STEERING

17

7.3.3.2 INSPECTION OF DISMANTLED PARTS

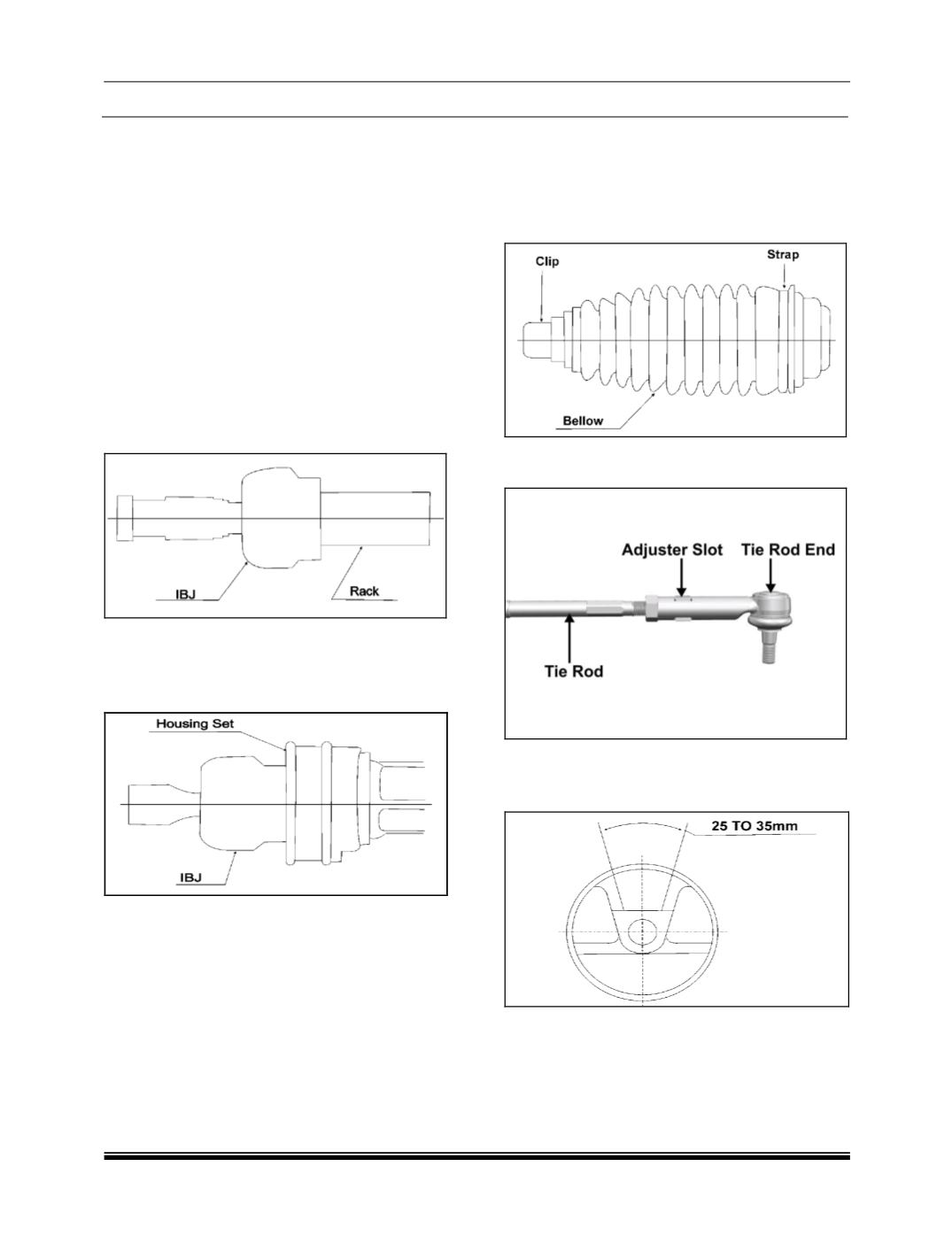

1. Examine Inner Ball Joints and Outer Ball joints

for service failures (any play discard level

more than 0.1 mm at 100 g). If damage to the

joints is evident, replace the parts.

2. In case of accident vehicle and also during

regular overhaul the Rack, Pinion and

Housing set should be checked for visual

cracks, breakage and bend. Check Rack and

Pinion for micro cracks. If any one of the

above is evident, replace the parts.

7.3.3.3 ASSEMBLY OF RACK & PINON

1. Assemble the IBJs on one side. During

assembly, apply loctite 542 (or any thread

sealant) and tighten the IBJs to the required

torque.

2. Smear the Shell sterak grease on rack on outer

diameter and on the tooth root and surfaces.

3. Insert the Rack with IBJ into the Housing set via

Housing.

4. Assemble the Inner ball joint to the outer end of

Rack and secure it against Rack to specified

torque. Follow the same procedure to tighten

IBJ as mentioned in step 2.

5. Assemble the Bellow on the Housing side and

secure the bellow with Bellow strap and Bellow

clip as shown in the fig. Scoop Sili- con grease

using Forefinger and apply on groove of IBJ

prior to the Bellow assembly, to enable bel- low

to rotate relative to IBJ.

6. Fit the Outer Ball joints on either side of inner

Ball joints.

7. Check the free play of the gear at steering

wheel side. (No tyre movement when steering

wheel is turned).