BRAKES

21

6.10 MAINTENANCE, ADJUSTMENTS & TEST

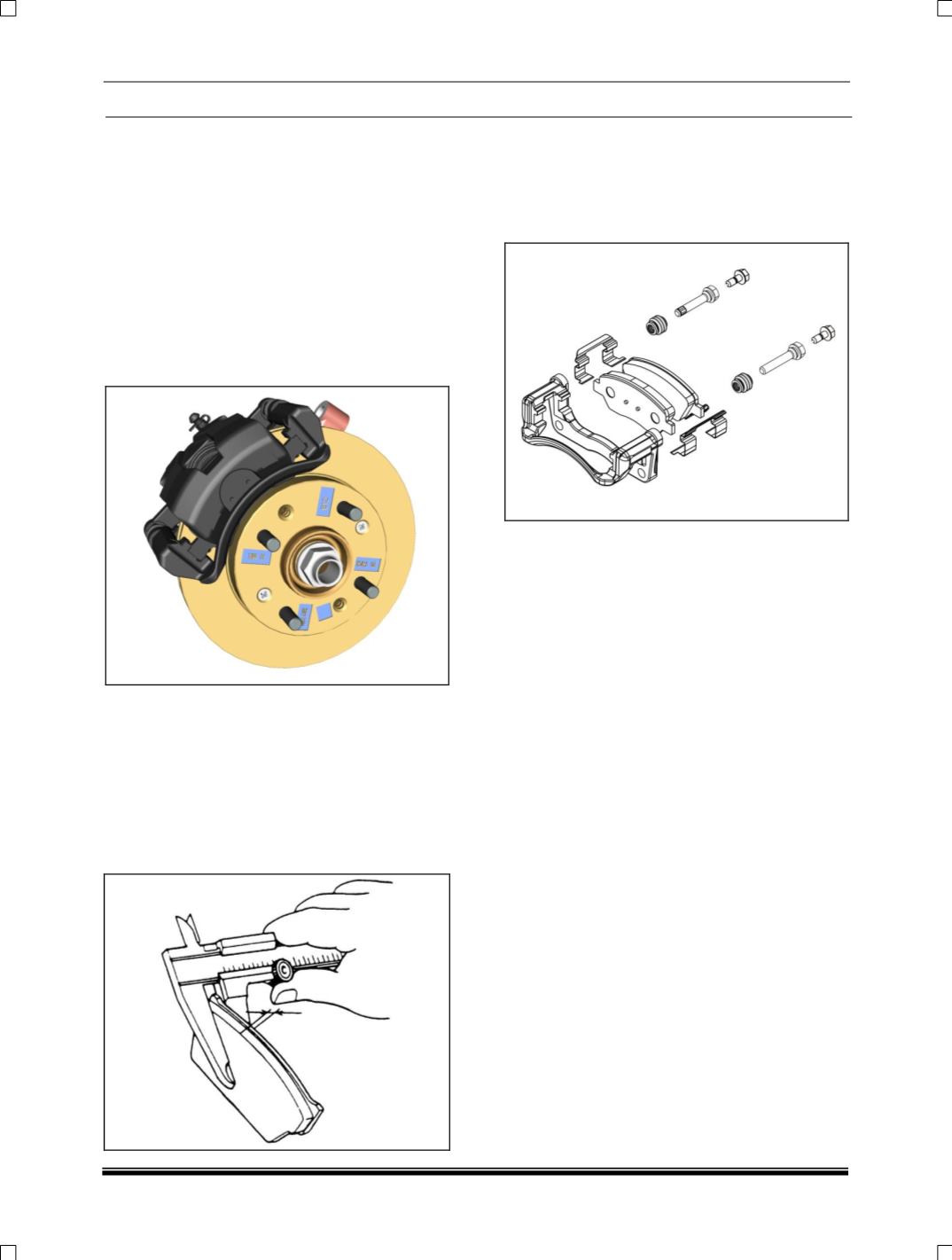

6.10.1 FRONT BRAKE MAINTENANCE

To maintain the efficiency of brakes, preventive

maintenance is essential.

Check the pads for wear at specified interval

given in service schedule. Fit new pads when

lining and metal pad thickness measured together

is less than 6 mm or less. Caliper should be

overhauled at specified interval. Front pads to be

replaced as axle sets only. Do not contaminate

the pads with oil or grease

(Front brake complete assembly)

INSPECTION OF PADS:

Measure pad thickness (with lining) with a Vernier

and if the thickness is found less than 6mm

anywhere in the pad, then it should be replaced

them.

Do not polish pads with sand paper or emery

paper. If the pads are polished with emery or

sandpaper, hard particles of sandpaper will be

deposited in pad and may damage disc.

Front Caliper

1. Whenever pads require correction, replace it

with new one.

2. Always use genuine grade of pad. Do not

contaminate the pad surface with grease or oil.

3. Thoroughly clean the disc. If it is scored badly,

replacement of new pads alone do not give

optimum performance and service life. Hence

follow instructions as given in recondition the

disc.

4. If there is no visible deterioration in piston boot

guide (10) and guide rod (8), new pads can be

fitted.

5. Check for the condition of the spring pad (12)

and if found without any damage the same

clips can be fitted after cleaning. (It is

recommended to replace the Anti-rattle clips at

every Pad replacement. Lubricate the Sliding

pins with the Approved grade of Sliding pin

Grease. The Sliding pins to be lubricated at

specified interval.