BRAKES

23

DISC INSPECTION:

The disc should be free from score marks. If

scored, it should be ground and refitted. Do not

grind the disc more than 0.25mm per side. If the

total thickness of the disc after grinding is found to

be less than disc discard thickness of 20 mm, the

disc should be changed.

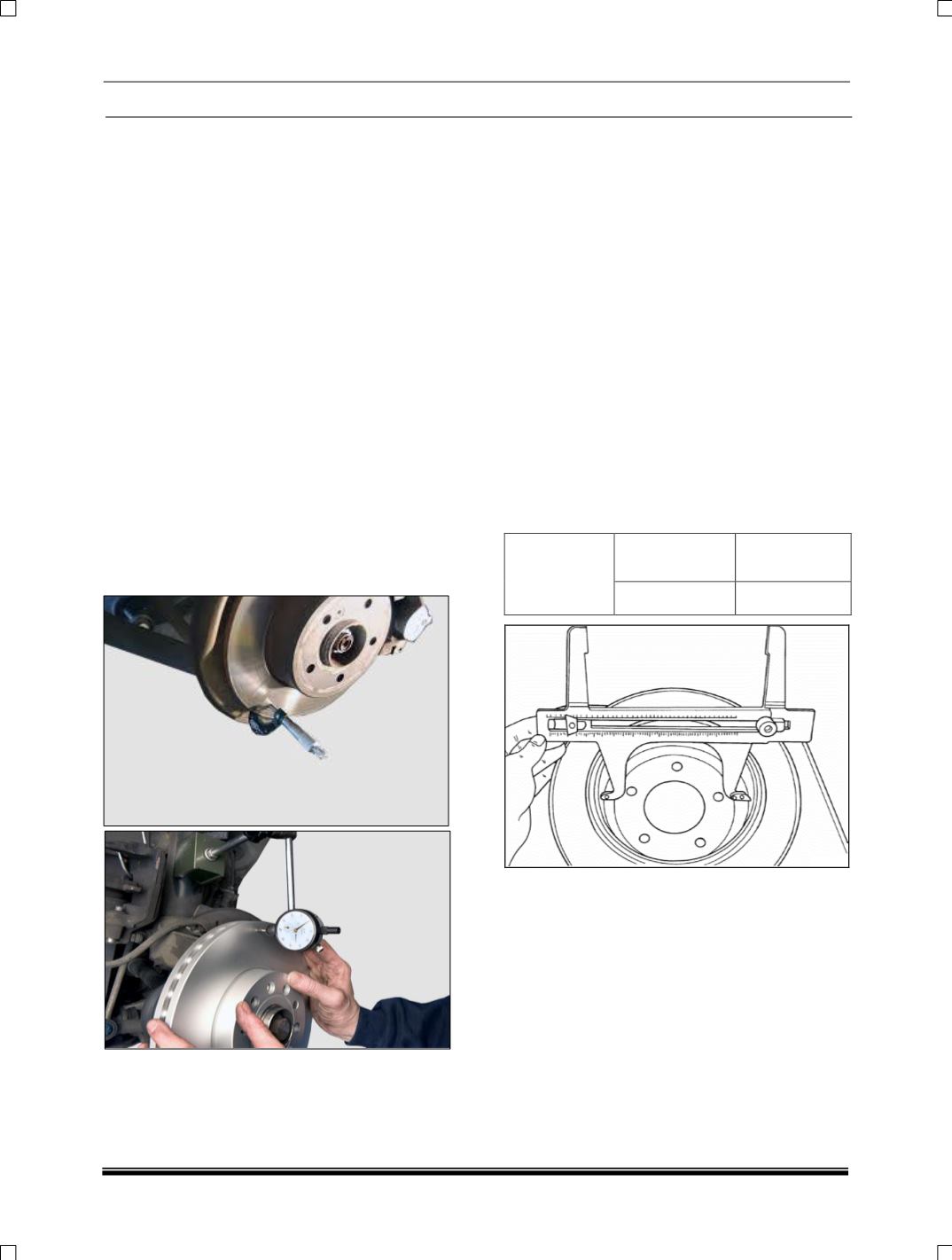

The disc thickness variation is to be checked by

measuring the thickness of the rotor at four or

more points around the circumference of the rotor.

All measurements must be made at the same

distance from the edge of the rotor.

After fitment, the face runout of the disc should be

less than 0.03 mm.

During measurement confirm the dial gauge

probe should be approx. 10 mm from the outer

edge of the brake rotor, perpendicular to the disc

and under slight preload.

Check front wheel bearing for looseness before

face runout measurement.

The control of the braking surface finish is

necessary to avoid pulls and erratic performance.

It will also helps in extending pad life.

6.10.2 REAR BRAKE MAINTENANCE

:

To maintain the efficiency of the brake system,

preventive maintenance is essential and the

following recommendations should be observed at

the intervals stated.

1. At specified interval remove the brake drums

and check the lining for wear. The linings

should not be allowed to wear less than 1 mm

from the shoe rim.

2. At specified interval clean the back plate and

lubricate the tips of the shoe platforms and the

moving parts of the adjuster. Keep the grease

away from the shoe linings and all hydraulic

parts.

BRAKE HOSES

Replace Brake hoses at specified interval.

DRUM INSPECTION:

Inspect the drum for cleanliness. Check for crack,

scores etc. Check braking surface for its wear by

measuring the inside diameter.

Brake drum

inside dia.

Standard

Service limit

200

202