AIR CONDITIONING

26

11.9 MAIN PARTS OF A.C. SYSTEM

1. COMPRESSOR

: It is the heart of A.C. system

where, low temperature, low pressure vapour

refrigerant is compressed and converted to

high temperature high pressure gas.

2. CONDENSER:

It is the place where heat

dissipation takes place. Hot compressed gas

enters the condenser and is cooled off and

converted into high pressure liquid at the

condenser outlet.

3. RECEIVER DRIER INTEGRATED WITH

CONDENSER

: It serves as a reservoir for

excess refrigerant where it removes any

traces of moisture and filters out dirt in the

system.

4. LINEAR PRESSURE SWITCH:

It is used to

limit pressure conditions in a closed

refrigerant cycle for series / parallel logic.

High Low Pressure Settings: If the system

Pressure reaches impermissible levels i. e. if

the pressure is less than 2 ± 0.2 kg/cm2 or if

the pressure is higher than 32 ± 2 kg/cm2

then the compressor is switched off. This

avoids its consequential damage.

Medium Pressure Settings: Due to these

pressure settings, both the condenser fan and

radiator fan start immediately after the A. C. is

switched ON. Both the fans run at slow speed

until the system pressure exceeds 20.5 kg /

cm2 Above this pressure, both the fans run at

full speed. When the system pressure drops

below 15.5 kg / cm2, both the fans will run at

slow speed.

5. EXPANSION VALVE:

It senses the pressure

of the refrigerant coming into the evaporator

as well as the temperature of the refrigerant

into the evaporator. By sensing the

temperature and the pressure of the gas

leaving the evaporator, the expansion valve

prevents the evaporator from being flooded,

and thereby returning liquid refrigerant to the

compressor.

6. EVAPORATOR:

It serves as a heat

absorption unit. Here it removes heat from

inside the vehicle and dehumidifies it. The

refrigerant enters the bottom of evaporator as

a low pressure liquid. The warm air passing

through evaporator fins causes the refrigerant

to boil; it can absorb large amounts of heat.

The heat is then carried off with the refrigerant

to the outside of vehicle.

7. ANTI FREEZE SWITCH:

It is a temperature

sensing device, which protects the A.C.

systems from damage. It switches off the

compressor when condensed water tends to

form ice on the fins of evaporator. Thus it

maintains the evaporator temperature within a

specified range.

8.

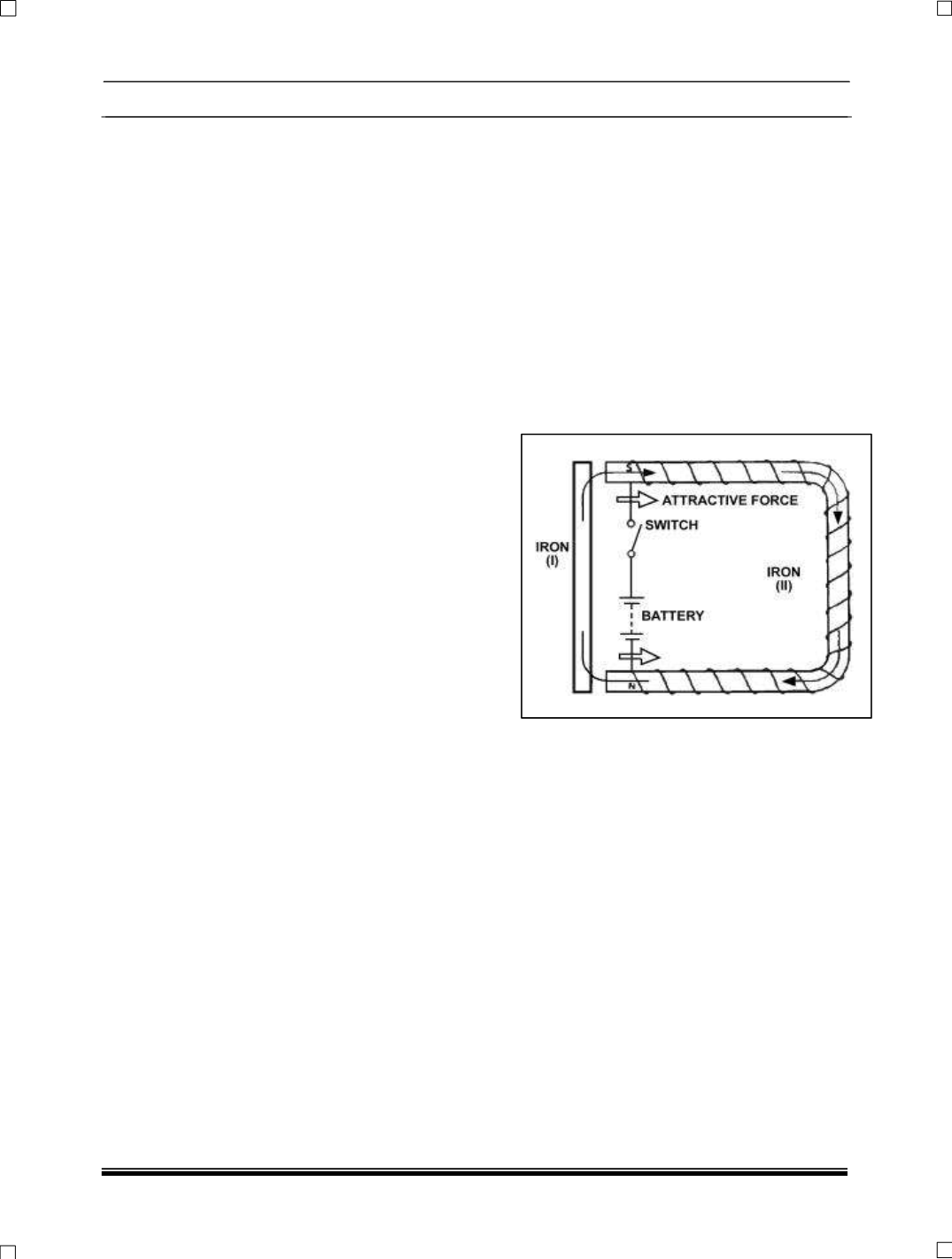

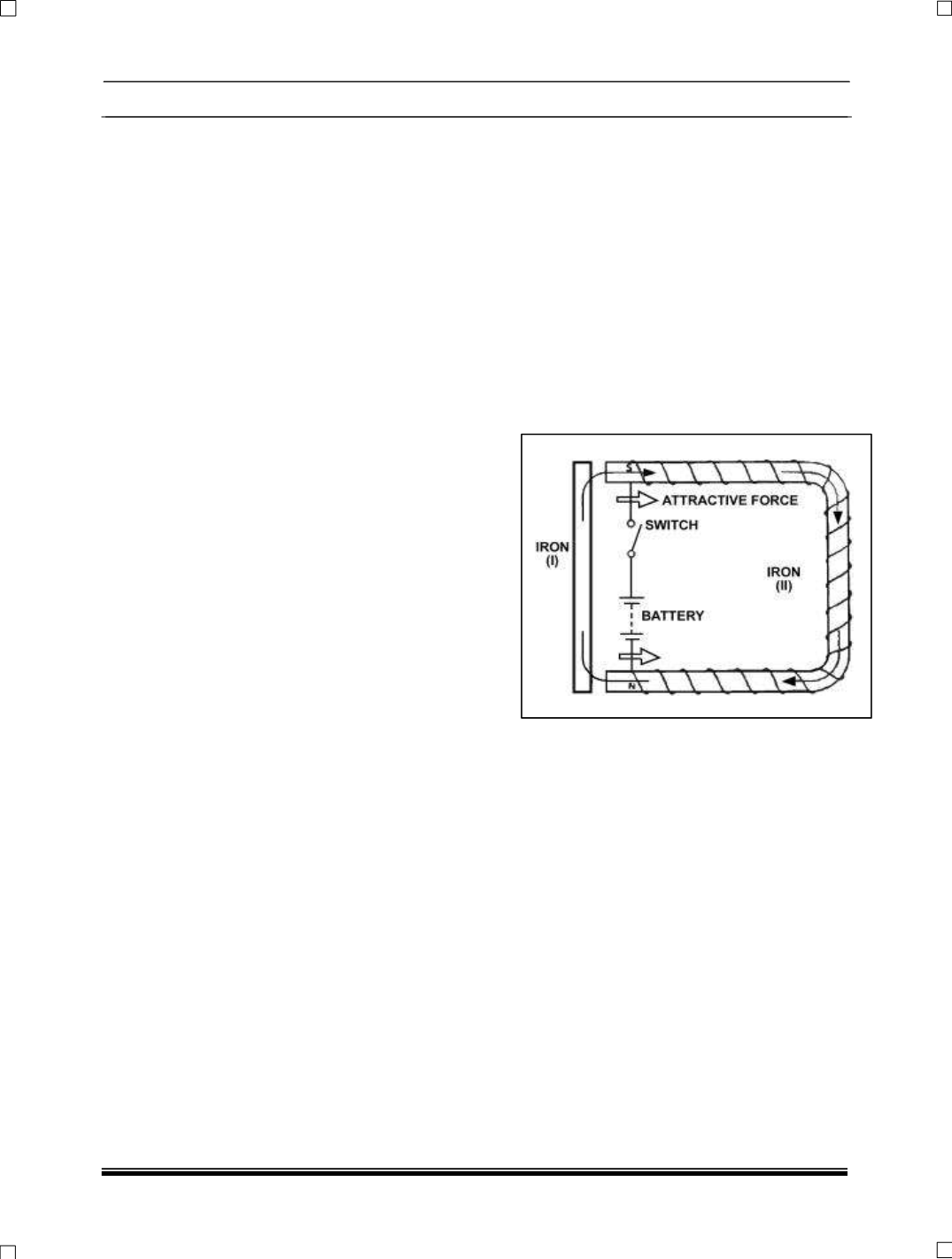

MAGNETIC CLUTCH

:

A magnetic clutch is used to connect and

disconnect the compressor from the engine. Main

components are stator, rotor, and pressure plate.

PRINCIPLE:

When the current is fed to the coil (as shown fig. B

on the right), magnetic force is generated in iron II

which attracts iron I.