BRAKES

24

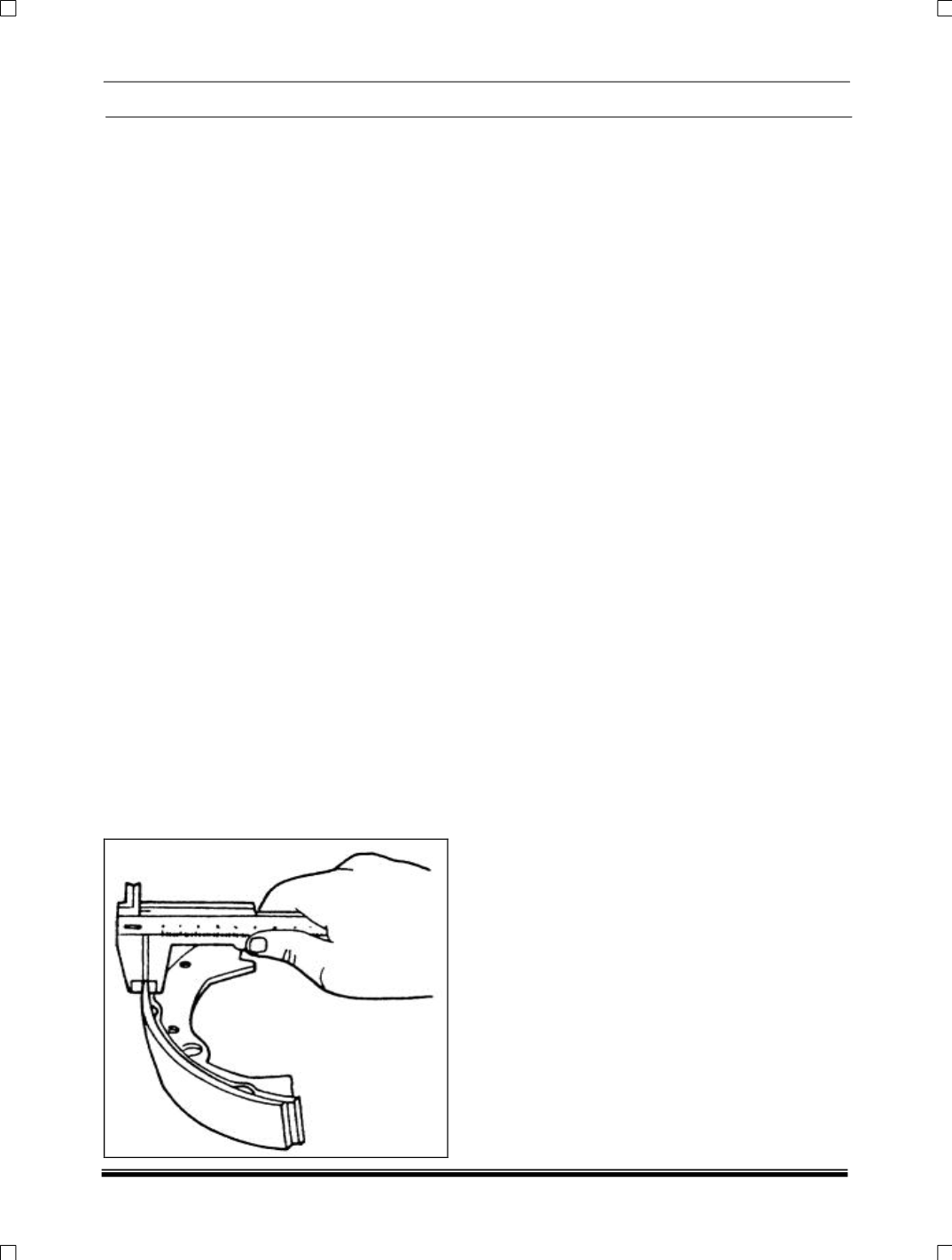

Whenever brake drums are removed, they should

be thoroughly cleaned and inspected for cracks,

scores, deep groove etc. Visual inspection of

wheel cylinder for brake fluid leakage is to be

performed. Drum to be discarded, if found

cracked, scored badly or grooved. Do not to weld

a cracked drum. It is unsafe and must be

replaced.

Smooth up any slight scores, Heavy or extensive

scoring will cause excessive brake lining wear

and it will be necessary to resurface drum-braking

surface. If brake linings are slightly worn and

drum is grooved, drum should be polished with

fine emery cloth but should not be turned.

INSPECT BRAKE SHOE / LINING:

To maintain the efficiency of the brake system,

preventive maintenance is essential.

At specified interval remove the brake drum and

check the lining for wear. The lining must not be

allowed to wear down below 1 mm from rim

surface. Increased foot pedal travel and hand

brake lever movement is an indication that

automatic adjustment mechanism has reached its

end.

The lining shoes need replacement in pair on both

sides of the axle. Always fit new shoe return

spring when fitting new shoe.

Do not polish lining with sandpaper or emery

paper. If lining is polished with sandpaper or

emery, hard particles of sandpaper will be

deposited on the lining resulting in damage of

drum surface.

Whenever lining is to be corrected, replace it with

the new one. Always use genuine grade of

service replacement lined shoes. Do not

contaminate the lining surface with oil or grease.

OVERHAULING OF WHEEL CYLINDER

Overhaul the wheel cylinder at specified interval.

In any case, after a specified interval, the wheel

cylinder should be replaced. The wheel cylinder

may be serviced using parts from appropriate

repair kit, provided the plunger and the bore are in

good condition without any damage.

INSPECTION OF WHEEL CYLINDER

Examine the wheel cylinder bore and the piston. If

they are not scored, corroded or ridged and are

smooth to touch, new seals can be fitted. If there

is any doubt about the condition of the bore, a

new cylinder must be installed.

Inspect the wheel cylinder dust cover for cuts,

cracks, hardening or other sign of deterioration. If

in doubt, replace the dust cover. If the system has

been contaminated with mineral oil of any type,

the system should be flushed out with fresh brake

fluid or alcohol and all rubber parts including

hoses should be replaced.