DRIVETRAIN-TA65 Star

28

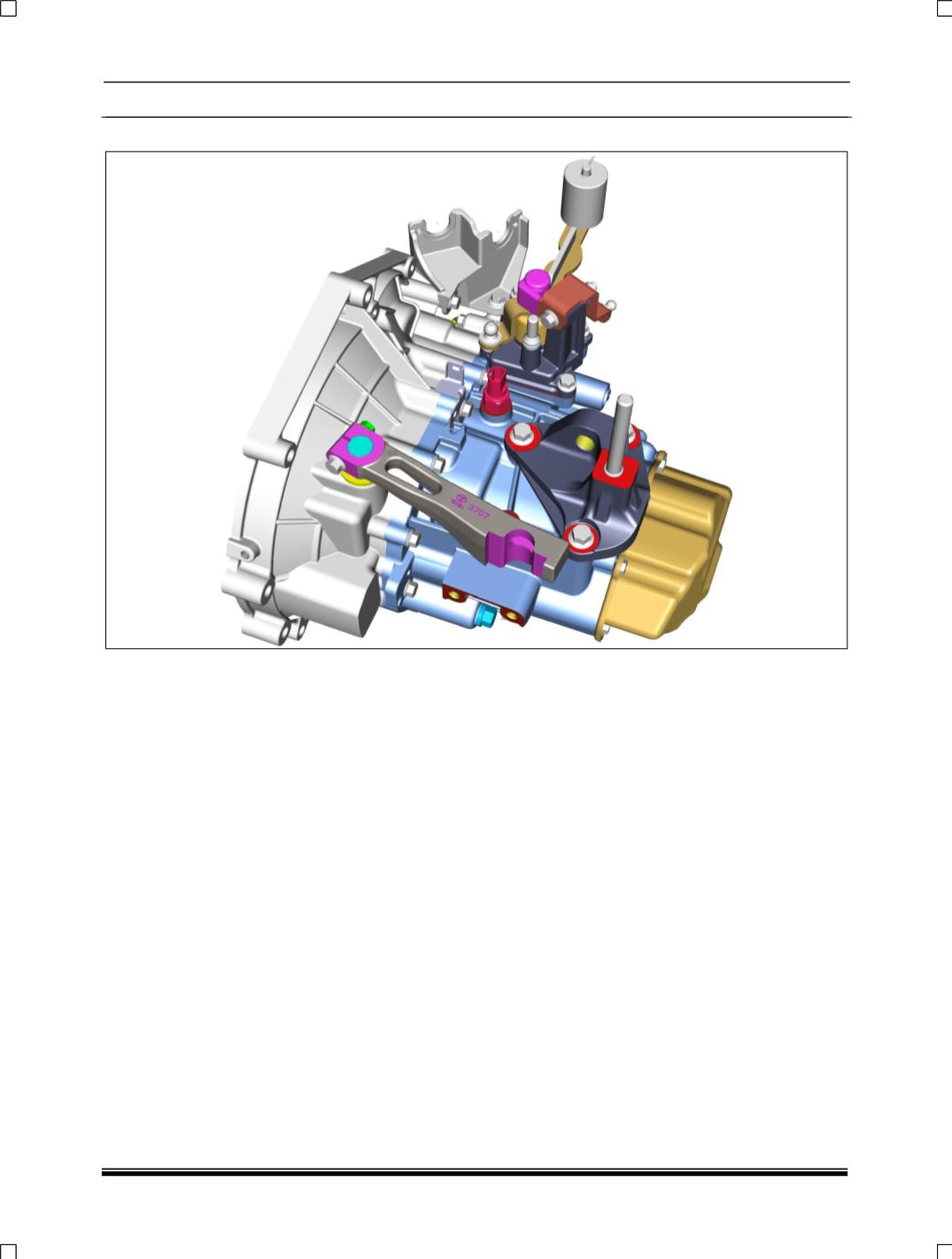

4.7. TRANSAXLE

4.7. A. GENERAL DESCRIPTION

TA65 star is similar transmission as current TA65

as regards the architecture of input shaft, lay shaft

and differential final drive, bearings and oil seals.

The transmission TA65* provides five forward

speeds and one reverse speed by means of three

synchronizers and input shaft, lay shaft and

reverse idler shaft and differential. All forward

gears are in constant mesh engaged through

synchronizers and reverse gear uses a sliding idler

gear arrangement.

All the synchronizers are mounted on lay shaft and

engaged with gears on lay shaft. The lay shaft

turns the final drive gear and differential assembly,

thereby turning the front drive shafts which are

attached to the front wheels.

Movement of gear shift lever / knob is transmitted

through gear shift cables and shift /select levers on

transmission to the selector shifting finger. This is

further transmitted through shifter dogs and shifter

forks to the shifter sleeves and synchronizers.

Interlock piece is provided to prevent double

engagement of gears. Inhibitor is provided to block

direct shift from 5th gear to Reverse gear which

guides the shift lever towards 4th gear. Central

detent is provided for distinct position of gears

about neutral position.

CHANGES AND BENEFITS OVER TA65:

The major areas of change and benefits over TA65

are:

1. The internal and external gear shifting

mechanism and arrangement. TA65 star

employees cable shift in place of current rod

shift for TA65.

The advantages of cable shift over rod shift are:

Better end stop feel.

No gear shift lever vibrations. No gear lever

rocking

Ease of routing / packaging, better

serviceability.

2. Twin cone carbon lined synchronizers for first

and second gears to replace single cone brass

synchronizers. Benefits are improved shift

smoothness, reduction in shift efforts and

enhanced life of synchro cones.

3. Deletion of intermediate plate and its integration

into housing front half. This has improved the

housing rigidity and accuracy of gear train

positioning thus helping reduction in noise level.