BRAKES

19

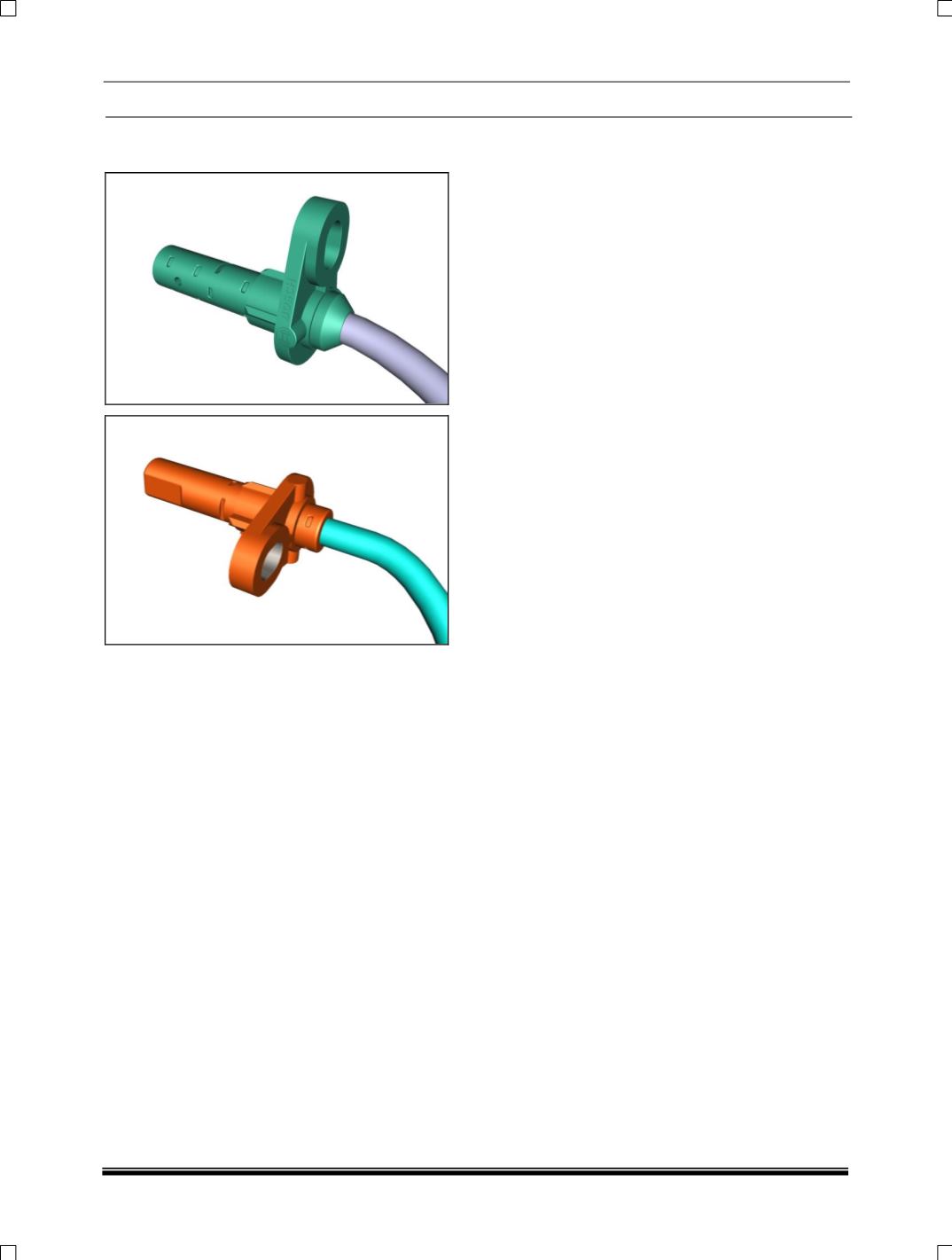

6.9.3 WHEEL SPEED SENSOR: (MONITORS

WHEEL SPEED)

Working principle:

It is an active wheel speed sensor, which means

that it must be connected to a voltage source for

operation. It supplies a signal with constant

amplitude pulses whose frequency varies with the

wheel speed. It uses Hall Effect principle, it has a

semiconductor chip with the electronic circuitry for

supply and signal processing integrated on it.

This chip is located within a completely insulated

magnetic circuit consisting of permanent mag- net

and pole elements. The wheel speed sensor is

mounted directly above the magnetized toner

wheel

The magnetized toner wheel is a ring with teeth

on it. The toner wheel is fitted on to the wheel

hub. The alternating teeth and gap that

accompanies the wheel rotation induces

differential magnetic flux density, thus leading to

the variation in the voltage induced in the

semiconductor chip. The signal conditioning

circuit converts this voltage variation into constant

amplitude current pulses. The frequency of these

pulses de- pends up on the wheel speed. This

measurement principle permits zero speed

measurement.

Precise alignment and gap (1 mm) between the

stator pole and the Toner wheel is vital. To obtain

correct signal, the specified gap between the end

of sensor & the toner ring must be maintained.

Front

: 0.5 mm to 1.5 mm

Rear

: 0.1 mm to 1.4mm

Precautions while handling wheel speed

sensor

1. Storage temperature (- 40°C to + 115°C)

should not be exceeded

2. Avoid free fall of the sensor

3. The sensor tip should not be scratched.

4. Sensor should not be exposed to strong

magnetic field.