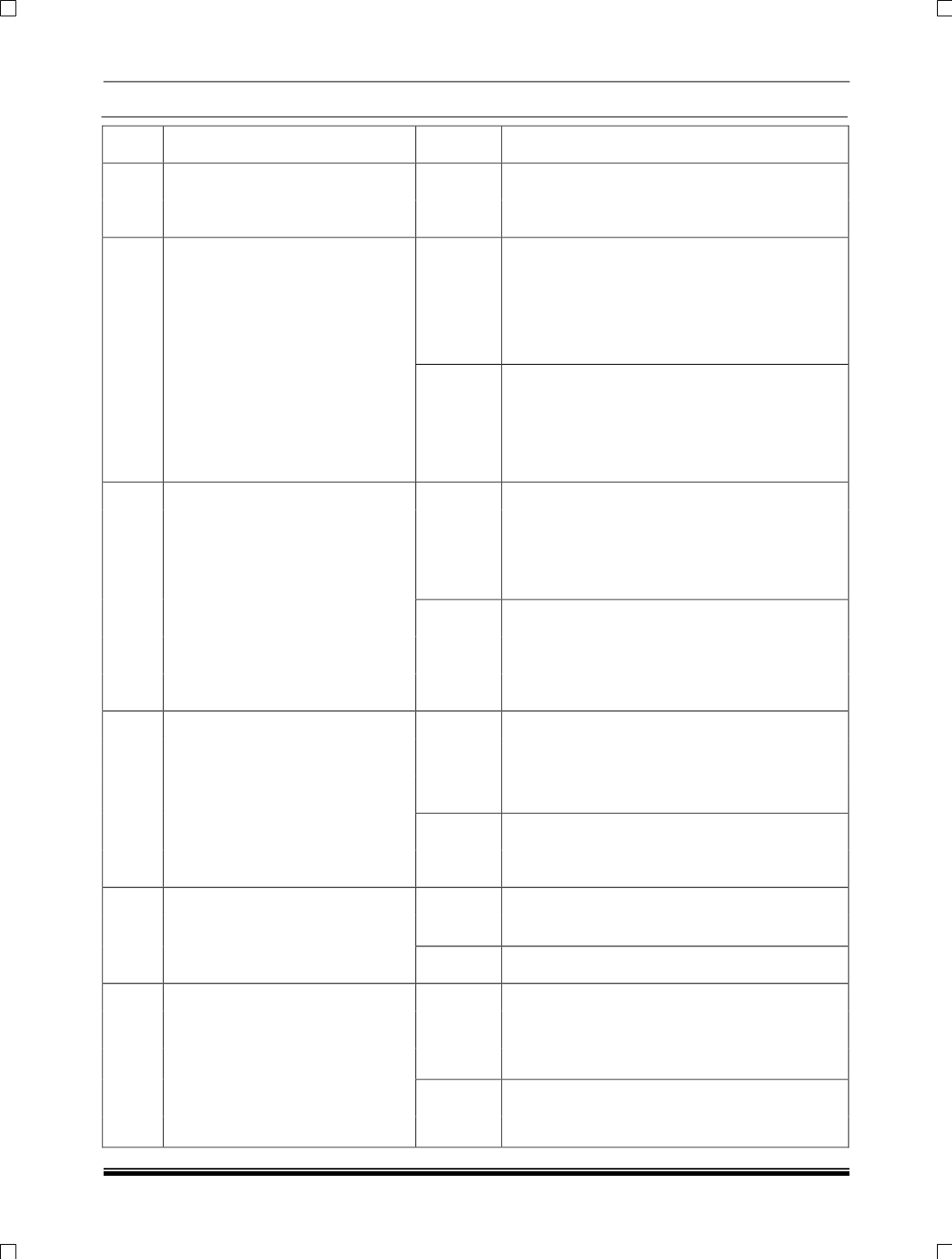

HVAC

31

STEP INSPECTION

ACTION

If there is no damage, go to next step.

12

Inspect evaporator piping connec-

tions in cooling unit for looseness

Yes

Tighten connections to specified torque.

If the vane makes a noise, add 10 ml of compres-

sor oil to the A/C compressor.

Verify that the noise is no longer heard. Adjust

refrigerant to specified amounts.

No

If the vane makes a noise, add 10 ml of compres-

sor oil to the A/C compressor.

Verify that the noise is no longer heard. Replace

O-ring on piping, adjust refrigerant to specified

amounts.

13

Inspect piping connections for

looseness are piping connections

loose?

Yes

Tighten connections to specified torque. If the

vane makes a noise, add 10ml of compressor oil

to the A/C compressor. Verify that the noise is no

longer heard.

Adjust refrigerant to specified amounts.

No

If the vane makes a noise, add 10ml of compres-

sor oil to the A/C compressor.

Verify that the noise is no longer heard. Adjust

refrigerant to specified amounts.

14

Verify whether malfunction is in

expansion valve, air mix and com-

pressor oil or elsewhere does

refrigerant’s high-pressure value

hardly increases?

Yes

Go to next step.

(Pressure hardly increases.)

No

Go to step 17.

5

Verify whether a malfunction is in

compressor oil amount and a/c

compressor or elsewhere when

engine is racing, does high-

pressure value increase?

Yes

Return to step 3.

No

Go to next step

16

Verify whether malfunctions is in

compressor oil amount or a/c com-

pressor after compressor oil is

replenished each 10 ml, does high-

pressure value increase?

Yes

Troubleshooting completed. (Explain to customer

that cause was insufficient compressor oil.)

No

Replace A/C compressor. (Cause is defective AC

compressor)