DRIVETRAIN-TA65 Star

14

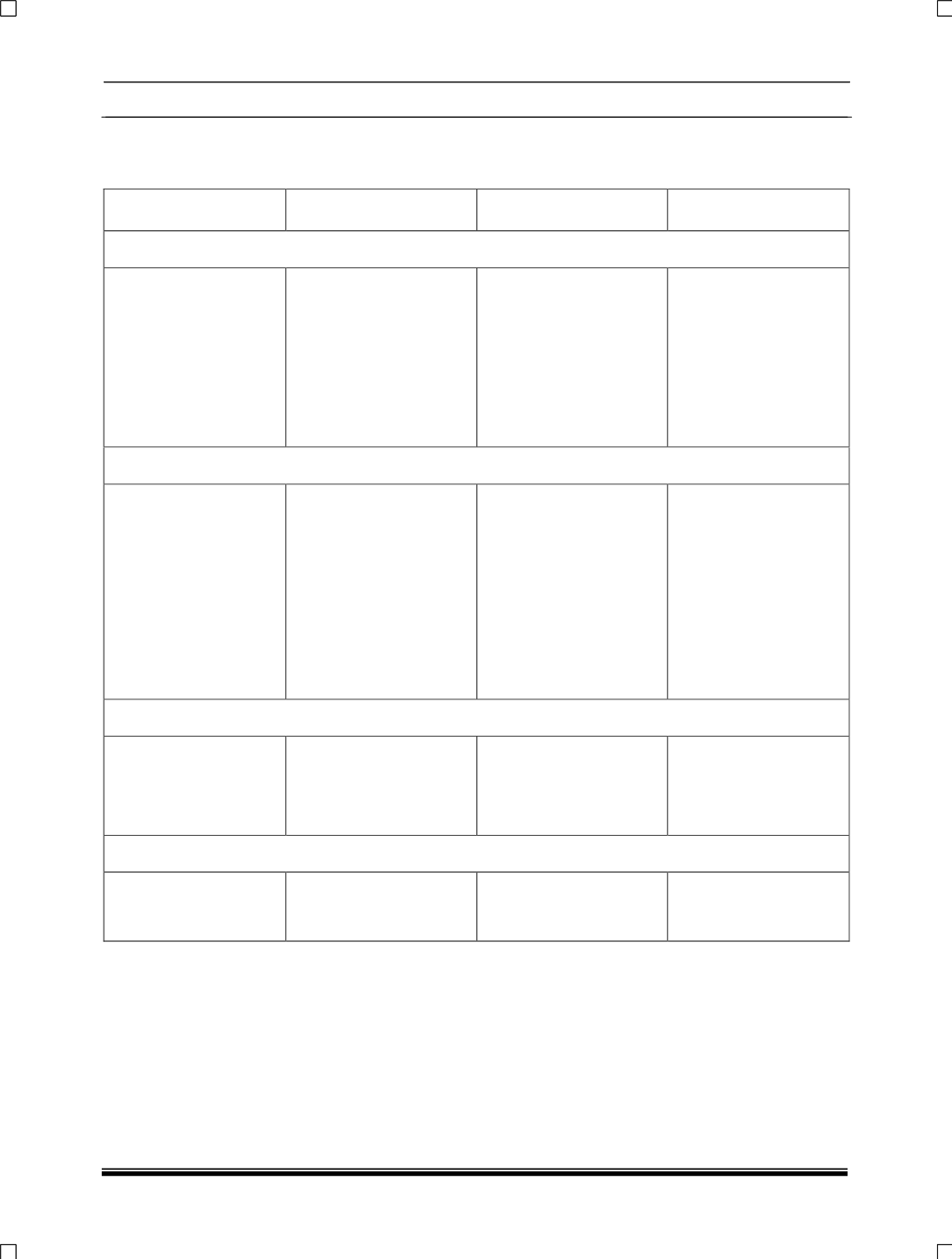

4.4. DIAGNOSIS

4.4. A. DIAGNOSIS OF CLUTCH:

IN THE VEHICLE

THE COMPONENT

CAUSES

REMEDY

1. New Clutch: Difficulty in changing gear

Difficulty in changing

gear,

following

replacement of clutch

shaft.

Burrs thrown up around

splines causing stiff

movement on shaft.

Due to poor alignment of

the

gearbox

on

reassembly.

The driven plate was

improperly aligned.

Aggressive location of

shaft into hub.

Care with the centering

of driven plate; use an

appropriate

clutch

aligning tool.

Do not force the

gearbox but rotate the

flywheel or gearbox

shaft to line up input

with splines.

2. Loss of Drive: With recently fitted clutch

Loss of drive and loud

clatter, only covered a

few hundred kilometers.

The centre hub of the

driven plate has ripped

out and possibly one or

more of the springs have

been pushed out.

The weight of the

gearbox has been hung

on the centre plate. This

has distorted the driven

plate resulting in failure

within a short period of

use.

Very aggressive clutch

control .i.e. “Racing

starts” or when towing a

heavily laden trailer.

Ensure

that

the

gearbox shaft and

gearbox are not hung

on the clutch driver

plate by using a pit jack

or trolley jack to support

the

gearbox

on

reassembly.

3. Slipping Clutch

Clutch slip. The control

system is in good

condition and correctly

adjusted.

The

clutch

friction

material is contaminated

with oil.

There is an oil leak from

the engine or gearbox.

Carefully check the

engine and gearbox oil

seals. Replace seals if

oil is present in bell

housing.

4. Juddering During Pulling Away

Clutch judder on initial

take up of torque.

Oil or grease found on

the middle of clutch to

driven plate.

Excess grease applied

on input shaft splines.

Only use the correct

amount and correct

type of grease.