. Fit the engine oil heat exchanger protection.