HVAC

29

1. AIR FROM VENTS NOT COLD ENOUGH

TROUBLESHOOTING HINTS

Drive belt malfunction: Step 1

Malfunction in blower unit or condenser:

Step 4, 5

Malfunction in receiver / drier, expansion valve ( valve close too much) or expansion valve heat-sensing tube

installed incorrectly: Step 8, 9

Malfunction in refrigerant lines: Step 10- 13

A/C compressor system malfunction, insufficient compressor oil:

Step 16

Too much compressor oil, expansion valve heat-sensing tube installed incorrectly, or malfunction in expan-

sion valve or heater unit’s air mix link system: Step 18- 19

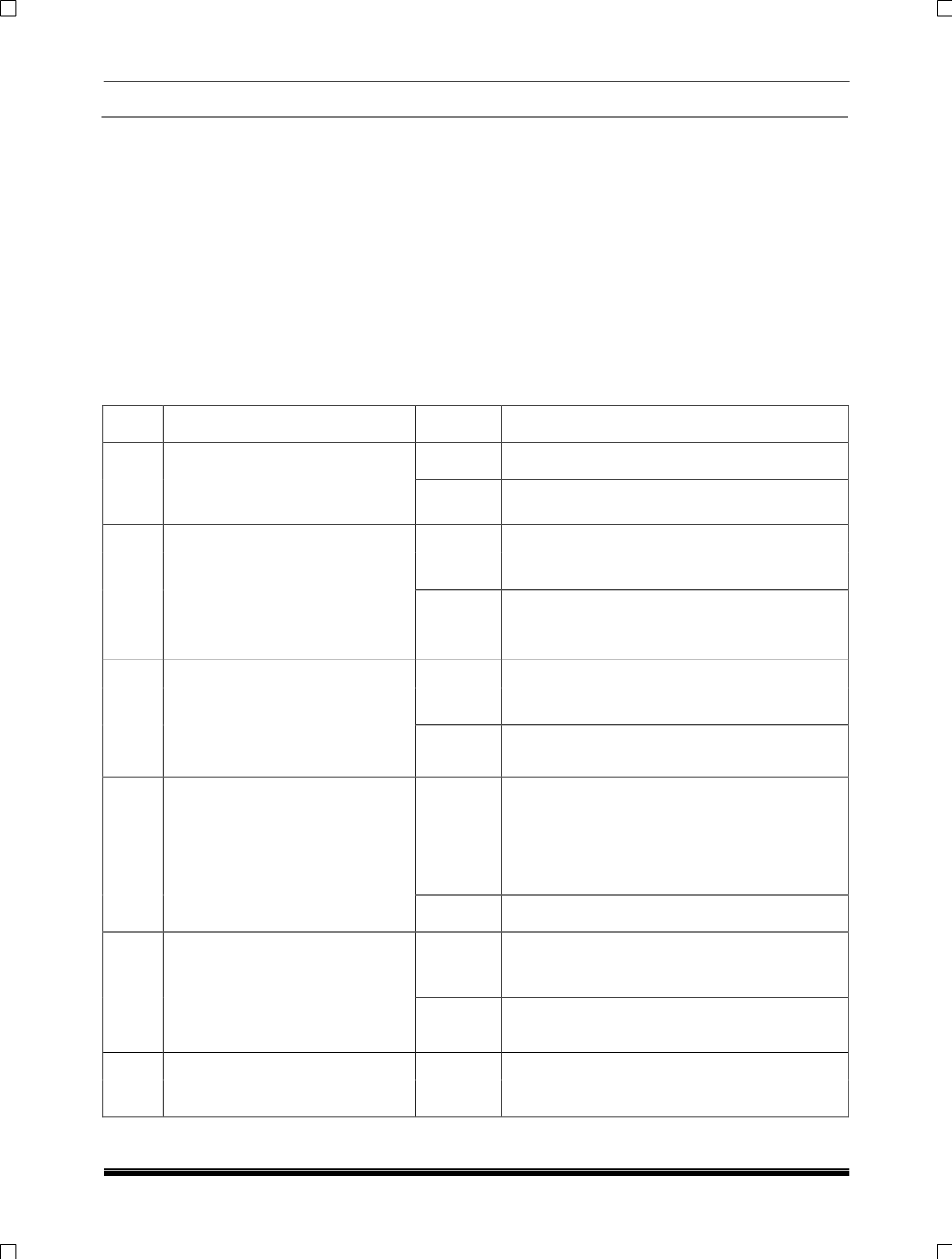

TROUBLE SHOOTING

STEP INSPECTION

ACTION

1

Inspect drive belt

See whether the belt is present or

fitted with correct tension.

Yes

Go to next step

No

Adjust or replace drive belt.

2

Inspect refrigerant system perfor-

mance

Perform refrigerant system perfor-

mance test (Refer AC system

performance test) is operating

normal?

Yes

Operation is normal. (Recheck malfunction symp-

toms)

No

Go to next step

3

Verify whether malfunction is in

blower unit intake and condenser

or another

Are refrigerant’s high-pressure and

low pressure values both high?

Yes

Go to next step.

No

Go to step 6.

4

Inspect blower unit intake is blower

unit intake clogged

Yes

Remove obstruction.

(If air does not reach evaporator within cooling

unit, heat exchange does not occur, refrigerant

pressure becomes high, and therefore, removal of

obstruction is necessary.)

No

Go to next step

5

Inspect condenser is it okay?

Yes

Adjust refrigerant to specified amount.

(Excessive amount of refrigerant.)

No

Replace condenser, or repair and clean conden-

ser fins.

6

Verify whether malfunction is in

expansion valve,

receiver/drier and refrigerant lines

Yes

Go to next step