1.2L REVOTRON ENGINE

71

M. Fuel Tank -:

Inspection:

1. While removing fuel tank, check all hoses and

pipes connected to fuel tank for leaks, loose

connections, deterioration or damage. Replace

if necessary.

2. Check the fuel pump gasket for leaks, cracks,

replace if necessary.

3. Visually inspect fuel tank for leaks and

damage. Replace if necessary.

Fuel Tank Purging Procedure

WARNING

The purging may not remove all fuel

vapours. Therefore any repair on fuel tank

using external heat or flame may result in

explosion causing personal injury or

damage.

4. Remove fuel tank from the vehicle. Refer

procedure as mentioned for fuel tank removal.

2. Remove all fuel lines from fuel tank.

3. Remove fuel pump and fuel level gauge from

fuel tank.

4. Shift the tank to flushing area.

5. Fill tank with warm water or normal tap water

and agitate rigorously and flush out the tank

and.

6. Repeat this procedure until inside of the tank is

clean.

7. Replace the fuel tank if it is rusty from inside.

8. Completely flush out remaining water after

washing.

CAUTION

Do not allow water to remain inside fuel

tank after washing. This will cause

corrosion inside fuel tank. Use shop cotton

cloth for tank cleaning. Do not use cotton

waste.

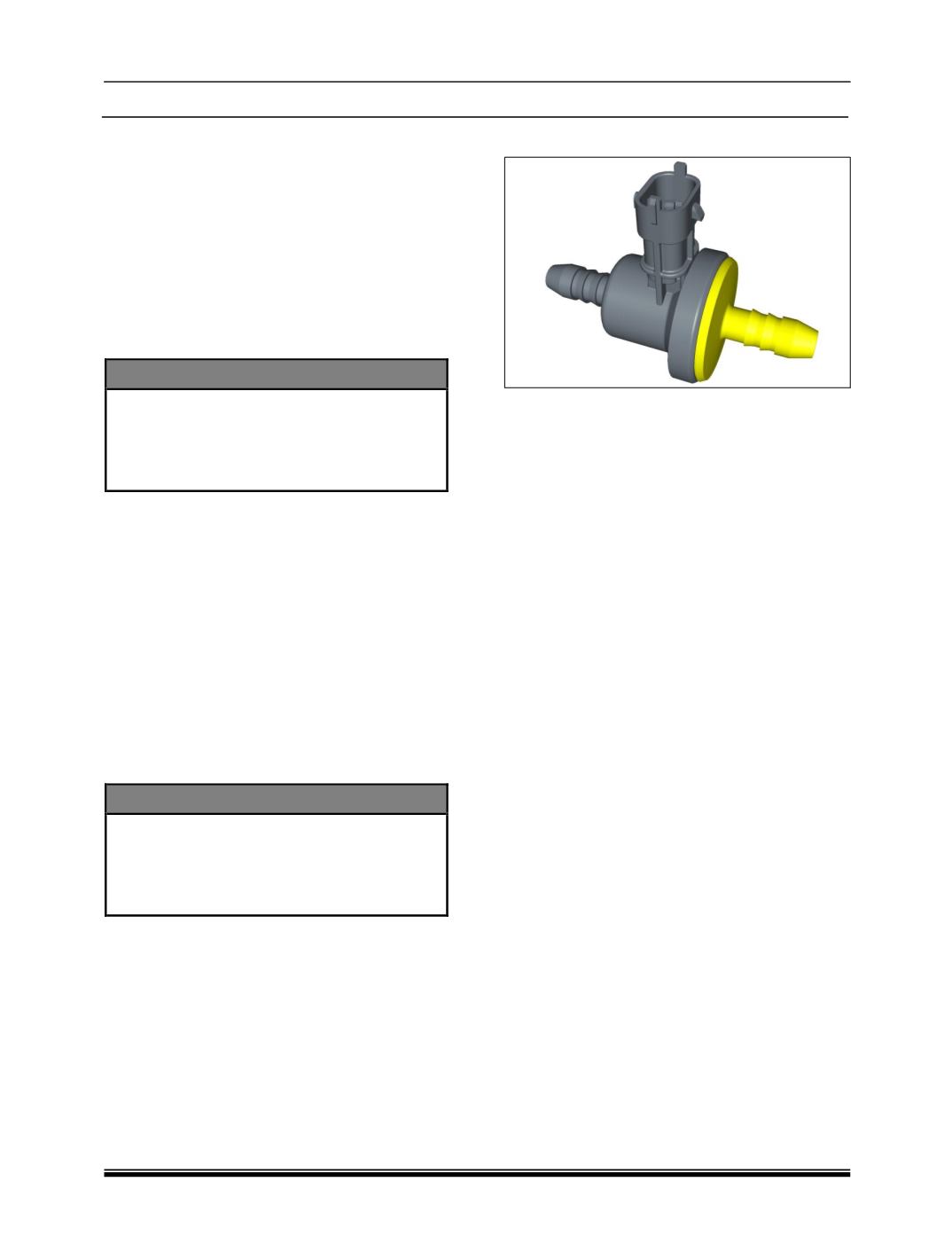

N. Canister Purge Valve

Removal:

1. Disconnect hose from canister purge valve to

T connector.

2. Disconnect the hose from canister to purge

valve from canister “purge” end.

Inspection:

1. With ignition switch OFF, disconnect

connectors from canister purge valve.

2. Check resistance between two terminals of

canister purge valve. Resistance 26 + 4 ohm

at 20C. If resistance is as specified, proceed

to next operation, check. If not, replace.

3. Blow air into hose removed from T connector.

4. Verify that no air flows through the valve

when the engine is stopped with purge valve

connectors disconnected.

5. Air will pass through freely when the 12V

battery voltage is applied to valve connector.

It indicates that the valve is functioning

properly.

If no air flows, replace the valve.

6. Reinstall valve connector.

7. Reconnect vacuum hoses.

Warning:

Do not suck air through purge valve. Fuel vapours

inside valve is harmful.