DRIVETRAIN C549

40

NOTE

: 0.12

corresponds to the recommended

interference for the bedding in and pre-loading

of the differential bearings.

4. After determining the exact value of the size

of the shim, try to get as close as possible to

this value using the shims supplied as spares.

If there are no shims available that

correspond exactly to the value produced in

this way, fit the shim(s) immediately larger.

5. Place the differential bearing pre-loading shim

(s) in position.

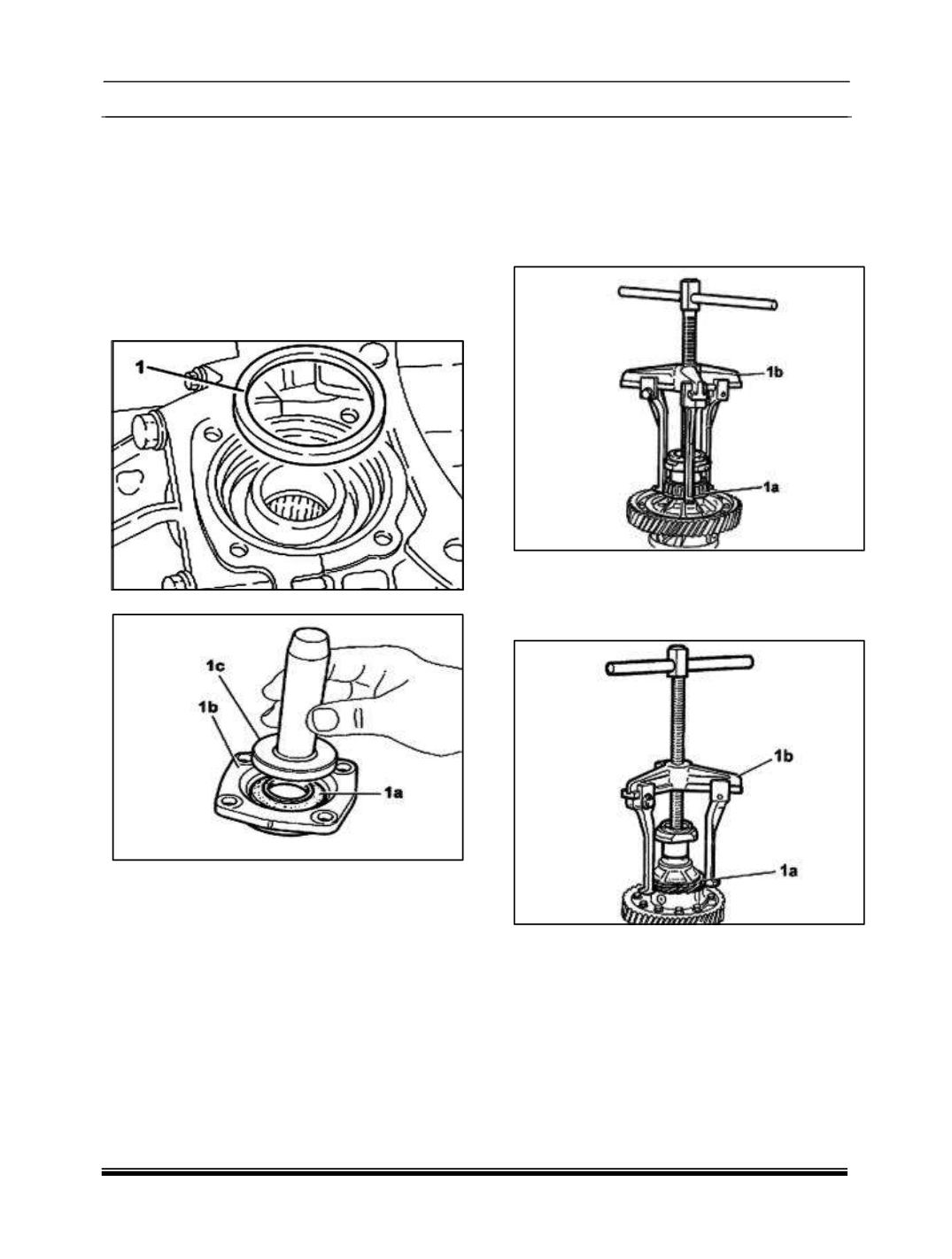

6. Fit a new oil seal (1a) on the differential flange

7. (1b) using the

tool (1c)

287458902611

(Fitting tool) .

Fit the differential flange and

secure it tightening the bolts to torque.

8. Fit the left differential inner driveshaft.

9. Fit the gear selection/engagement mounting

bracket and secure it using the bolts.

10. Unscrew the fastenings and remove the

TRANSAXLE and differential from the support

tool

287058900607

(TRANSAXLE Support).

11. Remove the support tool from the overhaul

stand and put it down.

12. Refit the TRANSAXLE assembly on vehicle

using suitable transaxle support bracket.

4.1.2.5. DIFFERENTIAL ASSEMBLY –

OVERHAUL

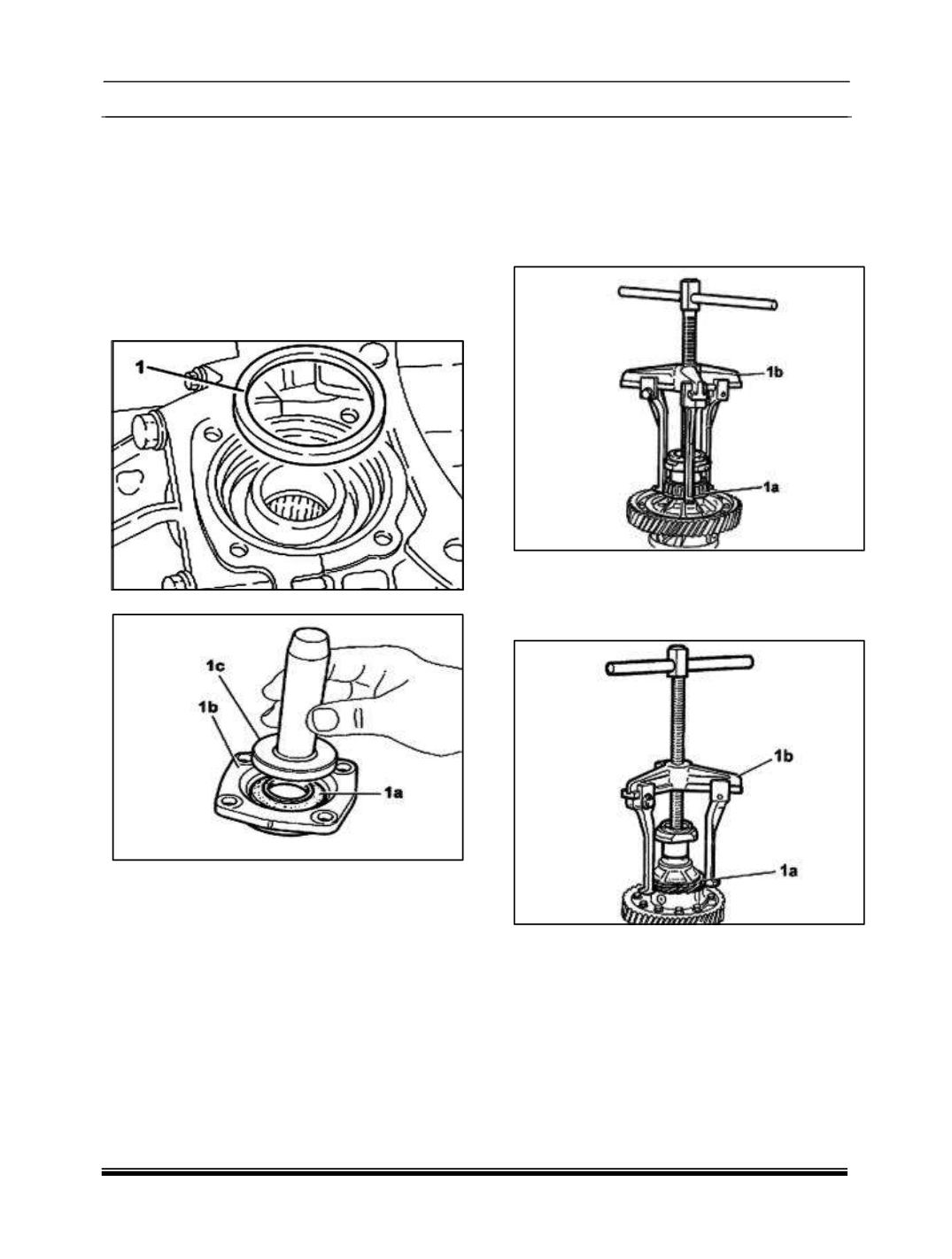

1. Remove the bearings (1a) from the differential

internal casing using the tools (1b)

287458902619 (Extractor), (1c) 28745890

2620

(Extractor

arms)

and

(1d)

287458902621 (Fitting Tool).

2. Remove the speedometer idler drive gear (1a)

using the tools (1b) 287458902619

(extractor), (1c) 287458902620 (Extractor)

and (1d) 287458902621 (Fitting tool).

3. Mark the position of the ring gear and

differential internal casing.