Revotron 1.2T

114

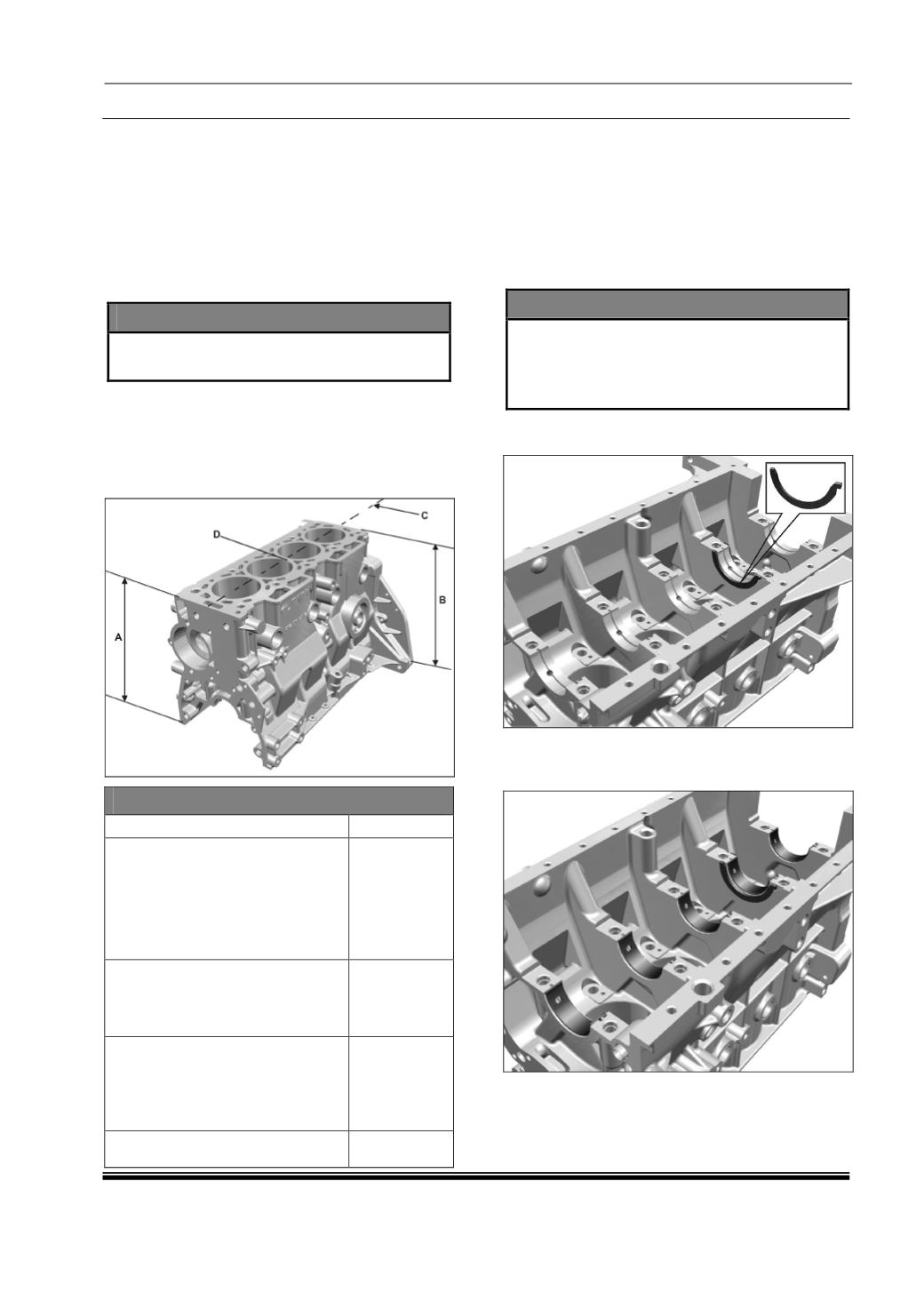

iii. Fitment of Cylinder Block Sub-Assemblies

Cylinder Block

1. Check cylinder block for cracks by pressure

testing method. Clean cylinder bores, bearing

surfaces, oil passages in crank case

thoroughly. Check water jackets for leakages

by blowing air at a pressure of 5 bar & then

dipping the cylinder block in the hot water.

(Temp of water 70

0

to 80

0

C)

NOTE

•

The block with any leakages / cracks

should be discarded.

2. Check crankcase mating surfaces with

cylinder head for unevenness with the help of

straight edge and feeler gauge. If necessary

grind this surfaces just to clear unevenness.

Measure across the length and breadth to

specific mention value in table.

Dimension (mm)

Height of cylinder block (A & B)

265.8/265.6

Maximum permissible

unevenness of cylinder block

case mating surface with

cylinder head 150 X 150

Cross wise (D)

Length wise (C)

0.015

0.030

Maximum permissible out of

parallelism between crank case

top and bottom machined

surface.

0.2

Maximum permissible shift in

perpendicularity of cylinder bore

from crank shaft axis when

checked from crank shaft center

line

0.25

Maximum permissible taper and

sphericity of cylinder bore

0.007

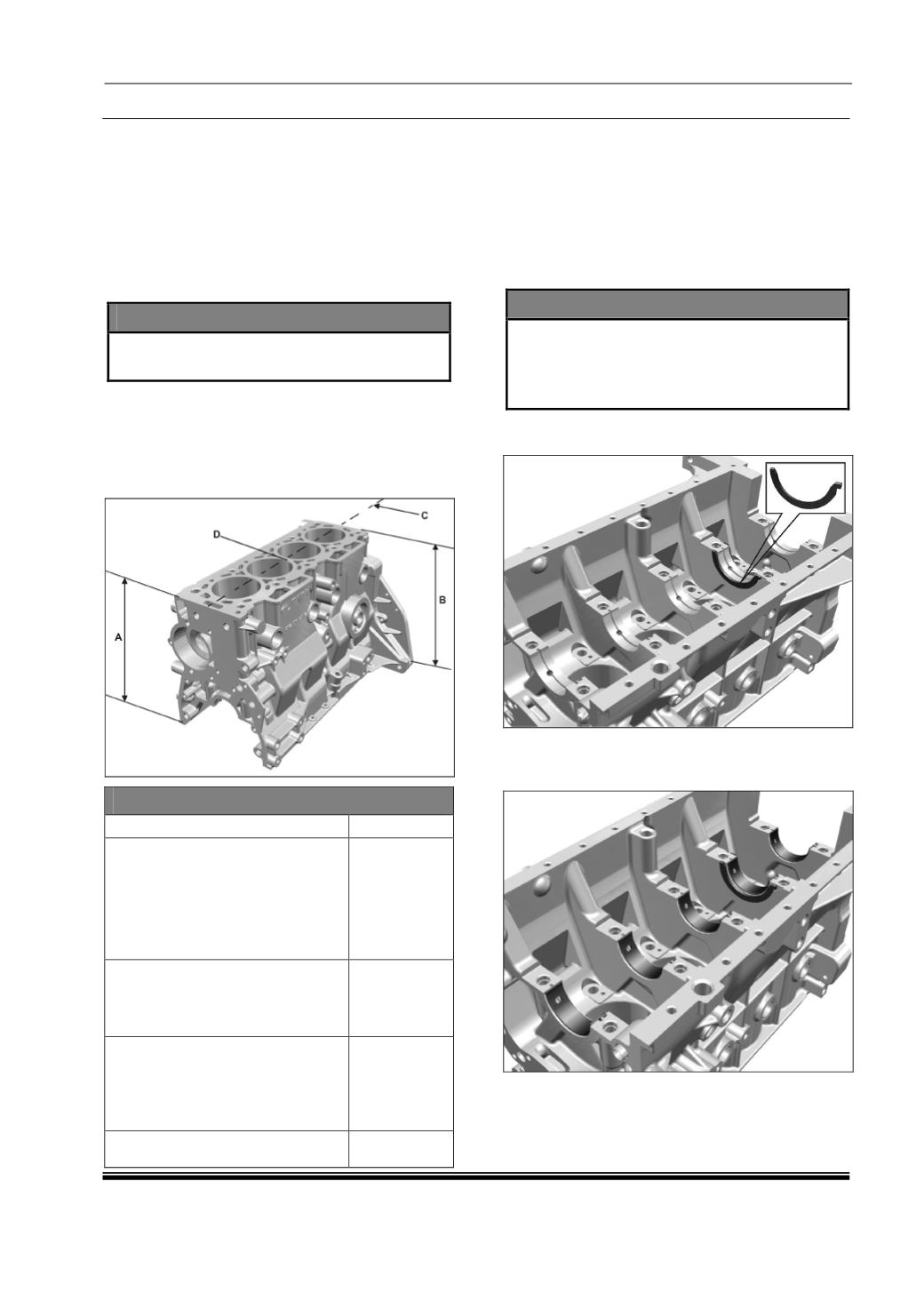

3. Ensure main bearing parent bore dimensions

are within specified limits. (For specified limit

and procedure refer cylinder block inspection

chapter.)

4. Ensure that the minimum height of crank case

is not less than the specified minimum height.

NOTE

•

Apply light coat of grease to the fourth

main bearing cap.

•

Ensure the slot on thrust washers are

facing on outer side.

5. Install thrust washers in crankcase at their

respective locations on 4

th

main bearing.

6. Place lower bearing shells and ensure the

locking slot on bearing shells are properly

fitted.