HVAC

21

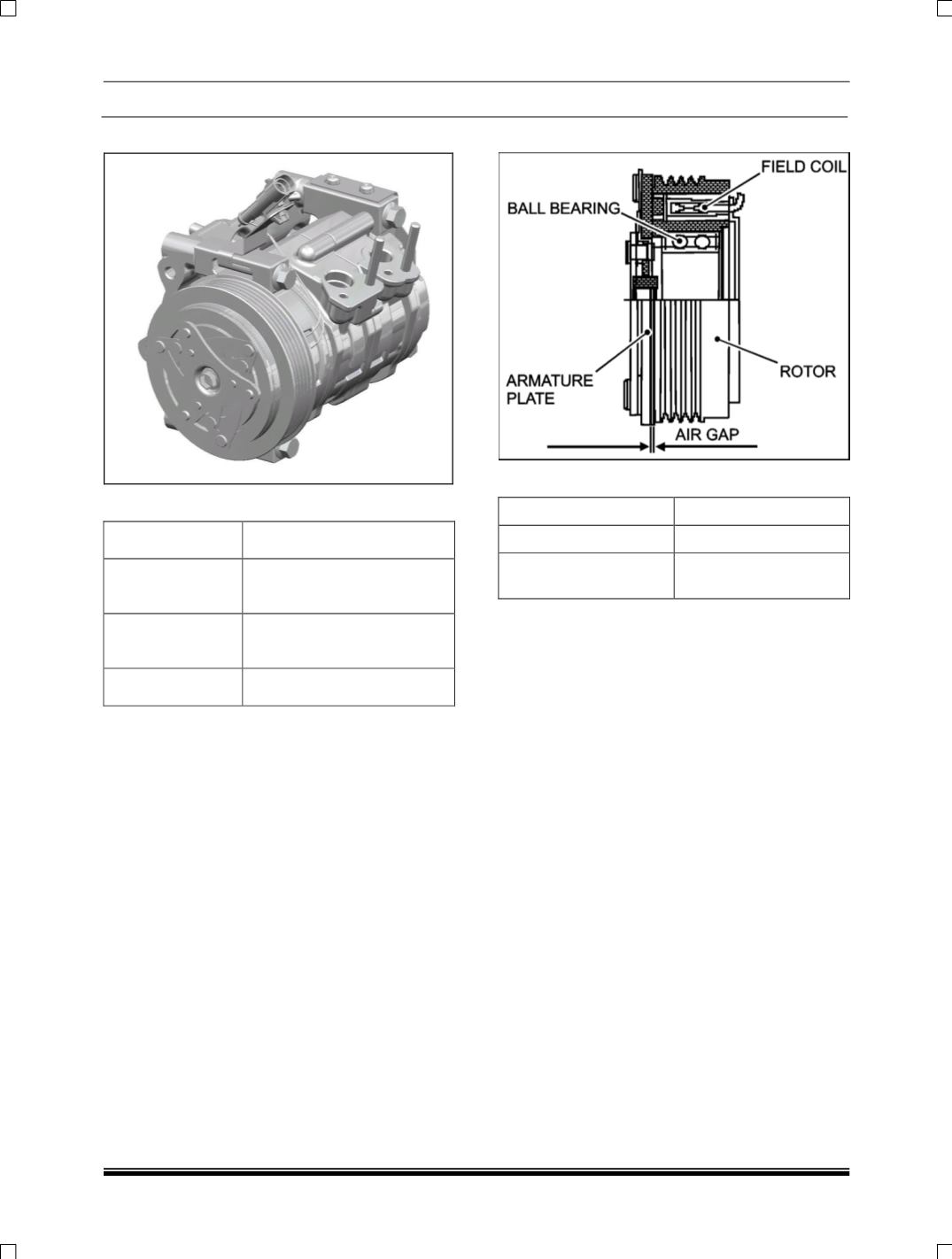

10.1.5.3. COMPRESSOR

SPECIFICATION

MODEL

10511

DISPLACEMENT

VOL.

116.7 cm

3

/ rev.

LUBRICANT

FD 46XG (PAG) or Equiva-

lent ND 8

QUANTITY

100 ± 15 cm

3

The Compressor used is piston type compressor.

This compressor has two identical scrolls arranged

at 180º around a offset center; one of them is fixed

(fixed scroll) and the other (orbit scroll) is turned at a

constant attitude, so that the space made between

the scrolls symmetrically around the rotating shaft

moves from outside toward the center while reducing

its volume; this is the principle of compression.

The moving scroll rolls and slides in small circular

movement with a small friction loss, ensuring smooth

operation even during start-up.

COMPRESSOR RELAY

Compressor relay is located in the MDU (

Main distri-

bution Unit)

located in the engine compartment

which is used to operate the compressor magnetic

clutch. The magnetic clutch continues to operate as

long as air conditioner is under operation. Once the

air conditioner is put in OFF condition, the compres-

sor relay gets cut off and the magnetic clutch gets

disengaged from the compressor. The cut - in and

cut - off of relay is governed by the ENGINE ECU.

MAGNETIC CLUTCH

SPECIFICATION

NOMINAL VOLTAGE

DC12V

AIR GAP

0.25 to 0.50mm

DIRECTION OF RO-

TATION

Clockwise

A magnetic clutch is used to connect and disconnect

the compressor from the engine.

Main components are stator, rotor, and pressure

plate.

PRINCIPLE

When the current is fed to the coil magnetic force is

generated in iron, which attracts any other iron.

CONSTRUCTION

A magnetic clutch consists of a stator, rotor with pul-

ley, and pressure plate to engage the drive pulley

and compressor magnetically. The stator is fixed on

the compressor housing, and the pressure plate is

attached to the compressor shaft. Two ball bearings

are used between the inner surface of the rotor and

the front housing of the compressor.

OPERATION

Whenever the engine is operating, the pulley is rotat-

ing since it is connected to the crankshaft by a belt,

but the compressor does not operate until the clutch

is energized. When the air conditioning system is

switched ON, the ECU generates a signal for ener-

gizing the compressor. The electromagnet attracts

the pressure plate and pulls the plate against the

friction facings on the pulley. The friction between

the facing and plate causes the clutch assembly to

rotate as a unit, and drive the compressor.