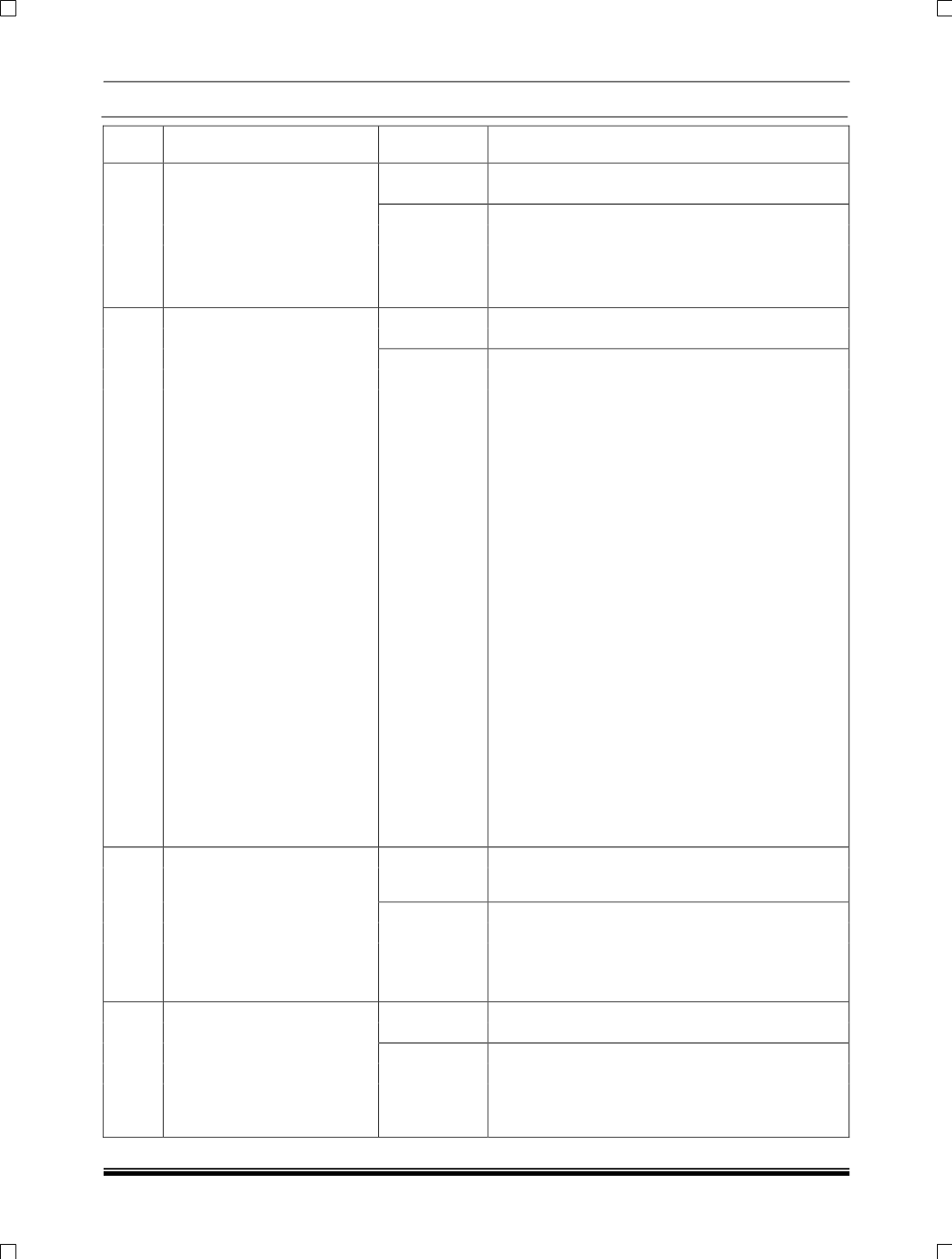

HVAC

35

Step

Inspection

Action

7

Inspect refrigerant amount

Inspect refrigerant amount.

See refrigerant system ser-

vice procedures, refrigerant

charge check

Is it okay?

Yes

Go to Step 10.

No

Go to next step.

8

Inspect refrigerant line In-

spect refrigerant lines.

Is piping free of damage

and cracks?

Are piping connections

free of oil grime?

(Visual Inspection)

Are piping connections

free of gas leakage?

Are piping installation

points on condense free

of gas leakage?

Are piping installation

points on receiver/drier

free of gas leakage?

Are piping installation

pints on A/C Compressor

free of gas leakage?

Are piping installation

points on cooling unit free

of gas leakage.

Perform gas leak inspec-

tion using gas leak tester.

Are above items okay?

Yes

Go to next step.

No

If piping or A/C component (s) is damaged or

cracked, replace then go to Step

19.Ifthere is gas

leakage, repair or replace connection and replace

condenser, then go Step 19.

9

Inspect evaporator piping

connections in cooling unit

for gas leakage

Are piping connections for

evaporator in cooling unit

free of gas leakage?

Yes

Adjust refrigerant amount to specified level, then

go to Step 19.

No

If piping damaged or cracked, replace then go to

Step 19.

If there is gas leakage, repair or replace connec-

tion and replace condenser then go to Step 19.

10

Verify whether malfunction is

in compressor oil or else-

where

Add 30 ml of compressor oil.

Is noise heard when racing

engine?

Yes

Go to next step.

No

Troubleshooting completed.

Explain repair to customer.