DRIVETRAIN C549

39

14.Position the fork (2) so that the tapered part is

in the same direction as that of the sleeve,

resting it against the side of the sleeve with the

smaller diameter.

15.Fit the fork manually, exerting the necessary

pressure, until it is completely inserted in the

sleeve.

NOTE: When the fitting is complete, check that

the sleeve can rotate freely inside the fork.

16.Apply sealant to the contact surfaces between

the main and lay shaft rear bearings retaining

plate and the rear cover.

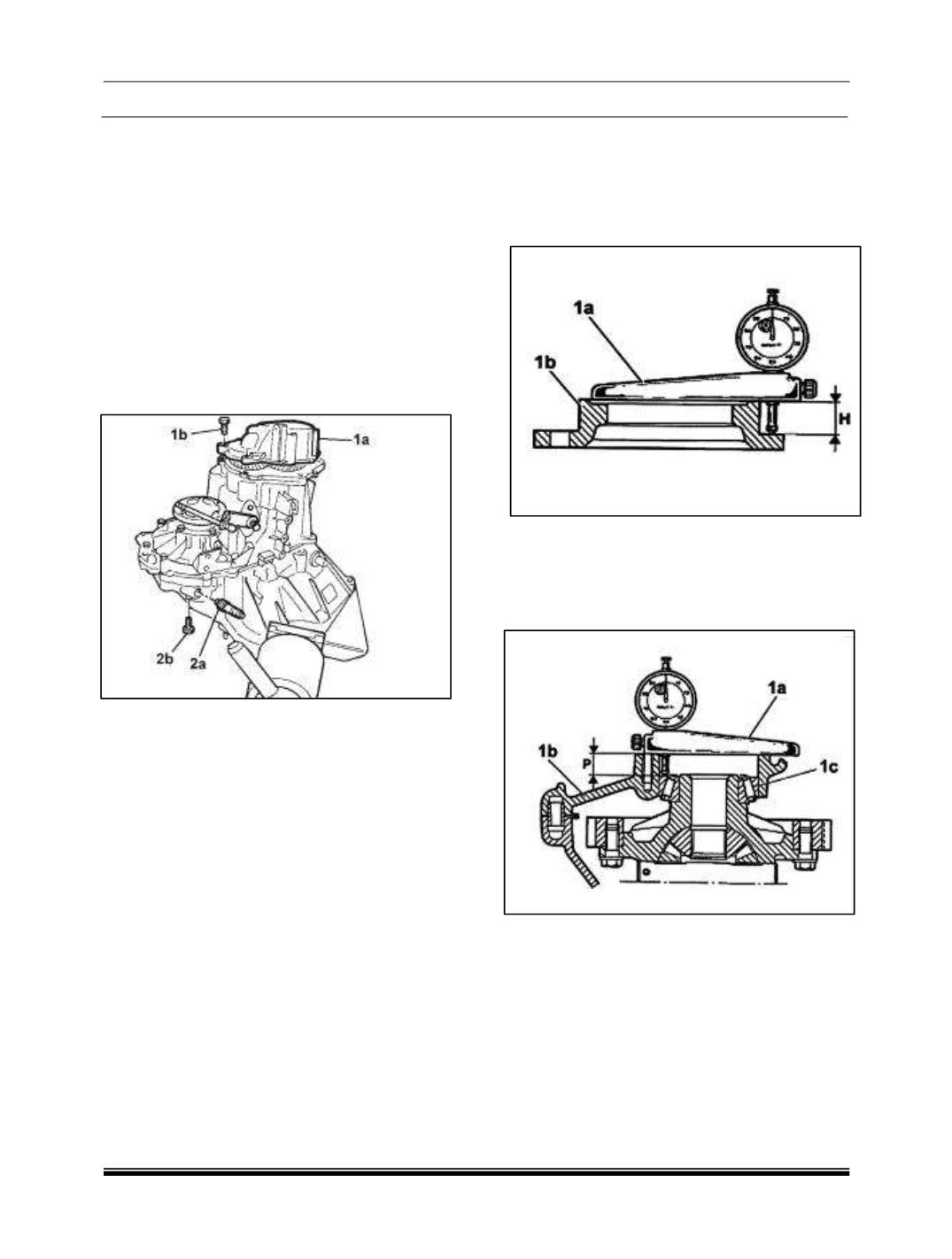

17.Fit the rear cover (1a) and secure it tightening

the M8 bolts (1b) to a torque of 2.1 ~ 2.6 da

Nm.

18.Fit the odometer idler gear (2a) and secure it

with screw (2b).

J. DETERMTION OF DIFFERENTIAL

BEARING PRE-LOADING SHIM

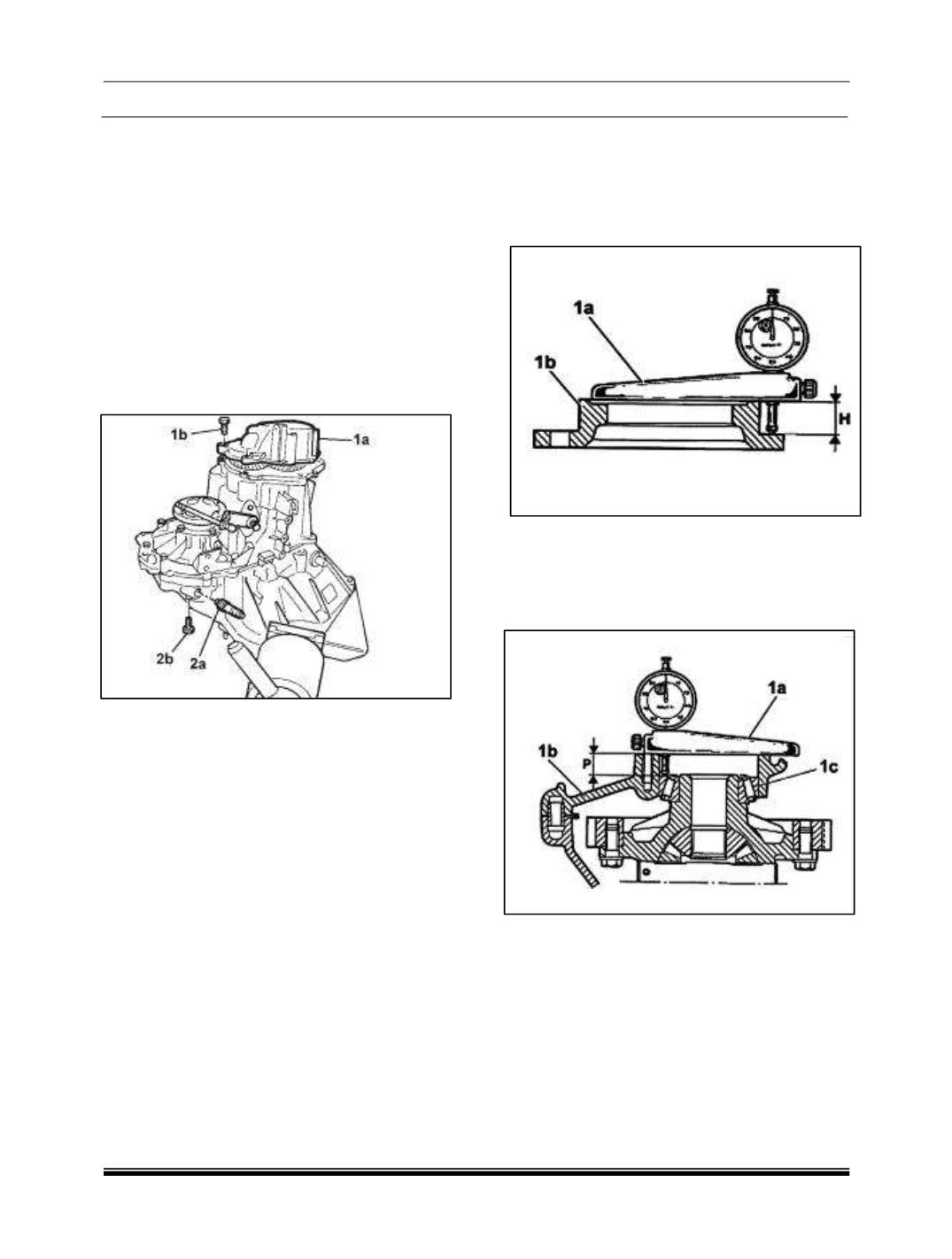

1. Position the

tool (1a) 287458902612 (Mount),

complete with dial gauge, on the differential

flange (1b) and measure distance “H” (flange

height).

2. Position the

tool (1a) 287458902612 (Mount

)

complete with dial gauge on the differential

flange support surface (1b) and measure

distance “P”(depth between differential flange

support plane and bearing outer race (1c).

3. Calculate the thickness “S” of the differential

bearing pre-loading shim using the following

formula:

S = (P – H) + 0.12

Where

S

= Differential bearing pre loading shim

thickness.

P

= Depth between differential flange support

plane and bearing outer race.

H

= Flange height.