ENGINE 1.3 QUADRAJET (75PS)

54

46.Fit the caps (1b) on the connecting rods (1a) and

secure them by tightening the M8 bolts (1c) to the

recommended torque of 1.9 ~ 2.1daN m + 40° +/

- 2°.

NOTE :

The connecting rods are pre-set fracture type

and are supplied already fractured by Parts together

with the cap bolts. The connecting rod caps are not

interchangeable because the fracture profile differs from

part to part.

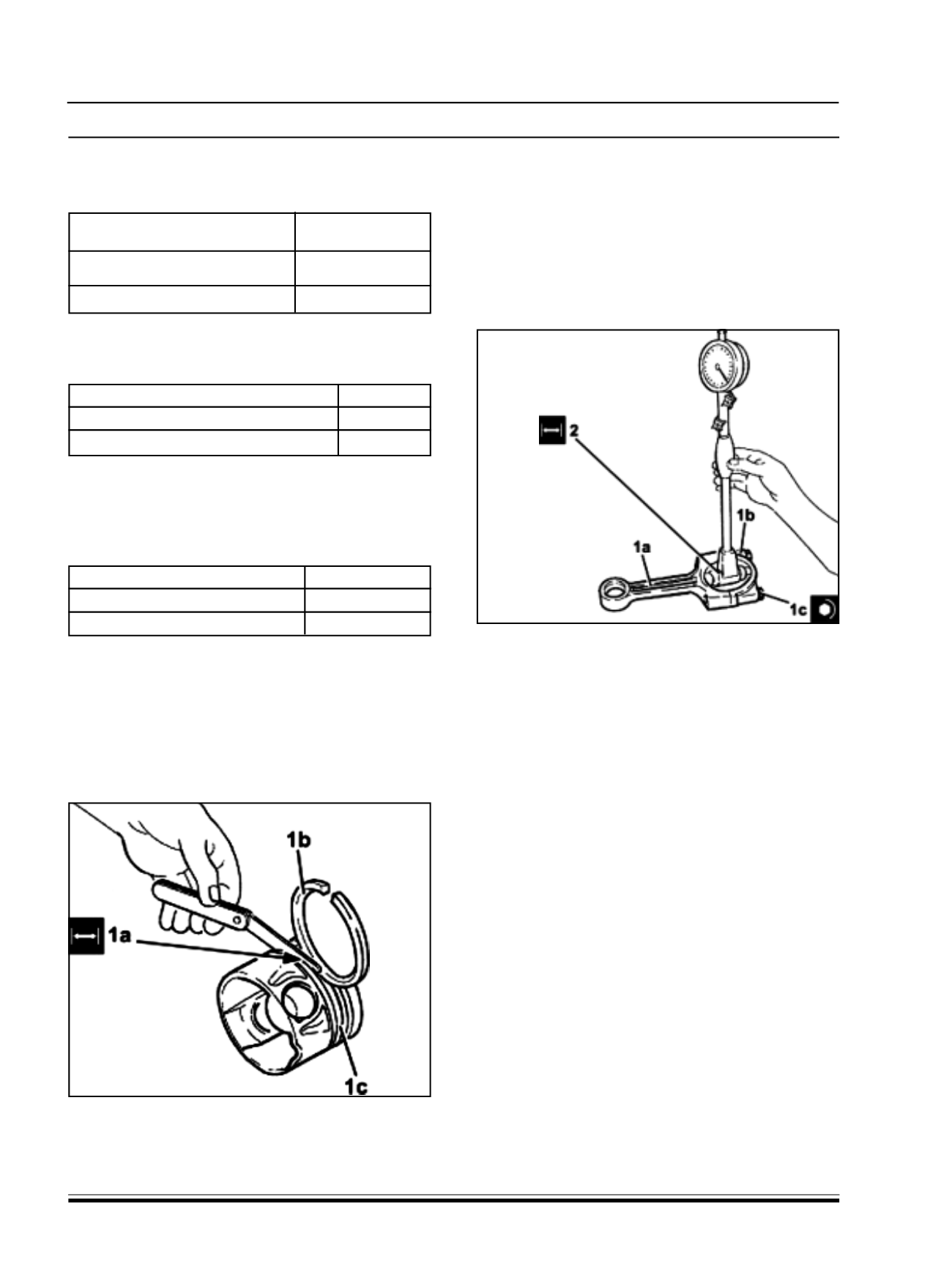

47.Check that the big end diameter (2) (without fitting

the half-bearings) is within the recommended limits

of 45.734 mm ~ 45.744mm; if not, replace the

connecting rods.

48.Check that there are no signs of seizing on the

flywheel ring gear teeth; if this is not the case,

replace it.

49.Refit the engine oil jets in their seats and secure

by tightening the M6 bolts to a torque of 0.8 ~ 1.0

Kg-m .

NOTE :

The crankshaft supplied by the Parts Dept.

40.Check that the thickness of the piston rings is

within the recommended limits.

Cylinder compression 1st sealing

ring thickness (mm)

1.970 ~ 1.995

Cylinder compression 2nd sealing

ring thickness (mm)

1.470 ~ 1.490

Piston oil scraper ring size (mm)

1.970 ~ 1.990

41.Check that the piston ring seats are within the

following recommended values.

Sealing ring seat in piston - 1st groove (mm) 2.08 ~ 2.10

Sealing ring seat in piston - 2nd groove (mm) 1.53 ~ 1.55

Sealing ring seat in piston - 3rd groove (mm) 2.02 ~ 2.04

42 Check that the outer diameter of the pistons

corresponds to the recommended figures; if not,

replace the piston complete with piston rings and

gudgeon pin.

Piston outer diameter - Grade A (mm)

69.520 ~ 69.530

Piston outer diameter - Grade B (mm)

69.530 ~ 69.540

Piston outer diameter - Grade C (mm)

69.540 ~ 69.550

NOTE :

Measure perpendicular to the gudgeon pin axis, 12

mm from the lower edge of the skirt.

43.Check that the axial clearance between the first

ring and the housing in the piston corresponds to

the recommended figures of 0.09 mm ~ 0.13mm.

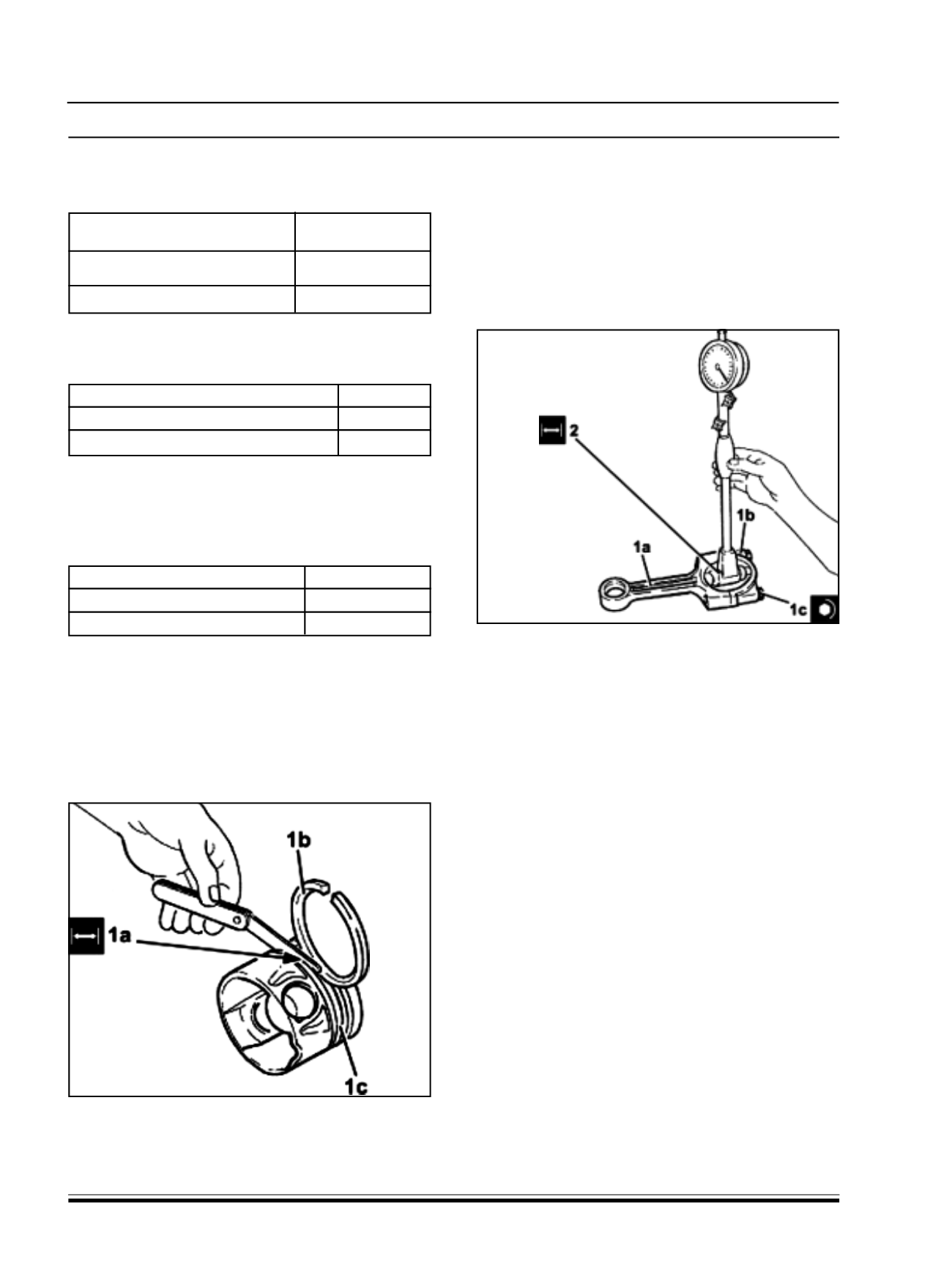

44.Check that the backlash (1a) between the second

ring (1b) and the housing in the piston (1c)

corresponds to the recommended figure of 0.04

mm ~ 0.08 mm.

45 Check that the backlash between the oil scraper

ring and the housing in the piston corresponds to

the recommended figures of 0.030mm ~

0.070mm.

comes without half-bearings and the main journals

and crankpins are the “normal” size; the half-

bearings to be fitted must therefore be selected

identifying the class of each main journal and

crankpin for the new crankshaft.