1.05L REVOTORQ ENGINE

64

22. If connecting rod big end parent bore

dimension is maintained within specified

limits, proper bearing bore dimension is

automatically achieved.

23. However, it must be physically measured and

confirmed. Measure pretension of connecting

rod bearing shell with a feeler gauge after

loosening connecting rod bearing cap

mounting nut on opposite side of bearing shell

lug.

Pretension Gap: 0.120 to 0.180 mm.

NOTE

Connecting rod bearing shells are precision

finished and should not be bored or

scraped.

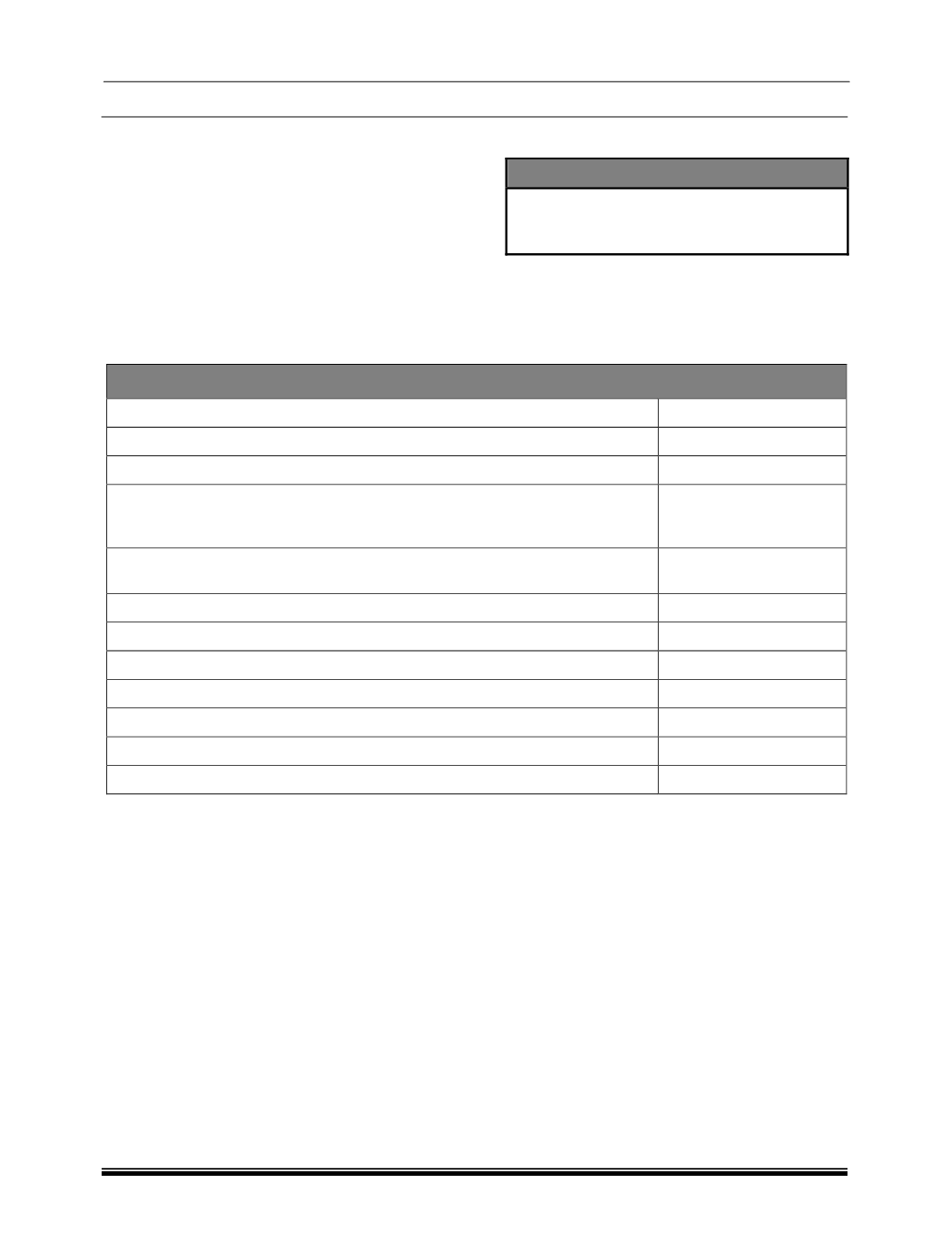

Maintenance Limit

Maximum permissible taper and ovality of connecting rod

0.004 mm

Small end parent bore cylindricity

0.008 mm

Connecting rod small end bush inside diameter (finished after installation)

26.276 - 26.428 mm

Maximum permissible out of parallelism (bend) between connecting rod small

end and big end parent bores, measured at a distance of 50 mm from centre

line of connecting rod.

0.030 mm

Center to center distance between connecting rod small end and big end

parent bores

127.0 ± 0.05 mm

Maximum permissible twist of connecting rod

0.050 mm

Connecting rod big end parent bore diameter

48.655 - 48.671 mm

Big end parent bore and cylindricity

0.01 mm

Bearing shell to be selected such that clearance is maintained as

0.012 - 0.063 mm

Crush height of connecting rod big end bearing shells

0.013 - 0.051 mm

Maximum permissible difference in weight of connecting rods

3 gms

Connecting rod big end axial play

0.8 - 1.2