BRAKES

11

6.7 VACUUM BRAKE BOOSTER

General:

TATA BOLT is equipped with a mechanical

vacuum booster to assist driver’s pedal effort.

This is achieved by using vacuum from engine

inlet manifold (for petrol engines) or vacuum

pump (for diesel engines). A diaphragm is

provided between the two shells of the booster,

the difference of pressure on two sides of

diaphragm (one side vacuum and another side

atmospheric

pressure)

gives

mechanical

advantage. This amplifies the driver’s pedal effort

while braking.

The unit is connected to the brake pedal and the

master cylinder. The vacuum booster input push

rod is connected to brake pedal while the output

push rod operates the master cylinder. If failure of

vacuum occurs, the two push rods act as a single

rod and the brakes will work in the conventional

manner, but more pedal effort will be required and

the fatigue of the driver will increase.

NOTE:

The booster assembly and TMC assembly are

coupled with the help of fasteners. The mating

dimensions of booster and TMC are factory

set hence:

1. Do not alter the height of the output rod of

the vacuum booster unit at any stage and

ensure booster output rod is correctly

aligned to the primary piston bore during

assembly of TMC to the booster.

2. Once the booster assembly is removed

from vehicle, at the time of refitting on

vehicle, the gasket at the mounting face of

the booster should be replaced with a new

one.

3. Booster assembly is a non-serviceable unit

and it should never be tampered with.

Working Principle of Vacuum Booster:

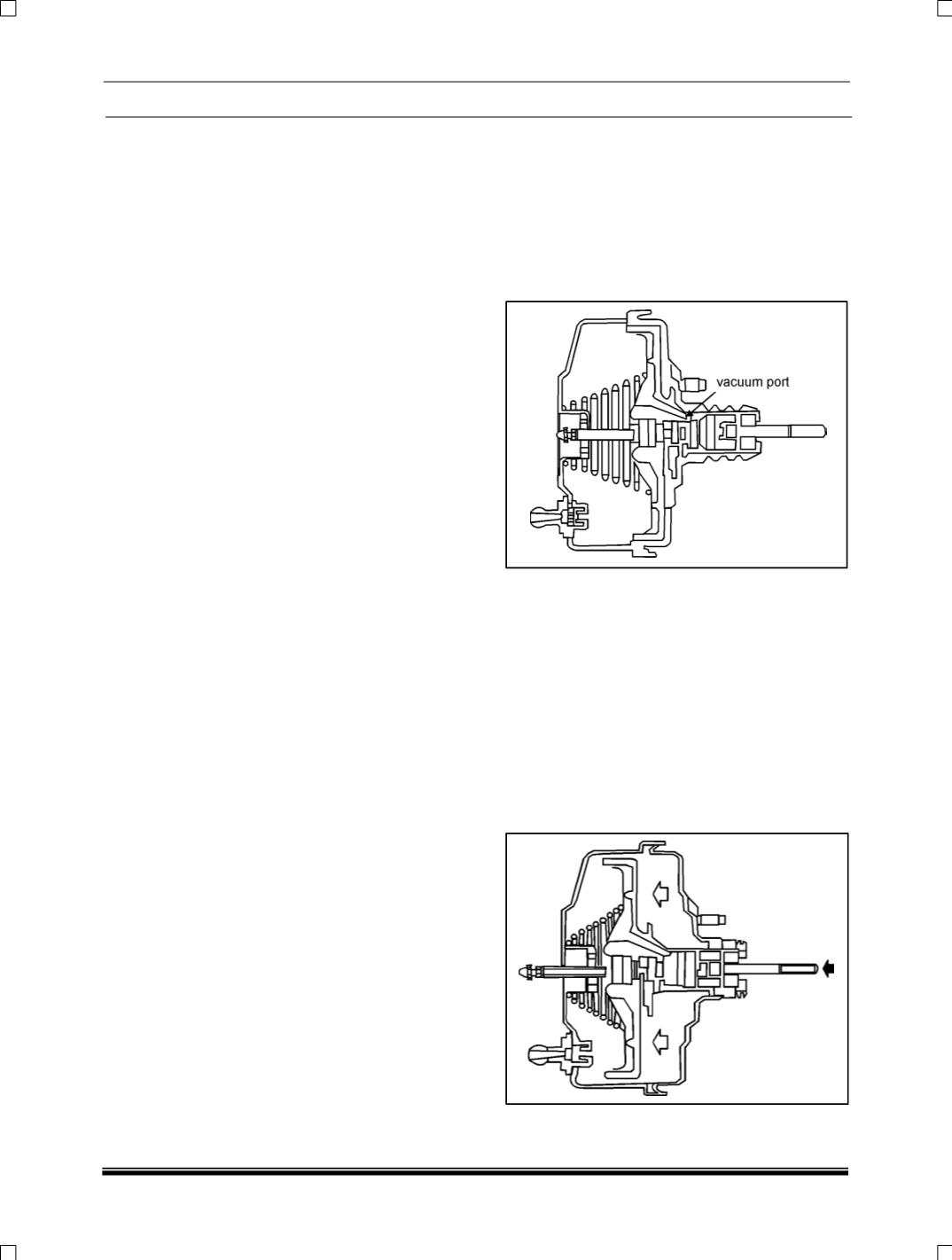

1. Brakes OFF

The diaphragm is fully retracted and is held

against the rear shell by the diaphragm return

spring. The in- put rod assembly is also fully

retracted by the brake pedal return spring. With

the input rod in this position, the vacuum port is

open and the vacuum is applied on both the sides

of the diaphragm

2. Brakes Applied

When the brake pedal is depressed, the input rod

assembly moves forward inside the diaphragm

plate until the control valve closes the vacuum

port; at this stage vacuum is still present on both

the sides of the diaphragm. As the input rod

continues to move for- ward, the control plunger

moves away from the control valve, opening the

atmospheric port, which is formed between these

two parts. Air enters the rear shell behind the

diaphragm and the effect of atmospheric pressure

assisted by the valve rod helps in pushing the

diaphragm plate forward and thus the out- put rod

actuates the TMC plunger.