DRIVETRAIN-TA65 Star

19

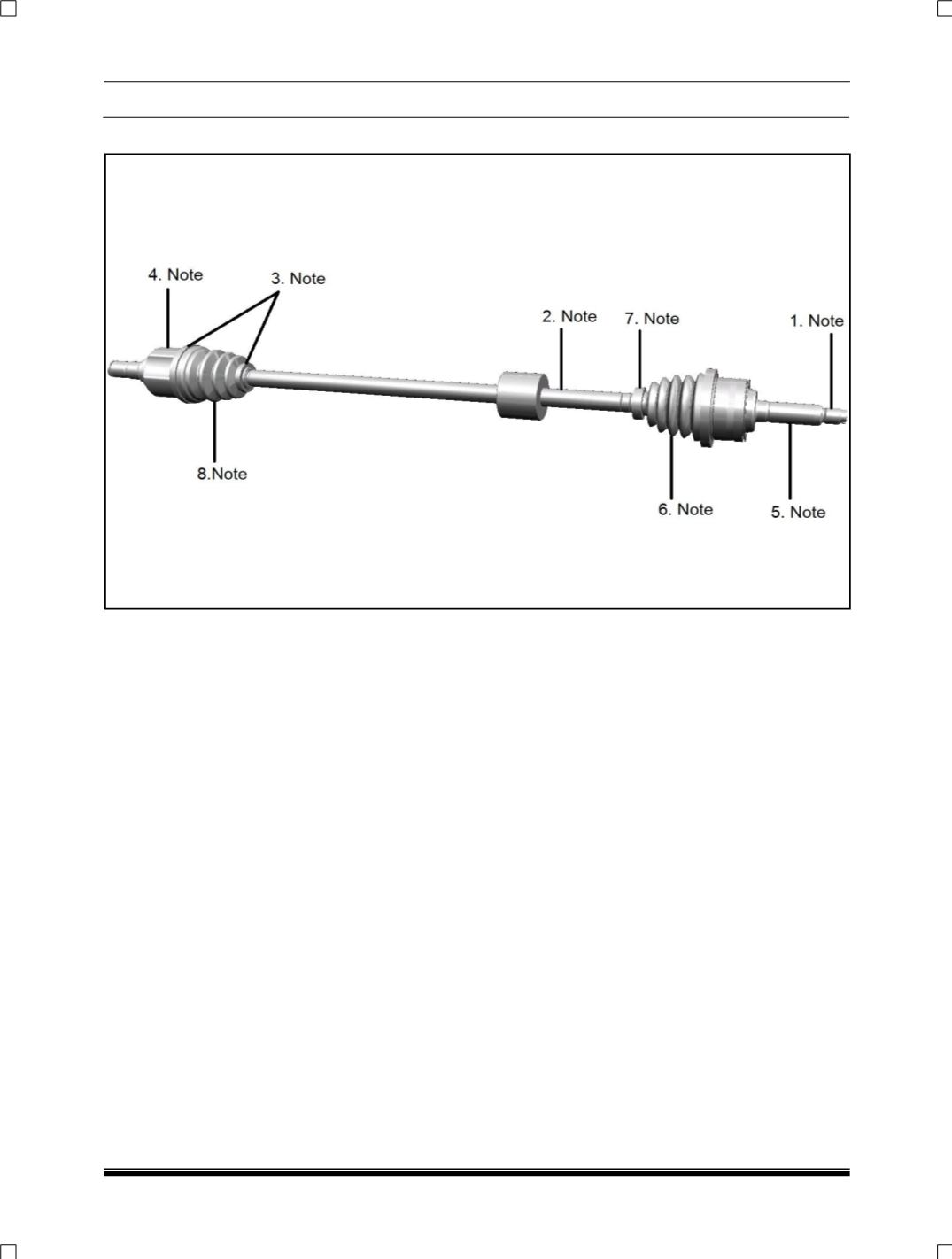

4.5. B. DRIVESHAFT

Fig. 3

Half shafts must be stored in their original shipping

containers or supplier approved fixtures until

assembled into vehicle. It is important to take all

precautions to avoid stacking half shafts on top of

each other. The seals and deflecting rings are

extremely delicate and any cut, nick, or abrasion

may reduce the performance of the driveshaft.

1. Note:

If Out board joint must be angulated to fit

the half shaft assembly into the vehicle,

all precautions should be taken to avoid

damaging the surface of the threads and

splines during installation.

2. Note:

Take all precautions to avoid any contact

between the inboard and outboard seals

and any surface which may cause a cut,

nick or abrasion. The seals are extremely

delicate and critical to the performance to

the half shaft. Do not allow the seals to

contact other half shafts, workbenches,

the vehicle frame, lower control arm, or

any other chassis component. If grease

leakage is observed from either seal, the

half shaft should be removed from the

vehicle, handled with care, and returned

to authorize dealer for analysis.

3. Note:

Clamps should be in position and tight. If

clamps are loose, don’t install into

vehicle.

4. Note:

To prevent damage to the internal

components of the inboard joint, take all

precautions to avoid over extending the

joints.

5. Note:

Protect this surface from nicks and

scratches. Damage to this surface may

reduce the performance of the mating

seal.

6. Note:

Protect deflector ring from impacts, which

could cause dents. A dented/Damaged

deflector ring may result in an

interference condition and affect the seal.

7. Note:

Eared clamp must be in position and

crimped. Take precaution to avoid any

contact between the ear of the clamp and

any object, which may bend/crush, the

“ear”. A damaged “ear” will decrease the

clamping load, which may cause grease

leakage and / or intrusion of water/debris.

8. Note:

Take precaution to avoid any contact

between the inboard seal and the tooling

used to insert the assembly into the

transmission. Contact between the seal

and the tooling will cause a seal peak

abrasion which may reduce the life of the

seal and lead to dissatisfied customer.