SUSPENSION

49

5.10.6. BALANCING WHEELS:

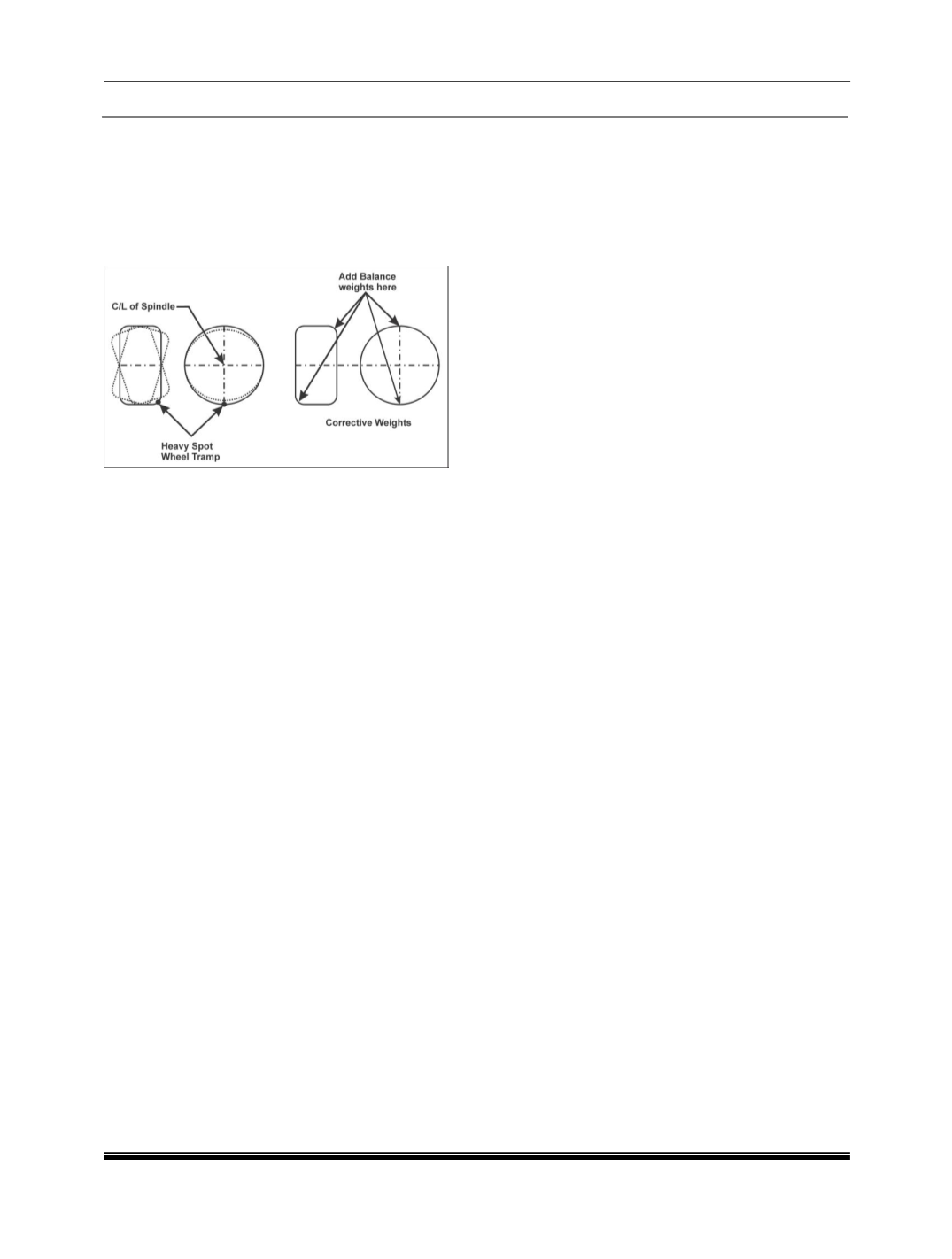

Dynamic balance, as shown in fig 90 is the equal

distribution of weight of each side of the wheel

center line so that when the tyre spins there is no

tendency for the assembly to move from side to

side. Wheels that are dynamically unbalanced may

cause shimmy.

FIG. 90

GENERAL BALANCE PROCEDURES:

Deposits of mud, etc. must be cleaned from inside

of rim.

WARNING:

Remove stones from tread, clean the tyre and rim

before balancing for safety to achieve better

results.

Each tyre should be inspected for any damage,

and then balanced according to equipment

manufacturer’s recommendation.

OFF-VEHICLE BALANCING:

Most electronic off vehicle balancers are more

accurate than the on-vehicle spin balancers. They

are easy to use and give a dynamic (two plane)

balance. Although they do not correct for drum or

disc unbalance as does on vehicle spin balancing,

this is overcome by their accuracy.

NOTES:-

1.Permissible imbalance for assembly tyre with

rim, 95

gm.cmMax.

2.Relocate the tyre if the weight required to

balance is more than 80 gms (for 13 inch tyre) &

140 gms (for 14 inch tyre).

3.Total balance weight should be within 140 gm on

each side.

4.Donot use more than one balance weight on one

side.

5.10.7. TYRE CARE:

Repairing a Tyre:

Mark the tyre position (if original color dot mark is

not visible) with respect to valve stem hole to

ensure that the tyre is refitted in the original

location on the wheel rim.

Ensure that balancing weights are not disturbed

during removal of tyres.

Check the balance weight prior to the removal of

the tyre. If found loose, mark its location on the rim

& refit properly.

Balance the wheel after every dismantling and

assembly of tyre on the wheel rim.

While fitting wheels on the vehicle ensure that

wheel pins are free from dust, scratches, dirt,

dents, etc.

NOTE:

Do not apply any oil on the wheel pins. Wipe off the

oil if present.

SPECIAL CARE FOR TUBELESS TYRES:

1.While removing tyre from wheel rim and

mounting it back on wheel rim, take precautions

not to damage tyre bead. Use tyre removal and

assembly machines. Damage or cut on tyre bead

may cause gradual loss of air and deflation of

tyre.

2.Donot scratch inside of tubeless tyre with

metallic or sharp object. Tubeless tyres are

coated with impermeable layer of rubber from

inside which holds the air inside the tyre.

Removal of this layer due to scratching may

cause gradual loss of air and deflation.

3.Ifwheel rim gets damaged in service, get the

wheel rim repaired/replaced immediately.

Running the vehicle with damaged rim may

cause deflation of tyre and subsequent

dislodging of tyre from rim.

4.Maintain recommended inflation pressure. Over-

inflation, in particular, may cause puncture or

bursting of tyre.

NOTE:

Life and wear pattern of tyres depends on

various

parameters like tyre pressure, wheel

alignment,

wheel balancing, tyre rotation, etc. It also

largely

depends on vehicle speed, load carried,

usage,

driving habits, road conditions, tyre quality,

etc. In

case fault is suspected to be due to poor

quality of

tyres, the same may be taken up with

concerned

tyre manufacture.