DRIVETRAIN C549

4

4.1.1.3 MAINTENANCE

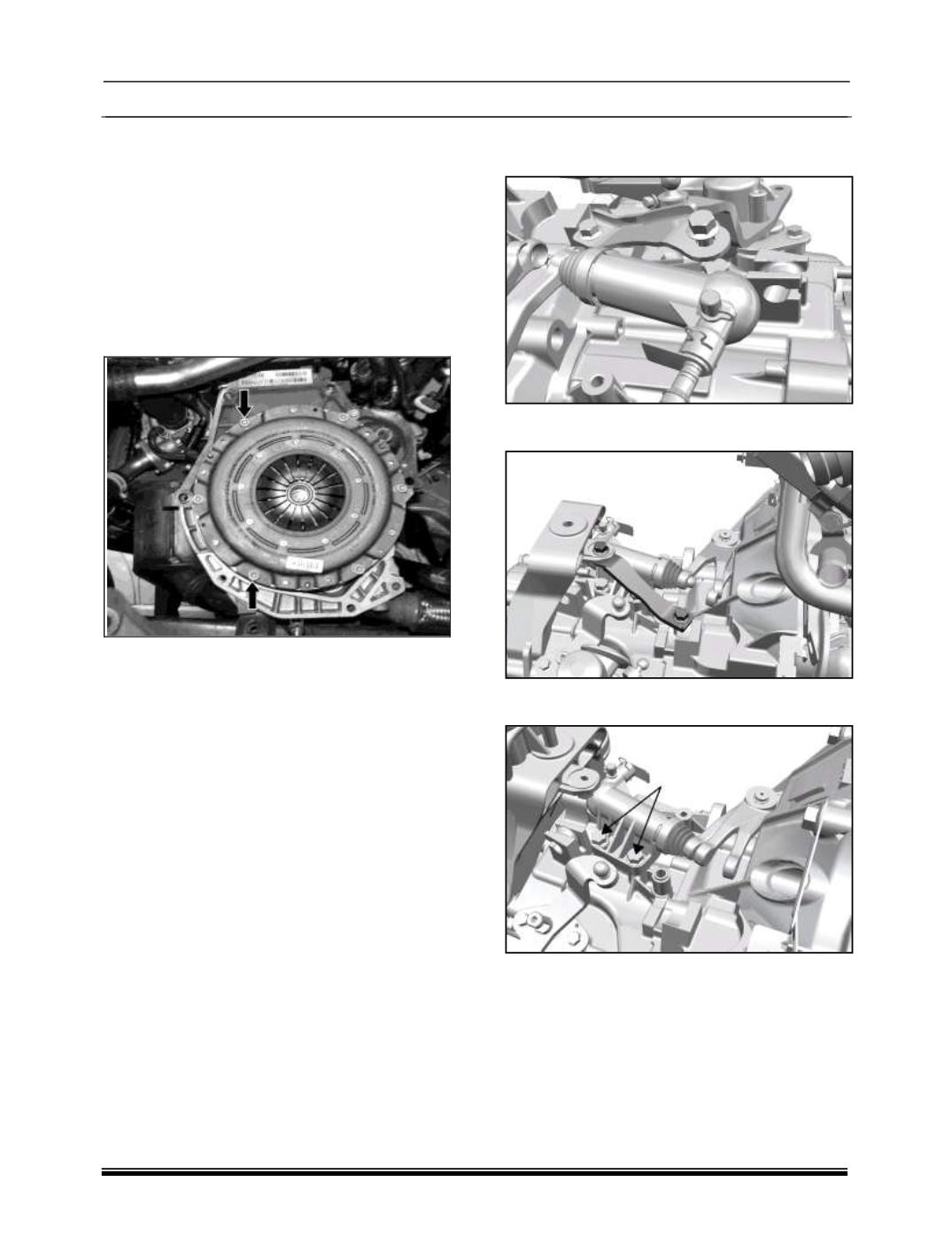

A. CLUTCH ASSEMBLY REMOVAL

1. Remove the Transaxle assembly from the

engine, for procedures refer, TRANSAXLE

REMOVAL.

2. Use suitable flywheel lock tool.

3. Removal the bolts diagonally and remove the

clutch mechanism complete with plate

NOTE:

The bolts are pre-treated with sealant and

therefore they should be replaced each time

they are refitted.

INSTALLATION:

1. Place the clutch mechanism in its housing

using a suitable clutch locating tool.

2. Tighten the new M8 bolts diagonally securing

the clutch mechanism to the recommended

torque of2.5 ~ 3.1 Kg-m.

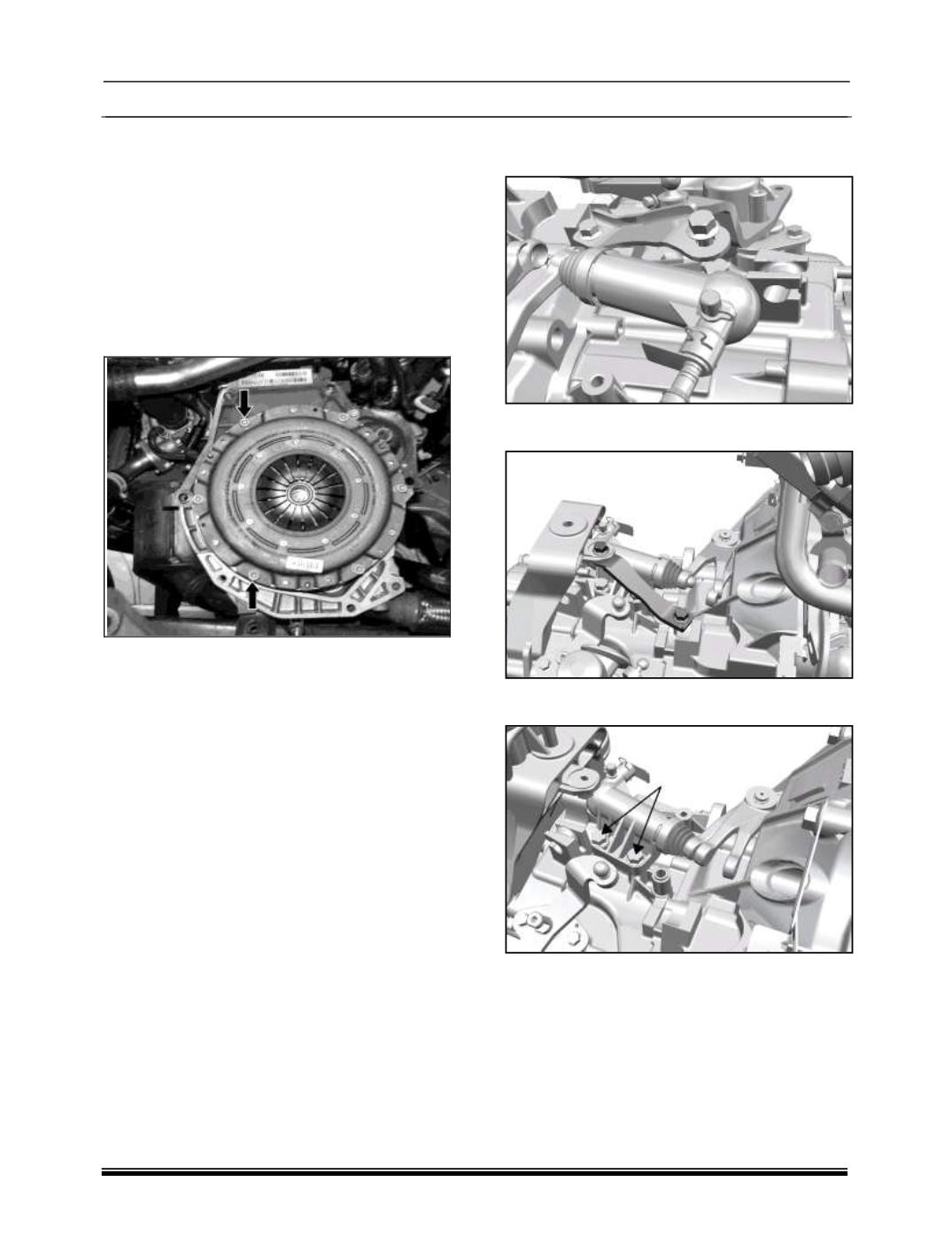

B. HYDRAULLIC ACTUATOR - REMOVAL

1. Mount the Vehicle on a two post lift.

2. Lift up the clip and disconnect the clutch fluid

pipe on the clutch slave cylinder.

3. Remove the fasteners of Brace (B mount) and

remove the Brace.

4. Loosen and remove the mounting fasteners of

the Clutch Slave cylinder.

INSTALLATION

1. Place the operating cylinder in position and

secure it tightening the mounting bolts to the

recommended torque of 1.8 ~ 2.2 Kg-m.

2. Refit the Brace (B Mount) and secure it by

tightening the mounting bolts.