ENGINE 1.3 QUADRAJET (75PS)

51

3A.1.2.3.4 ENGINE BLOCK – MEASUREMENT,

INSPECTION AND GRADE DETERMINATION

1. Clean sealant residues of f the mating surfaces

between: cylinder head extension/lower cylinder

head, upper crankcase/lower crankcase and

lower crankcase/crankcase sump.

2. Clean the parts removed thoroughly and check

their condition visually.

3. Fit the water/oil sealing plugs in the crankcase

using suitable fitting tools.

4. Lubricate all the mechanical component s with

engine oil.

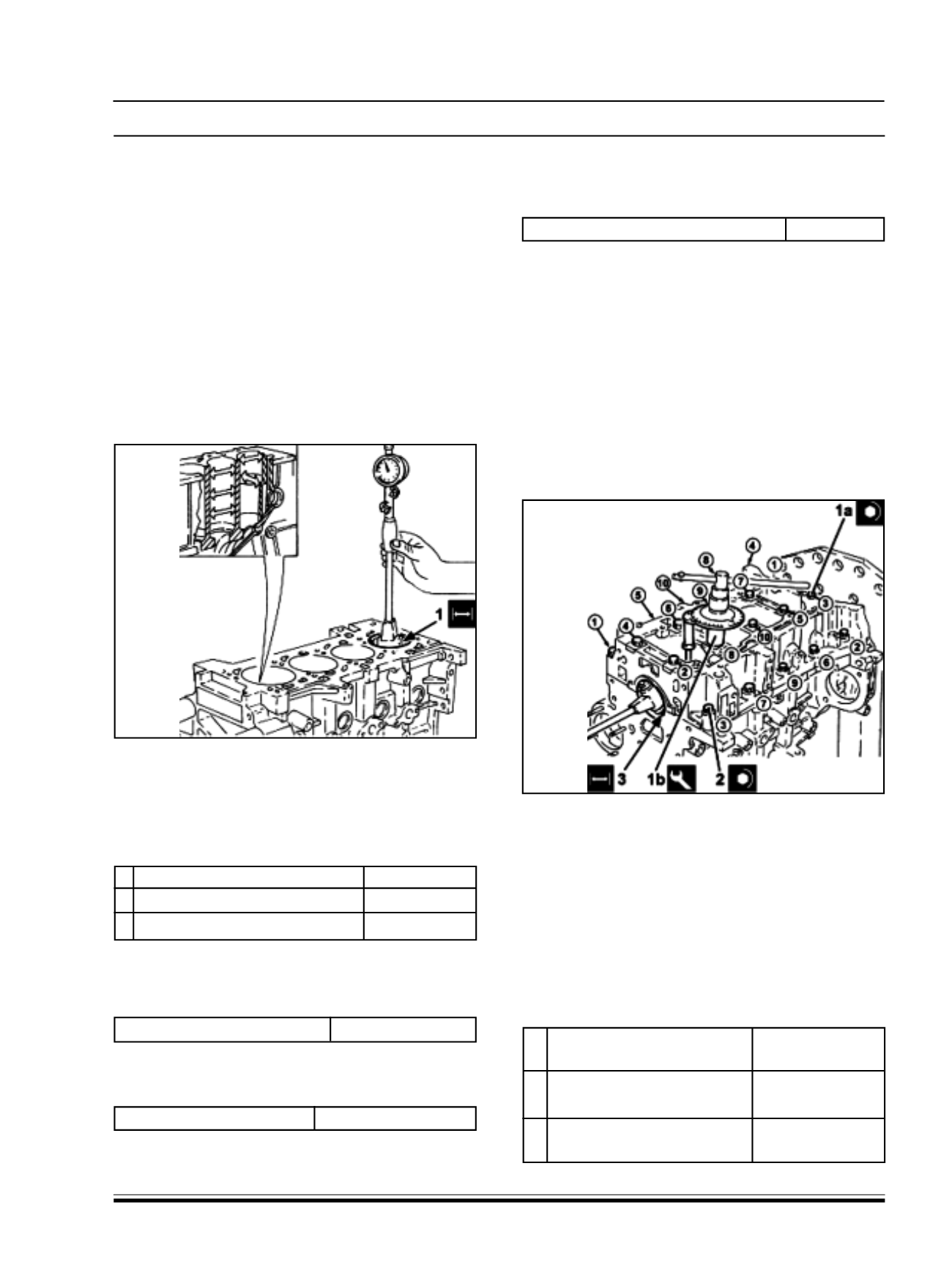

5. Measure the cylinder bore diameter using the

diagram illustrated.

6. Check for the values to be within the

recommended values for the respective grades

as shown below.

1 Cylinder liner diameter - Grade A (mm) 69.600 ~ 69.610

1 Cylinder liner diameter - Grade B (mm) 69.610 ~ 69.620

1 Cylinder liner diameter - Grade C (mm) 69.620 ~ 69.630

7. Check that the taper of the cylinder liners/bores is

within the recommended limit s of lesser than

0.010mm

Cylinder liner taper (mm)

< 0.010

8. Check that the ovality of the cylinder liners is within

the recommended limits.

Cylinder liner ovality (mm)

+/- 0.005

9. If the cylinder bore measurements are not within

the recommended limits, ream the cylinder bores

following the recommended oversize of 0.1mm.

Cylinder liner diameter oversize (mm)

0.1

NOTE :

If reaming is undertaken, ensure that all the bores

have the same oversize.

10 Use an appropriate support tool to replace the

upper crankcase on the overhaul stand.

11 Refit the lower crankcase locating bushes in their

seats.

12 Provisionally fit the lower engine block on the upper

engine block to measure the main journal seat s

and then remove it.

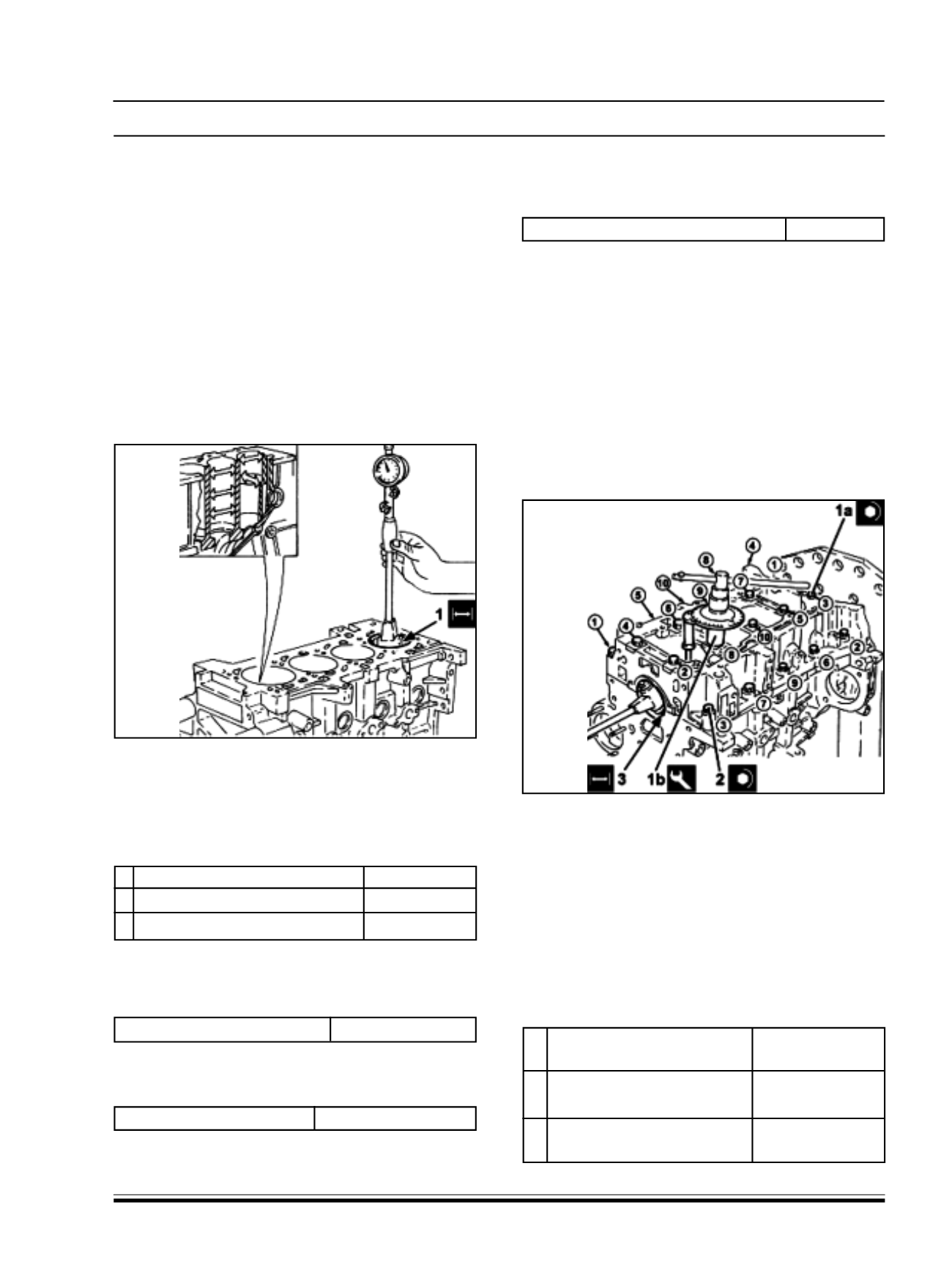

13.Loosen the central M10 bolt s (1a) securing the

lower crankcase to a torque of 1.9 ~ 2.1Kg-m +/-

3

0

, following the order shown in the figure. Use

the angular tightening tool (1b).

14.Tighten the lower crankcase side M8 bolt s to a

torque of 2.9 ~ 3.2 Kg-m, following the order shown

in the figure.

15.Check that the diameter of the main journal seats

is within specified limit s (without fitting the half-

bearings).

3

Main journal seat diameter -

Category A (mm)

54.710 ~ 54.714

3 Main journal seat diameter -

Category B (mm)

54.714 ~ 54.718

3 Main journal seat diameter -

Category C (mm)

54.718 ~ 54.722