ENGINE 1.3L QUADRAJET (90PS)

94

3.1.7 EXHAUST SYSTEM

A. DESCRIPTION

The Exhaust system of 1.3 Quadrajet consists of a

Catalytic converter, Lambda Probe and EGRwith heat

exchanger other than the other conventional

components like Exhaust Manifold, silencer, etc.,

B. COMPONENTS

CATALYTIC CONVERTER

The catalytic converter is a post-treatment device for

oxidizing the CO, HC and particles transforming them

into carbon dioxide (CO

2

) and water vapour (H

2

0).

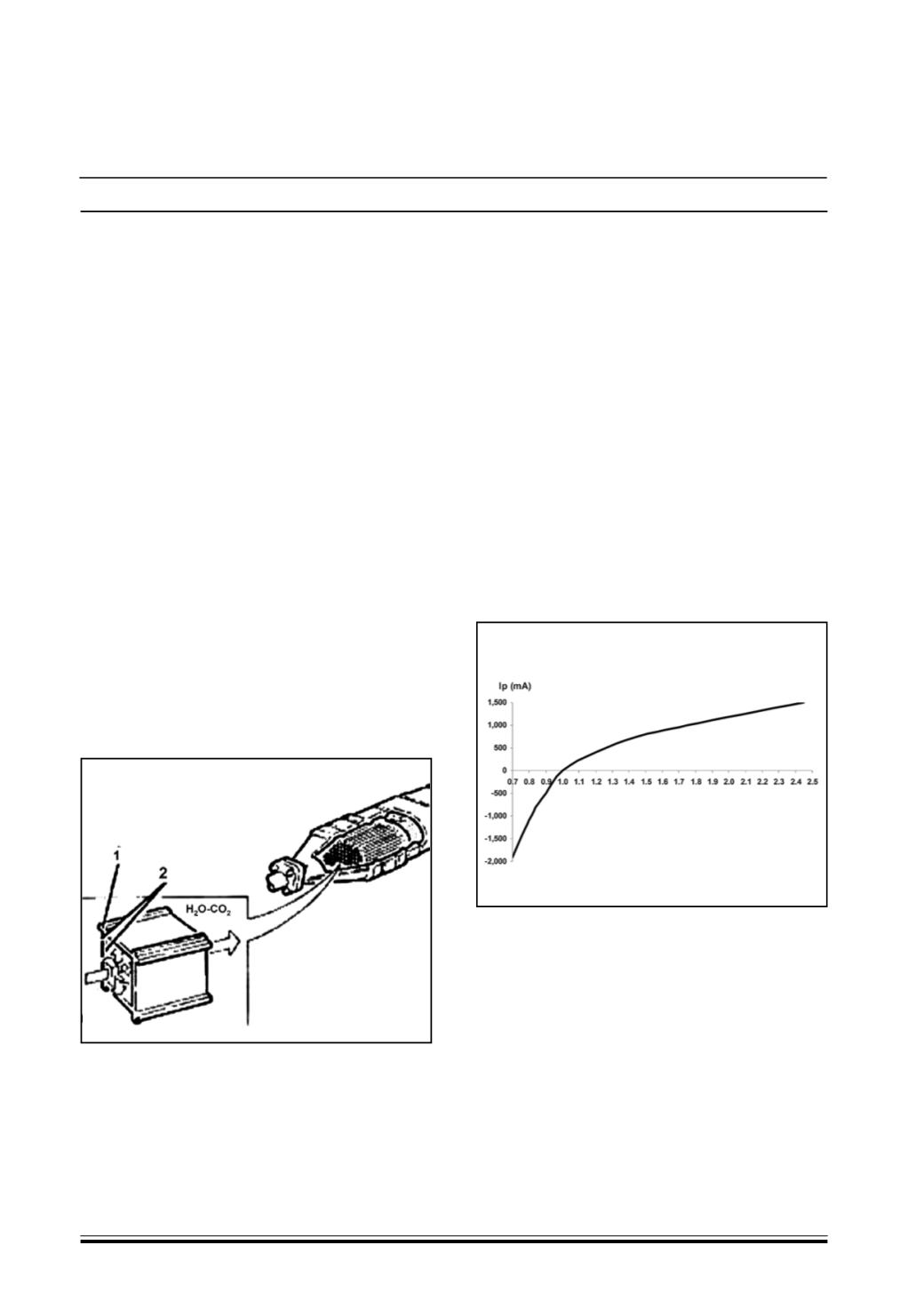

The catalytic converter consists of a ceramic,

honeycomb structure (1) with cells impregnated with

platinum (2) which catalyzes the oxidation reactions.

The exhaust gases passing through the cells heat

the catalyzer triggering off the conversion of the

pollutants into inert compounds.

The oxidizing chemical reaction of the CO, HC and

particles is effective at temperatures of between 200

and 350°C.

In effect, above 350°C the sulphur contained in the

diesel fuel starts to oxidize producing sulphur dioxide

and sulphur trioxide.

LAMBDAPROBE

The linear “UEGO” planar type Lambda sensor is fitted

on the catalytic converter and informs the engine

management control unit of the combustion progress

The sensor is an oxygen sensor containing two

comparative cells that make it possible to measure ë

values (ratio between the quantity of intake air and the

theoretical quantity of air required for the complete

combustion of the fuel injected) between a wide range

from ë = 0.7 (rich mixture) to the value in air (ë= (lean

mixture).

It is used to compare the reading of the air flow meter

with the one mapped in the control unit and, if

necessary, correct the fuel injection to be within the

emission limits.

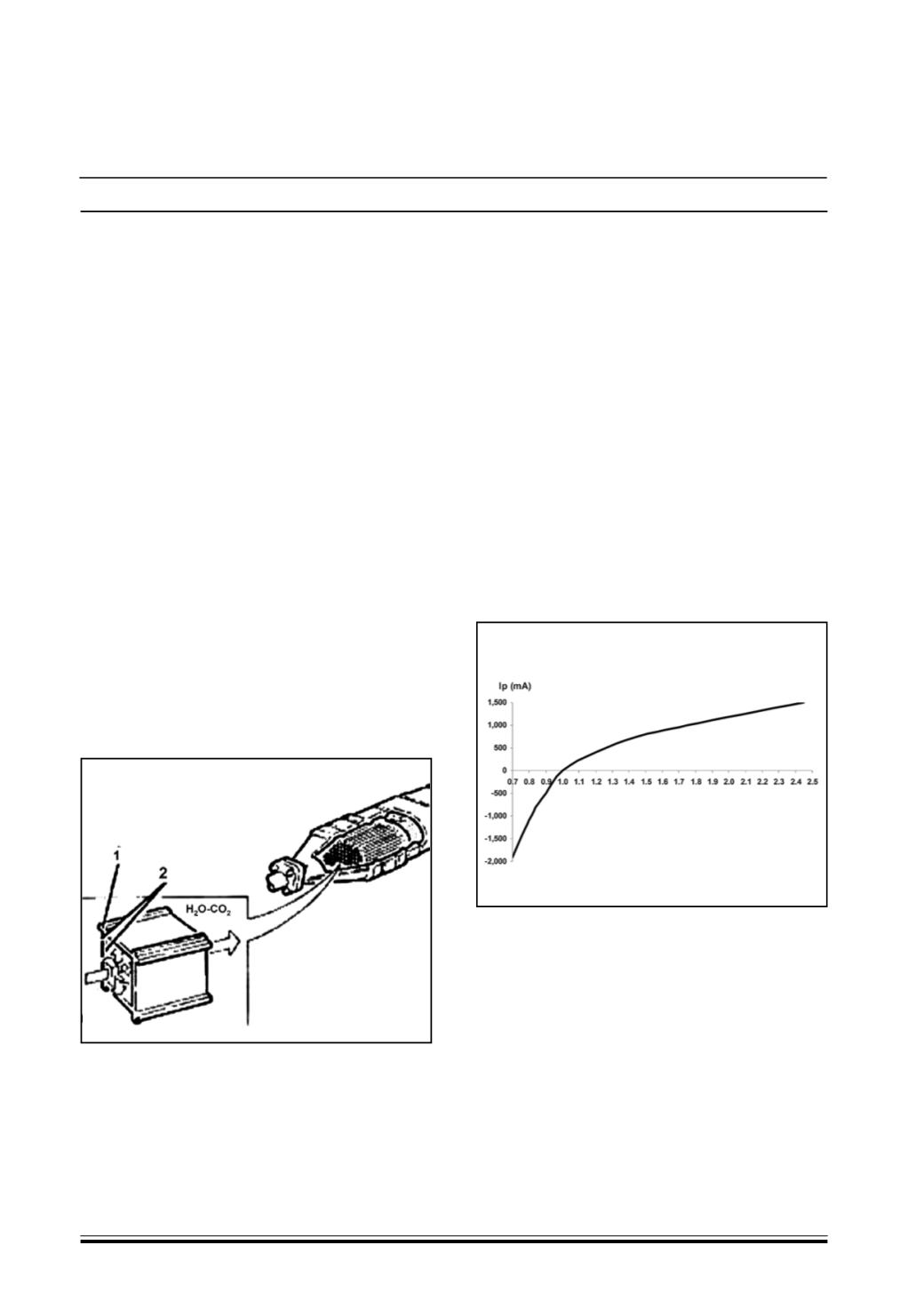

The sensor works by comparing the concentration of

oxygen in the reference cell, housed inside the sensor,

with the combustion gas flowing inside the

comparison cell next to the reference cell. Depending

on the resulting imbalance, the engine management

control unit regulates a current signal (lp) that

rebalances the oxygen content in the comparison cell

through an electrochemical action. The value of lp is

proportional to the ë value measured according to

the graph illustrated below.

In order to activate the operation of the sensor quickly,

the sensor contains a heater operated in duty cycle

by the engine management control unit according to

a calibrated strategy.

The two comparison cells and the heater are

incorporated in the same planar ceramic element

(layers of several ceramic elements) in order to keep

the structure compact and guarantee high response

and heating speeds for the actual element.

HC-CO-C