ENGINE 1.3L QUADRAJET (90PS)

92

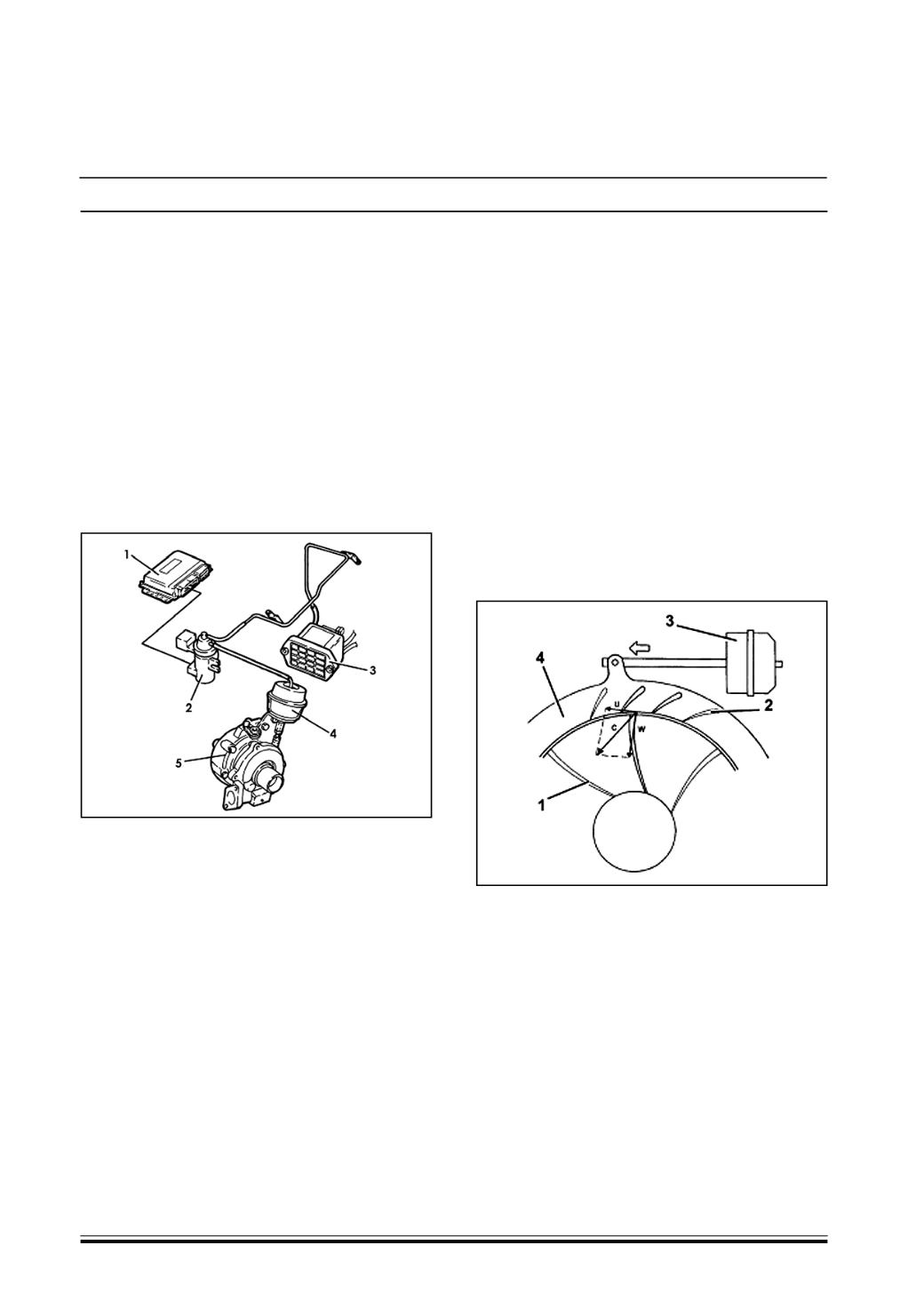

Operation at low rotation speeds:

When the engine runs at a low rotation speed, the

exhaust gases possess little kinetic energy; in these

conditions a traditional turbine would turn slowly,

providing limited supercharging pressure.

In the variable geometry turbine (1) on the other hand,

the moving vanes (2) are in the maximum closed

position and the small sections between the vanes

increase the speed (C) of the exhaust gases

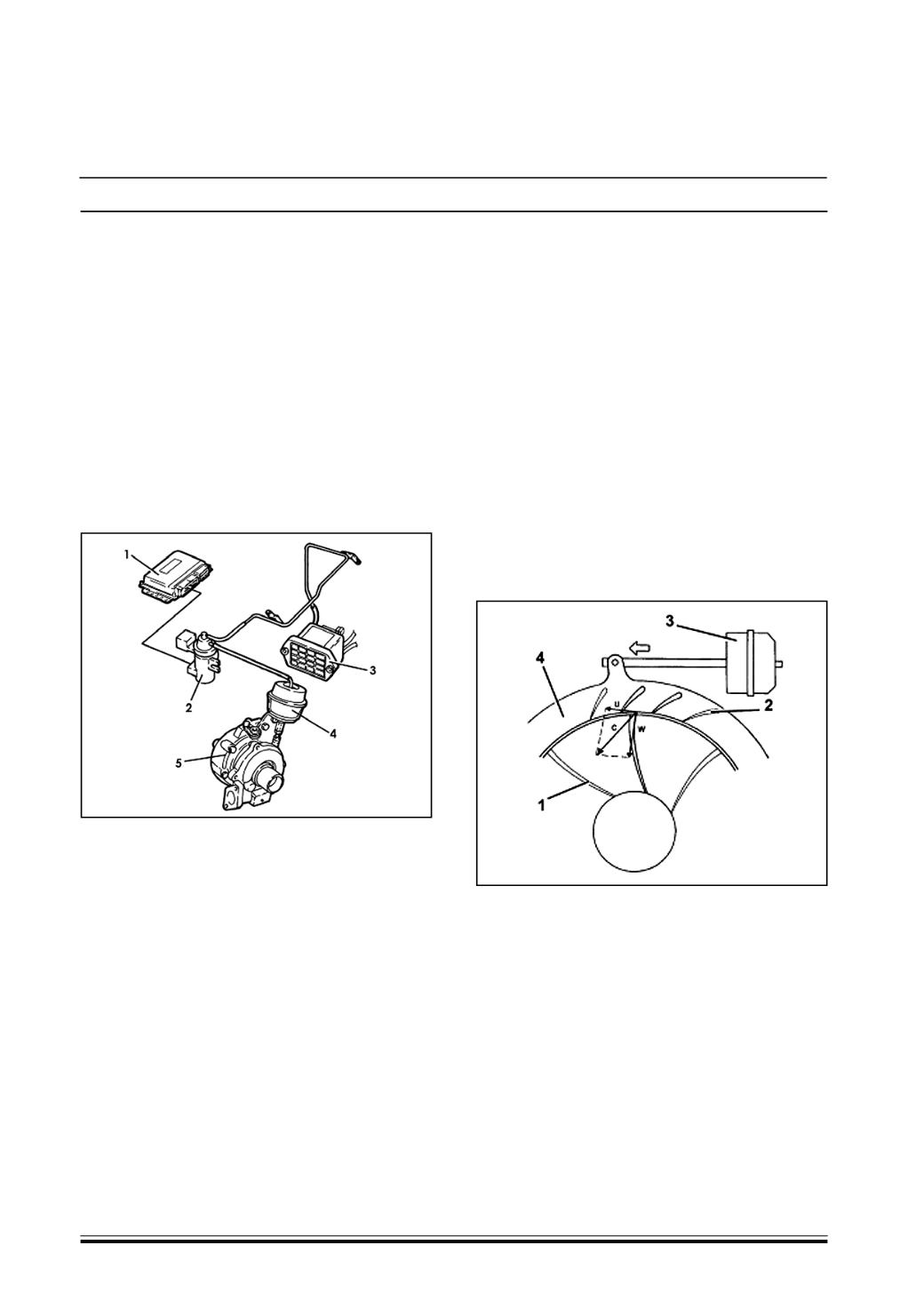

TURBOCHARGER – VGT TYPE

It is the variable geometry turbine (VGT) type and is

connected to the exhaust manifold. It is designed to

increase the volumetric efficiency of the engine.

Variable geometry type turbochargers are composed

of:

Q

a centrifugal compressor

Q

a turbine

Q

a series of moving vanes

Q

a pneumatic actuator controlling the moving vanes.

The management of the operation of the turbocharger

variable geometry is controlled by the control unit

through the operation of the VGT solenoid valve.

1. Engine management control unit

2. VGT solenoid valve

3. Vacuum reservoir

4. Moving vane control actuator

5. Turbocharger

The variable geometry turbocharger makes it

possible to:

(a) Increase the speed of the exhaust gases in the

turbine at low engine speeds

(b) Slow down the speed of the exhaust gases in the

turbine at high speeds.

Controlling the speed (kinetic energy) of the

exhaust gases allows for:

(a) Increased engine torque at low speeds

(b) Increased maximum power at high speeds.

Operation at high rotation speeds:

As the rotation speed of the engine increases, there

is a gradual increase in the kinetic energy of the

exhaust gases.

As a result, the speed of the turbine (1) and,

consequently the supercharging pressure, which also

acts on the actuator (3), increases.

The actuator (3), controlled by the solenoid valve, opens

the moving vanes (2) by means of a rod, until the

maximum opening position is reached.

The increase in the section produces a slowing down

of the flow of the exhaust gases passing through the

turbine (1) at speeds which are the same as or less

than the low speed condition.

The speed of the turbine (1) decreases and settles

down at a suitable level for the correct operation of the

engine at high speeds.

1. Turbine

2. Moving vanes

3. Pneumatic actuator

4. Rotary seal